Engine exhaust brake control system and control method

An exhaust braking and control system technology, applied in the field of modern transportation, can solve the problems of secondary opening of the exhaust valve, shorten the service life of exhaust valve components, and reduce the auxiliary braking efficiency, so as to prolong the service life and brake The effect of increased potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

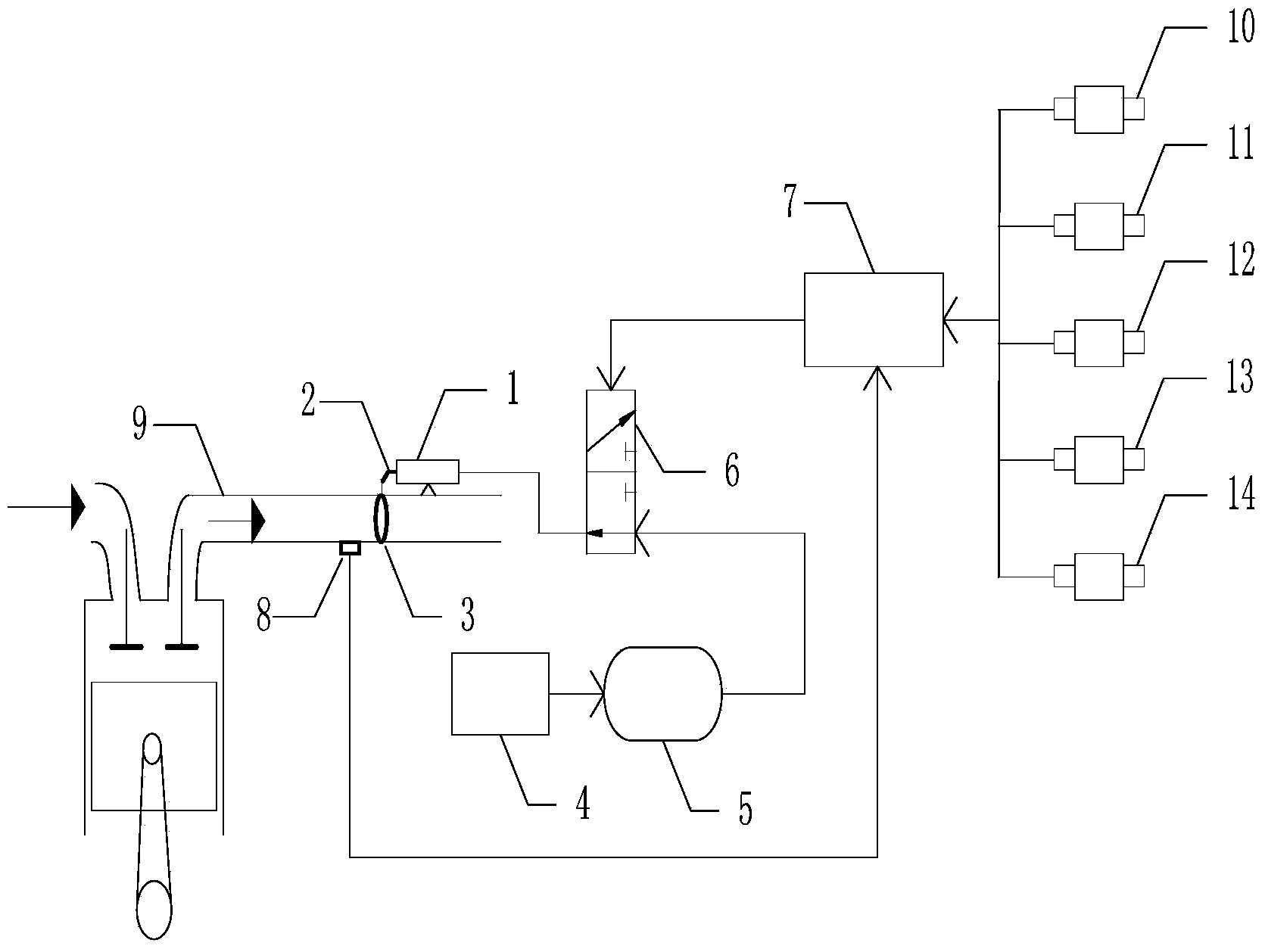

[0019] The present invention is made up of signal acquisition unit, control unit 7 and executive mechanism three parts, as figure 1 shown. The signal acquisition part includes a brake pedal position sensor 10 , a clutch position sensor 11 , an engine speed sensor 12 , a brake disc temperature sensor 13 , a high temperature pressure sensor 8 and a throttle position sensor 14 . The control unit 7 is a microprocessor, which can analyze and process the collected information. The actuator consists of an exhaust brake cylinder 1, a rocker mechanism 2, a butterfly valve 3, a compressor 4, an air storage tank 5 and a solenoid valve 6.

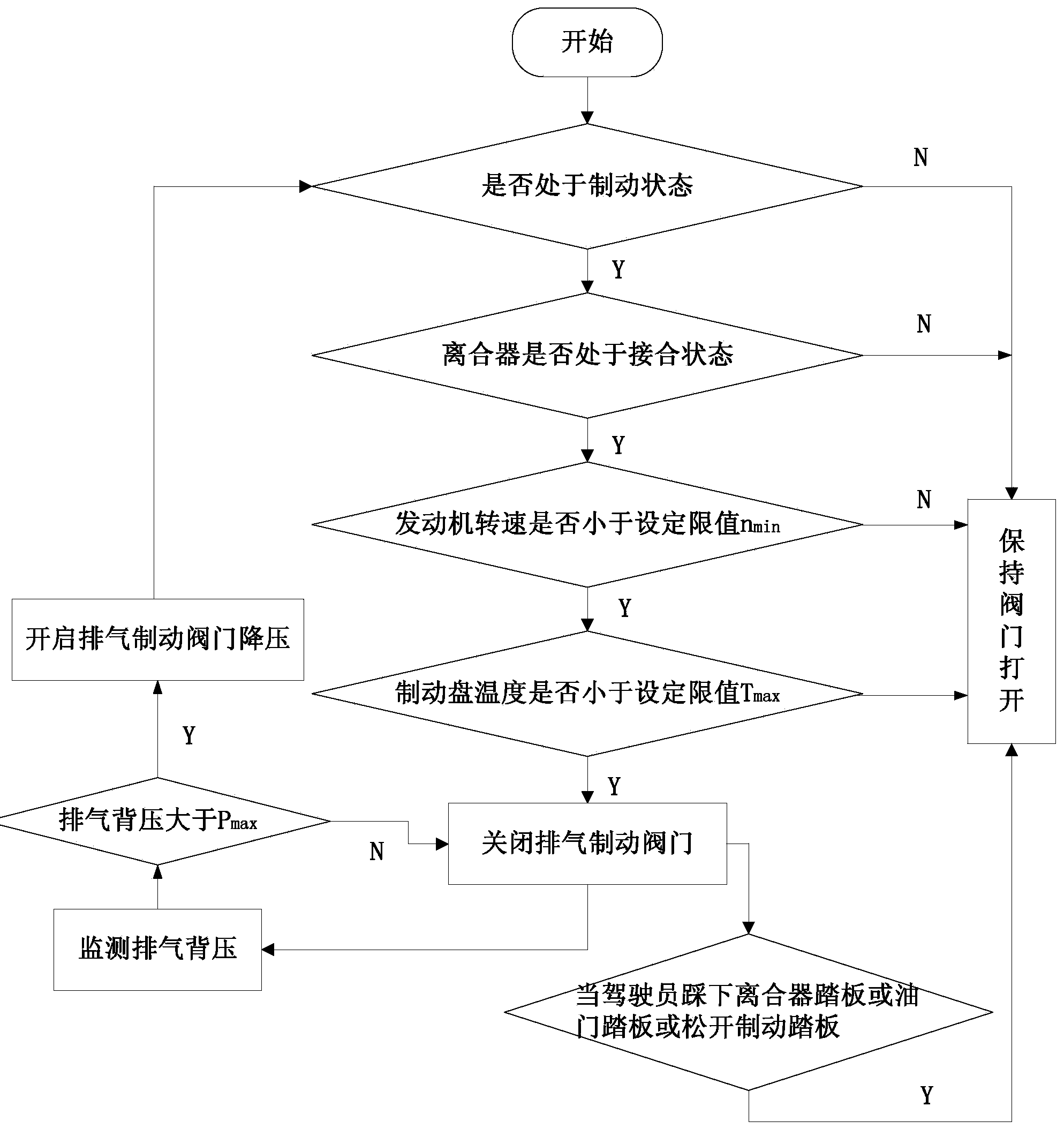

[0020] The control process of the present invention includes three parts: exhaust brake automatic opening control, pressure regulation feedback control and exhaust brake automatic end control. The specific control process is as figure 2 mentioned.

[0021] Such as figure 1 and figure 2 As shown, the automatic opening control of the exhaust brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com