Pressure limiting seal piston and exhaust brake butterfly valve thereof

A sealing piston, exhaust braking technology, applied in the directions of pistons, brakes, brake components, etc., can solve the problems of unstable air pressure, easy resonance, increased noise, etc., to achieve a simple and compact structure, reduce exhaust gas leakage, reduce The effect of small movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

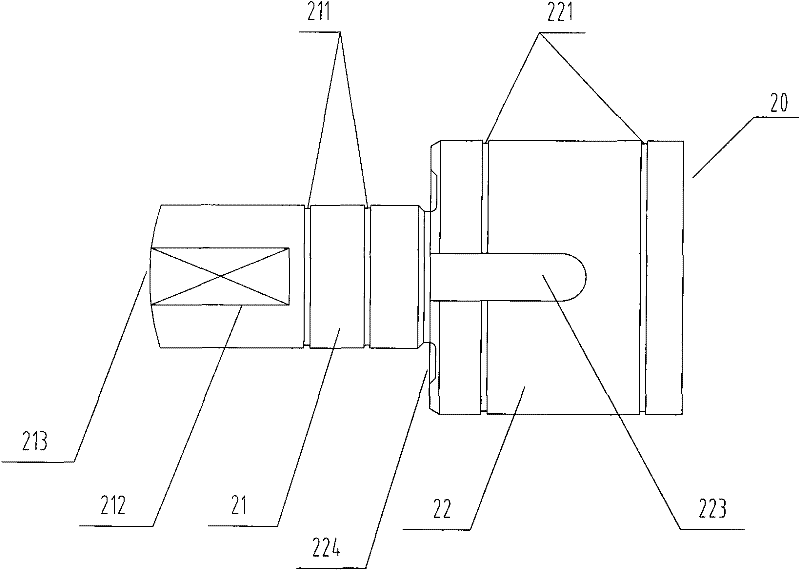

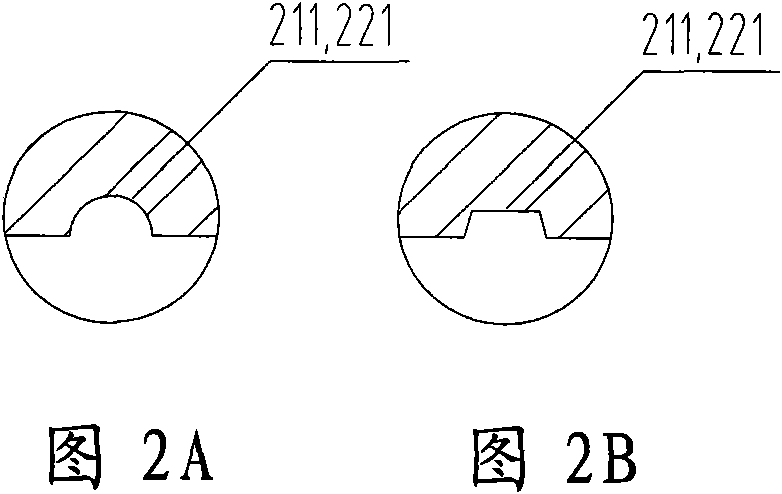

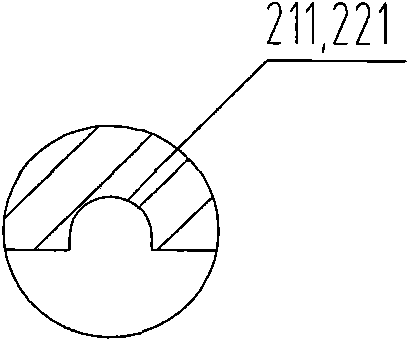

[0042] figure 1 It is a schematic structural diagram of Embodiment 1 of the pressure-limiting sealing piston of the present invention. like figure 1As shown, the present invention provides a pressure-limiting sealing piston 20, including a piston body, the piston body is stepped, and consists of an upper tappet 21 and a lower support 22, the diameter of the tappet 21 is smaller than that of the support 22 A first ring groove 211 is opened on the outer surface of the tappet 21 . According to different needs, the number of the first annular grooves 211 may be one or more than one. When the number of openings is more than one, the interval between two adjacent first annular grooves 211 should not be less than 2 mm. At the same time, a second annular groove 221 is opened on the outer surface of the support 22 . The number of the second ring grooves 221 can also be one or more. When the number of the second ring grooves 221 is more than one, in order to ensure the sealing prope...

Embodiment 2

[0058] In the above-mentioned first embodiment, when the pressure-limiting device of the butterfly valve adopts the structure of a pressure-limiting spring 7, in order to ensure that the pressure-limiting spring 7 is not bent due to the force in its interior, thereby affecting the accuracy of the butterfly valve's setting of the limiting pressure, A spring mounting hole 222 is provided at the rear of the support 22 of the pressure-limiting sealing piston, see image 3 , Figure 4 As shown, the outer diameter of the spring mounting hole 222 is used to locate the compression limiting spring 7, the mounting hole should be designed as a blind hole, and the depth of the blind hole is required to be greater than or equal to twice that of the compression limiting spring 7 in the pre-stressed state. lead, so as to ensure that the pressure-limiting spring 7 is not likely to come out after being stressed.

[0059] Figure 13 It is a sectional view of the second embodiment of the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com