Flow distributing type hydraulic oscillation circumferential impactor

A shunt type and impactor technology, which is applied in the direction of vibration drilling, drilling equipment, liquid/gas jet drilling, etc., can solve the problems of poor impact effect and short life, and achieve improved rock breaking efficiency, low cost, and good structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described further below:

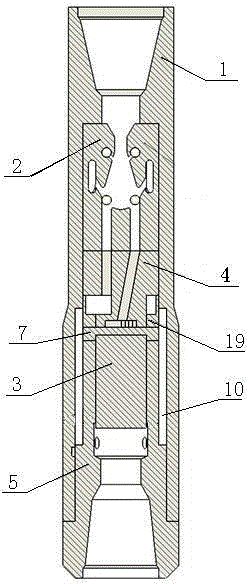

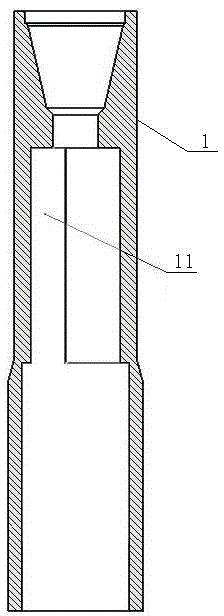

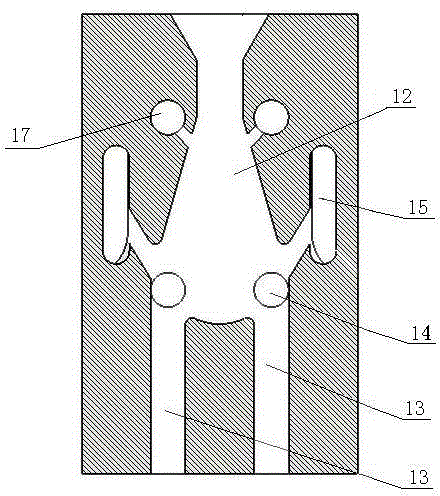

[0024] This shunt type hydraulic oscillation circumferential impactor includes a shell joint 1, a double female jet generator 2, a flow divider 4, a gland 7, a hydraulic hammer 3, and a transmission short 5; the lower end of the shell joint 1 is screwed into the transmission short 5 , the double-female jet generator 2 is placed in the shell joint 1, the hydraulic hammer 3 is located on the upper part of the transmission short-circuit 5, the flow divider 4 and the gland 7 are located between the double-female jet generator 2 and the hydraulic hammer 3, and the transmission short-circuit 5 is screwed into the lower end of the shell joint 1 and pressed against the gland 7; the inner wall of the shell joint 1 has an annular groove 11 and a discharge channel 10, and the annular groove 11 is connected to the liquid return outlet 15 on the outer wall of the double female jet generator 2 Correspondingly set, the discharge chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com