Single-cam-shaft switch pivot type variable-mode air valve driving system

A driving system and camshaft technology, applied in the direction of valve driving devices, engine components, machines/engines, etc., can solve the problems of easy damage to contact parts, large inertial force of rocker arm movement, and large number of moving parts, so as to reduce movement number of parts, compact system structure, and high system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

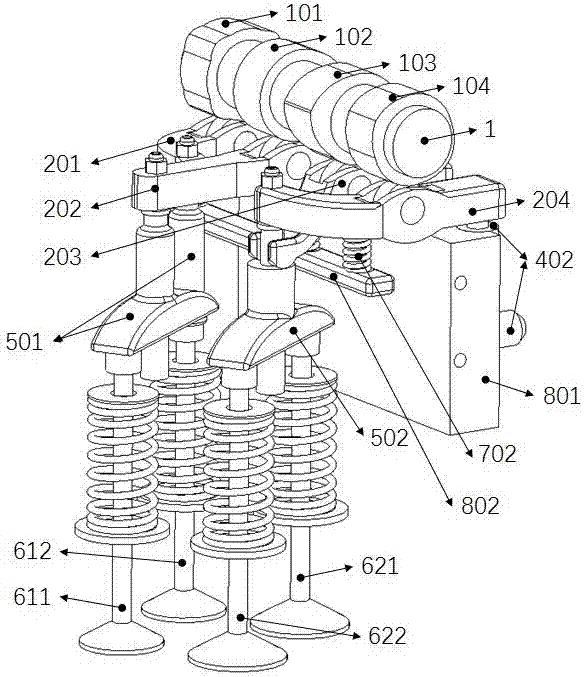

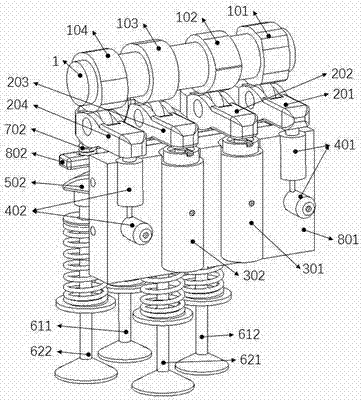

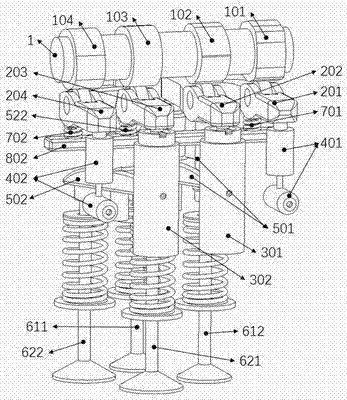

[0046] The invention relates to a single camshaft switch fulcrum type variable mode valve drive system. It includes exhaust valve assembly and intake valve assembly. It also includes a cam arranged on the camshaft 1, a rocker arm, two driving fulcrum assemblies and two braking fulcrum assemblies installed on the fixing piece, and a rocker arm return spring. The cams include an exhaust braking cam 101 , an exhaust driving cam 102 , an intake driving cam 103 and an intake braking cam 104 . The rocker arm includes an exhaust brake rocker arm 201 , an exhaust drive rocker arm 202 , an intake drive rocker arm 203 and an intake brake rocker arm 204 . The drive fulcrum assembly includes an exhaust drive fulcrum assembly 301 and an intake drive fulcrum assembly 302 . The brake fulcrum assembly includes an exhaust brake fulcrum assembly 401 and an intake brake fulcrum assembly 402 . The rocker arm return spring includes an exhaust brake rocker arm return spring 701 and an intake bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com