Exhaust brake

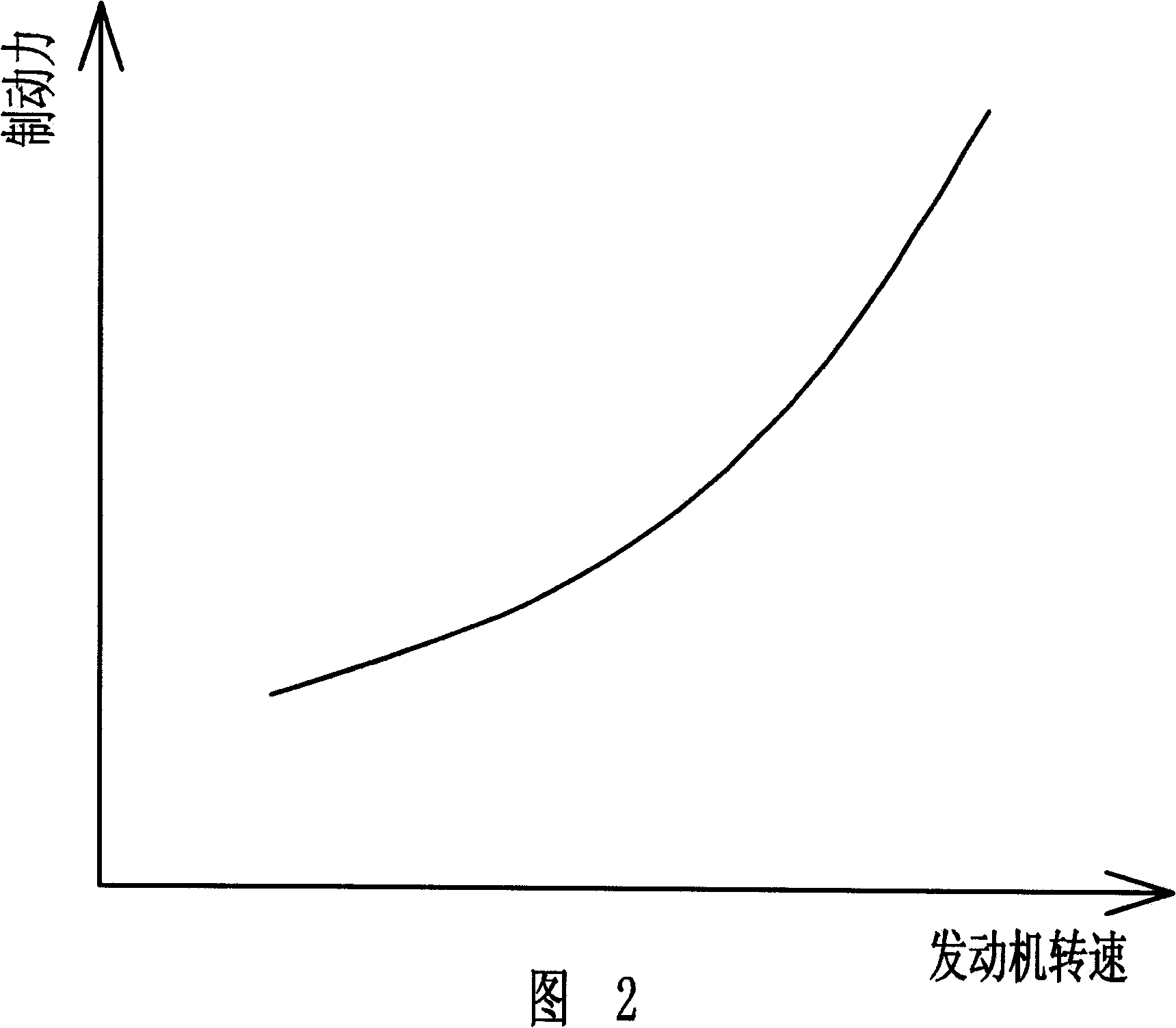

An exhaust brake and brake technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of non-adjustment, brake lag, unstable back pressure, etc., to achieve sensitive response, stable and reliable braking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

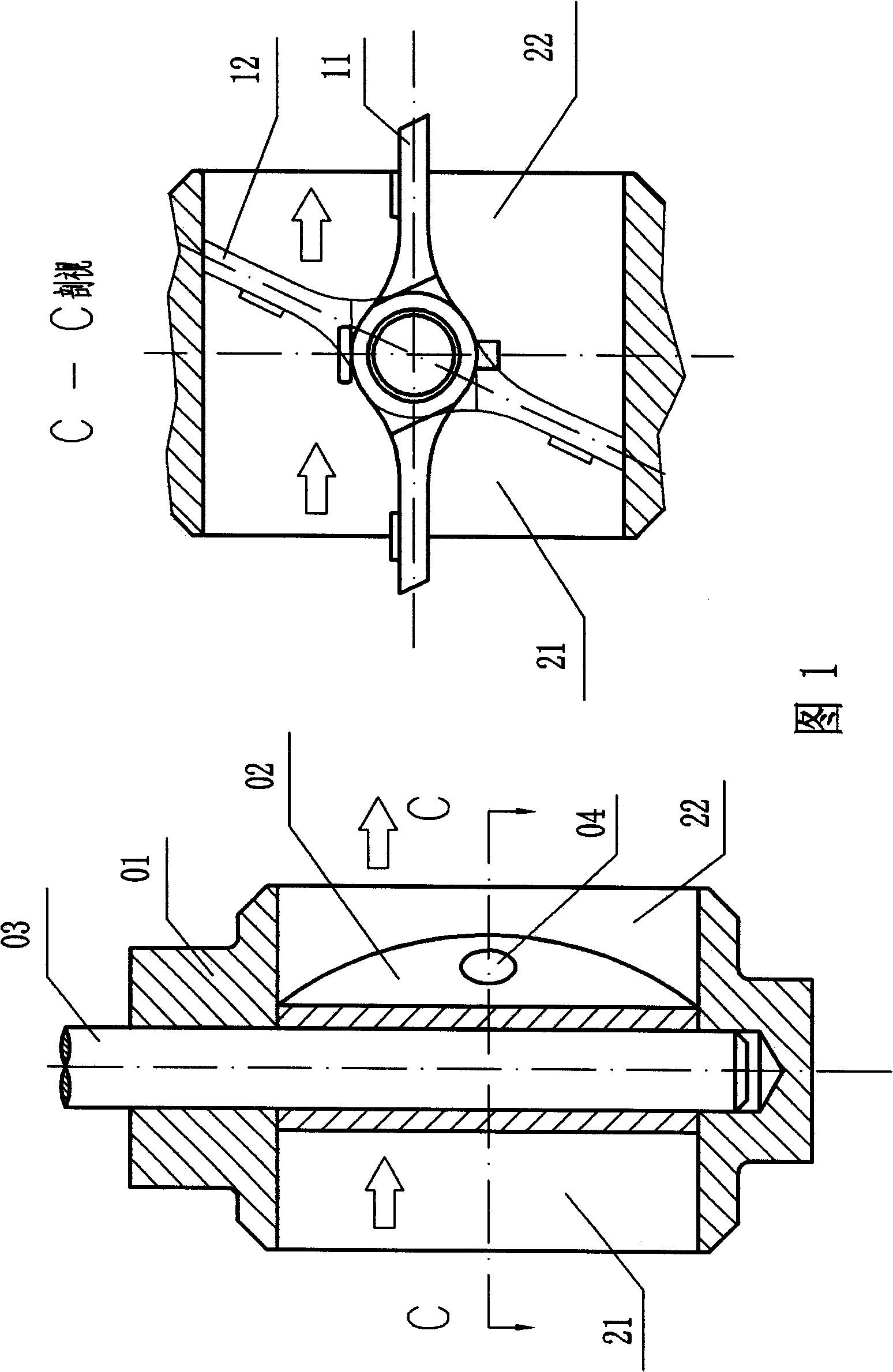

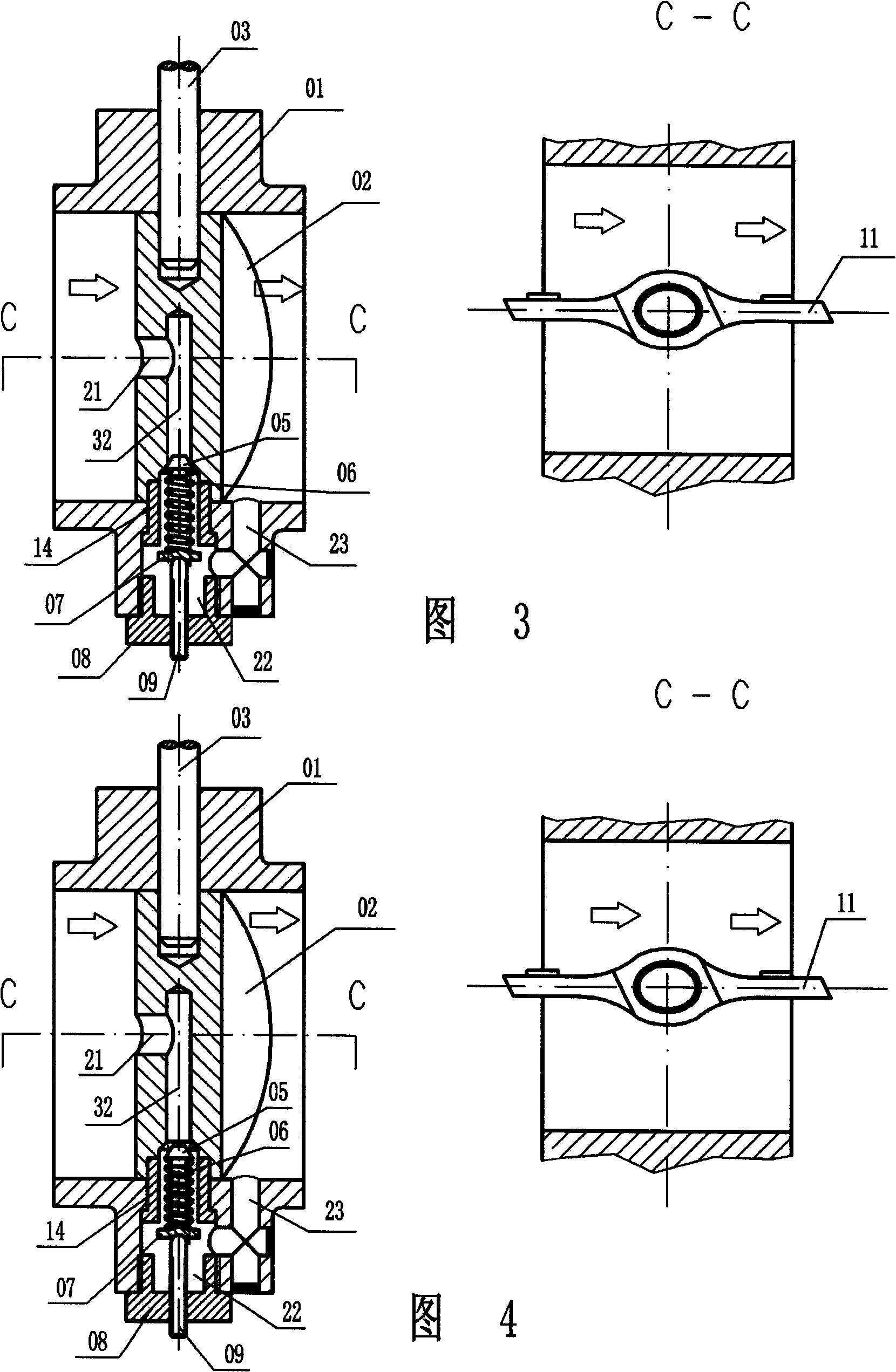

[0024] The specific implementation manner of the present invention will be introduced below with reference to FIG. 3 and FIG. 4 . Figure 3 shows that the exhaust gas channel is in a disconnected state, and Figure 4 shows that the exhaust gas channel is in an open state. All parts with the same function as before in Fig. 3 and Fig. 4 use the same number.

[0025] The valve body 01 is used to assemble the components that complete the braking function into an assembly, the support rod 03 and the support sleeve 14 are used to fix the disc 02 at the designated position of the valve body 01, and the direction of the arrow represents the flow direction of the exhaust gas. There are cavity 21 and cavity 22 on the disc 02, and a pressure reducing valve 05 is pressed on the bottom of cavity 22 by spring 06, pressure plate 07, adjustment support 09 and cover 08. At this time, the pressure reducing valve 05 connects cavity 22 and cavity 32 It is divided into two parts; when no braking is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com