Operating pressure adjustable air exhausting brake

A technology of exhaust braking and working pressure, which is applied in the direction of engine components, engine control, machine/engine, etc., can solve the problems of short braking time, braking lag, unstable back pressure value, etc., and achieve sensitive response and control Smooth and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] In order to understand the structural principle of the present invention more clearly, describe the novelty of the present invention, creativity, and compare with other disclosed engine retarder structures, first to figure 1 , figure 2 for analysis.

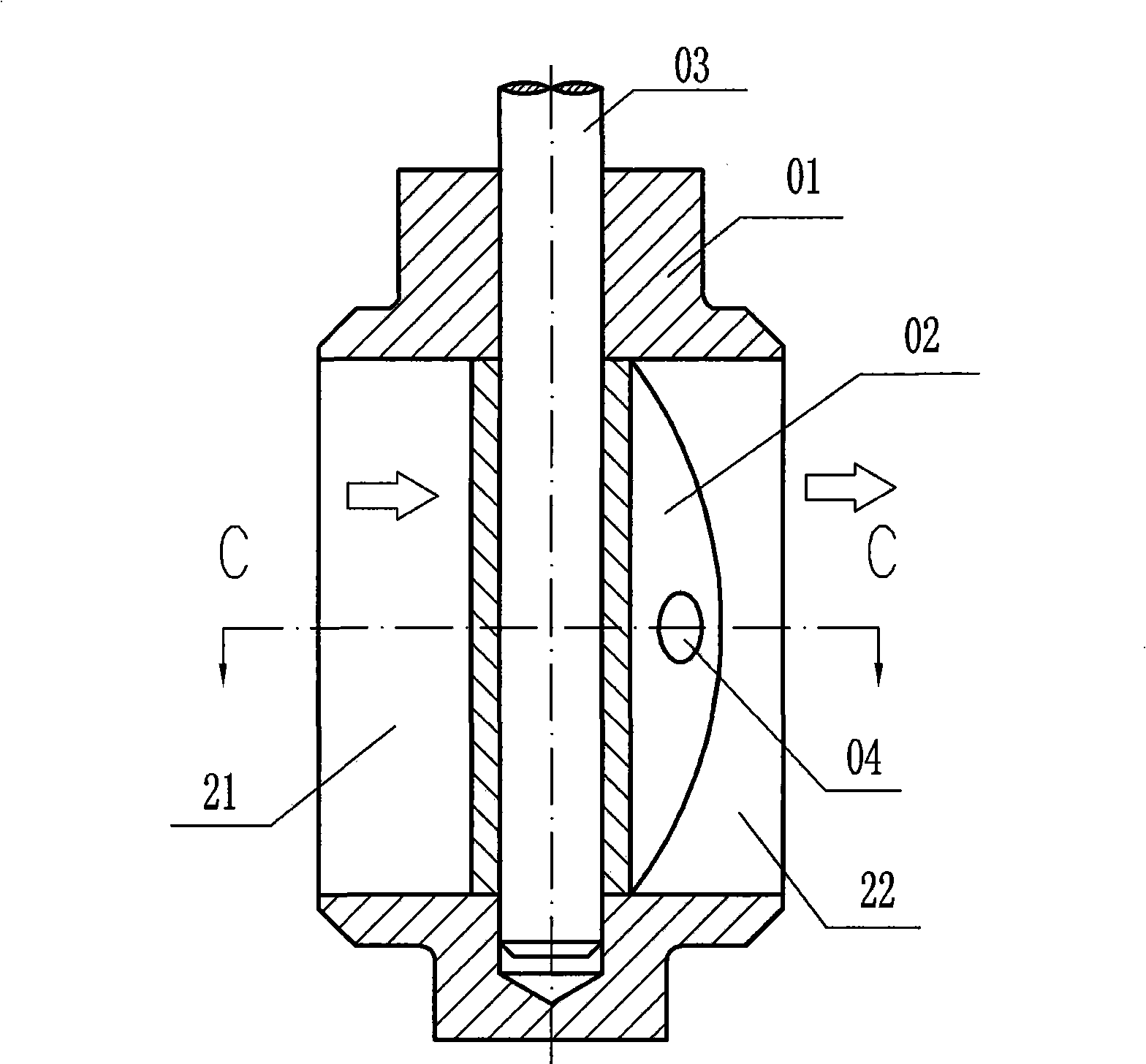

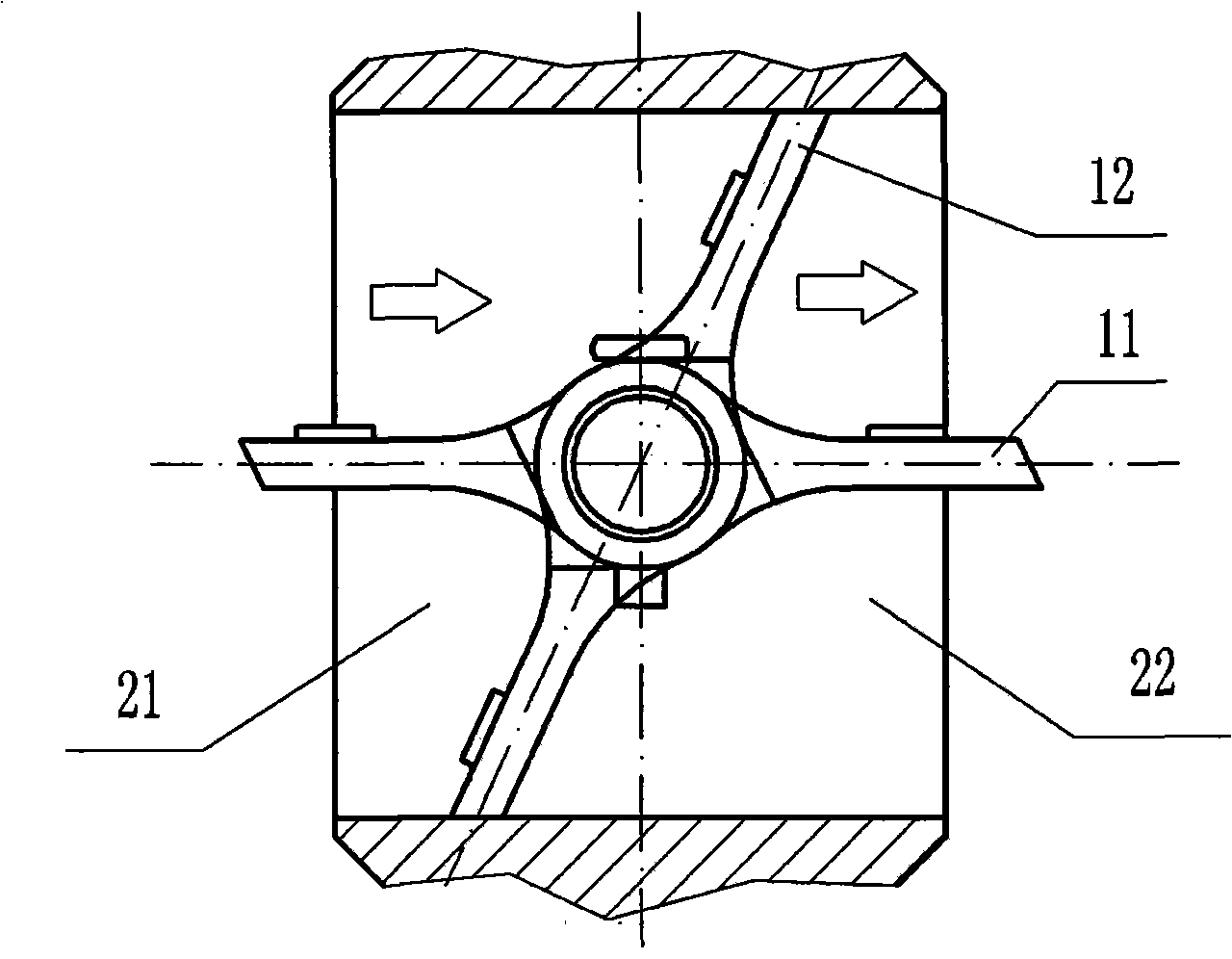

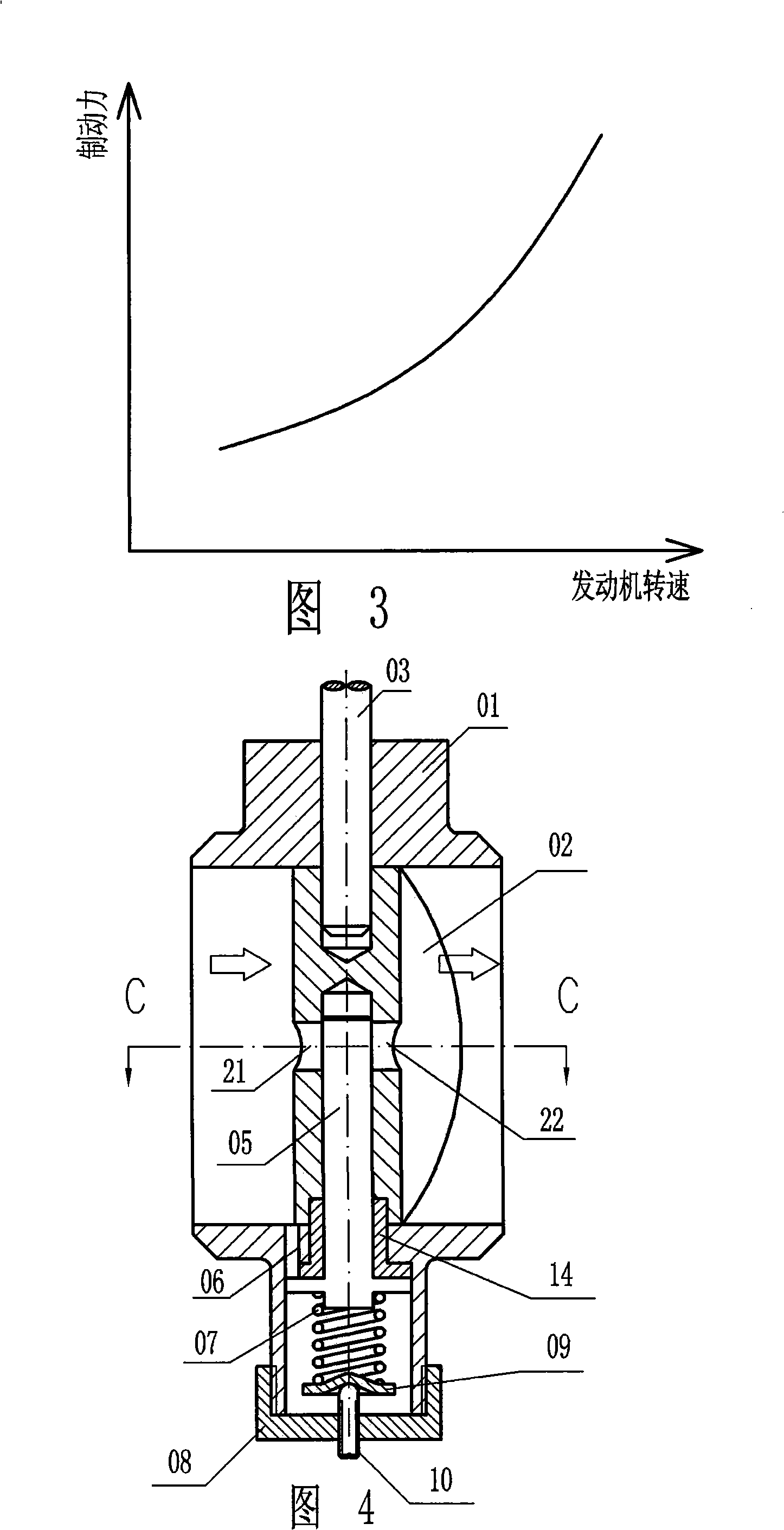

[0020] figure 1 , figure 2 The structure shown is a schematic diagram of an existing exhaust brake, and the support rod 03 fixes the disc 02 at a designated position of the valve body 01 . The direction of the arrow is the flow direction of exhaust gas. 11 indicates that the disc is in an open state, and 12 indicates that the disc is in a closed state. When the exhaust brake is working, the support rod 03 drives the disc 02 to rotate around its axis, so that the disc rotates from position 11 to position 12, thereby closing the exhaust pipe. As the exhaust gas increases, the pressure in the cavity 21 increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com