Flameout system of vehicle during exhaust brake

A technology of exhaust braking and vehicles, which is applied in the field of vehicles, can solve the problems of driver misoperation, increase the risk of accidents, increase the wear and tear of brakes, etc., and achieve the effect of high driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

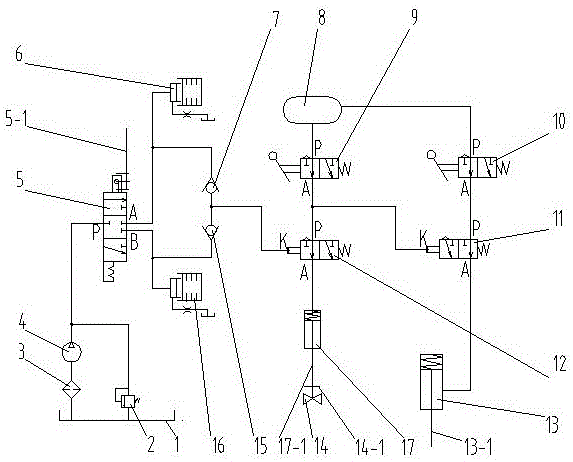

[0013] Such as figure 1 As shown, an exhaust brake flameout system for a vehicle is innovative in that it includes a fuel tank 1, a filter 3, a hydraulic pump 4, a gear selection operation valve 5, a forward gear clutch 6, a first one-way valve 7, an air Package 8, exhaust butterfly valve switch 9, flameout switch 10, air control valve 11, hydraulic control air valve 12, flameout cylinder 13, exhaust butterfly valve 14, second one-way valve 15, reverse gear clutch 16 and butterfly valve cylinder 17, all The gear selection operation valve 5 includes a joystick 5-1, and the joystick 5-1 is connected with a gear selector located in the cab through a flexible shaft;

[0014] The oil inlet of the hydraulic pump 4 communicates with the fuel tank 1 through the filter 3, the oil outlet of the hydraulic pump 3 communicates with the oil inlet P of the gear selection operation valve 5, and the execution port A of the gear selection operation valve 5 passes through The two oil passages c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com