Gas control reversing valve detection device and detection method

A technology of air-controlled reversing valves and detection devices, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of low detection efficiency and detection accuracy, lack of detection, etc., and achieve high testing efficiency, High clamping precision, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

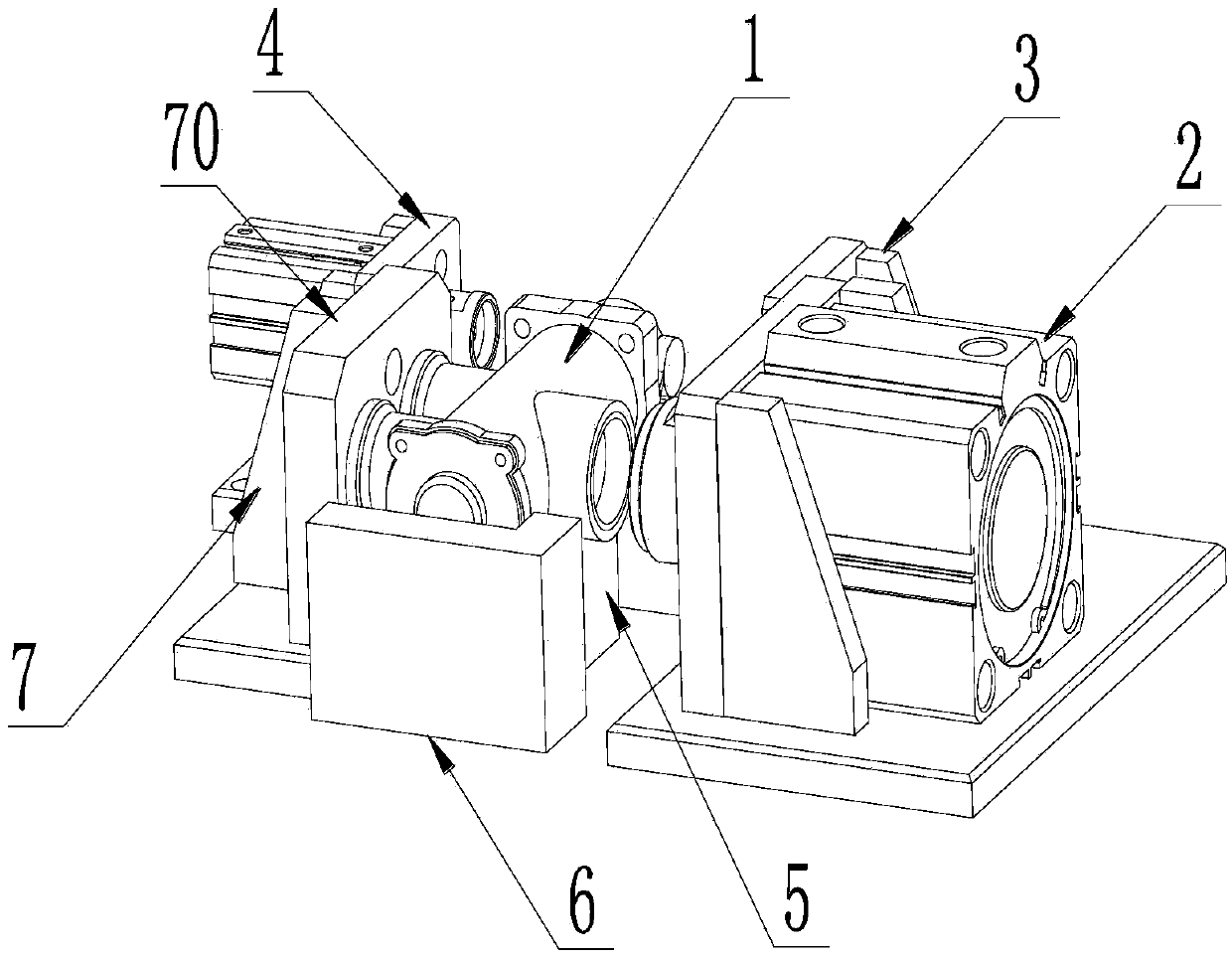

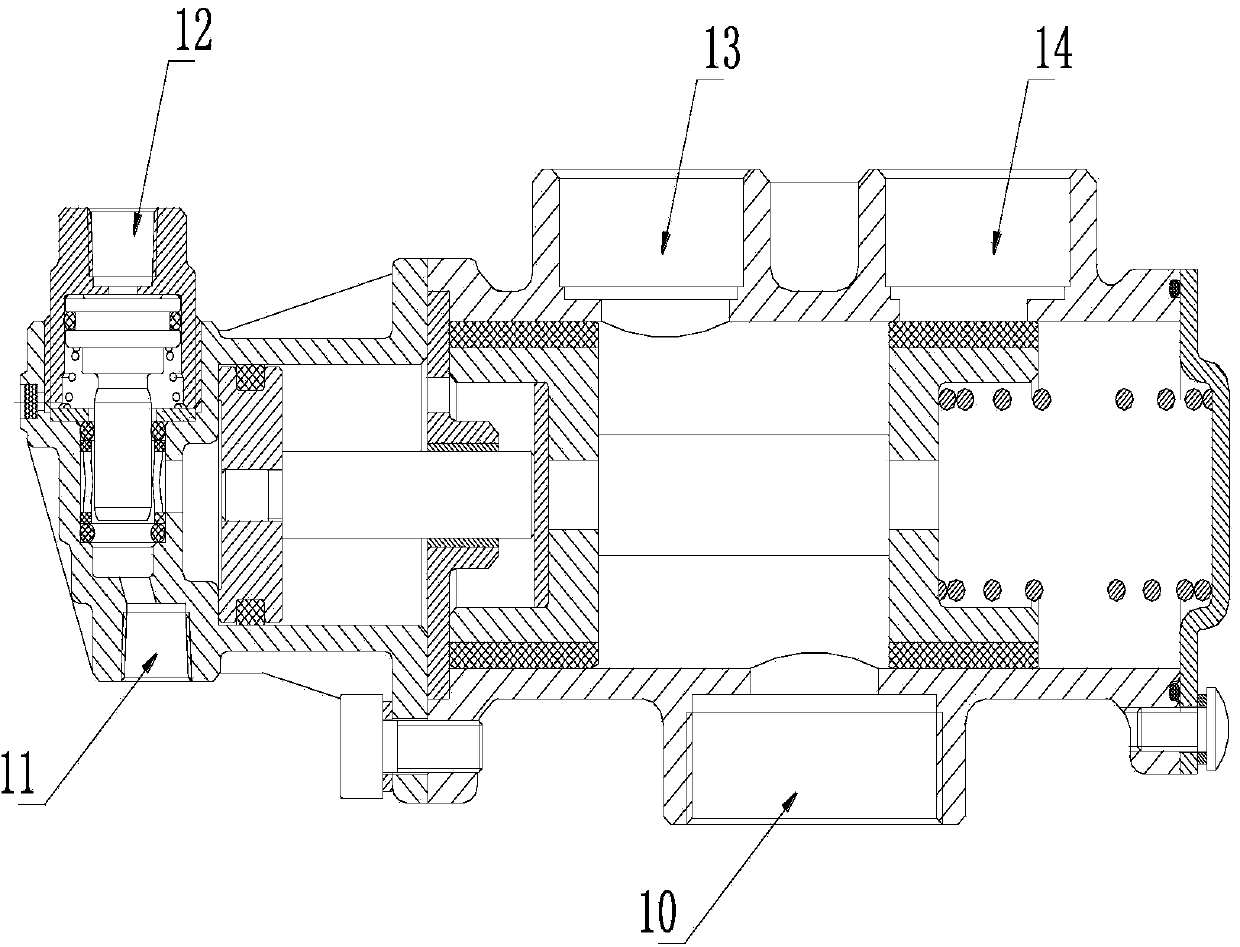

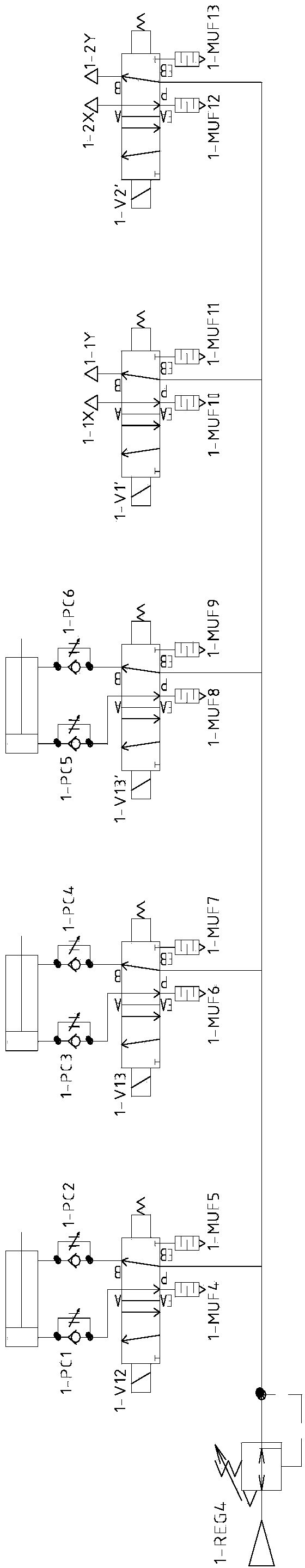

[0015] refer to figure 1 , figure 2 , a detection device for an air-controlled reversing valve of the present invention is fixed on a stand, and includes a cylinder tooling 2 for blocking the air compressor inlet port 2 and 10 of the air-controlled reversing valve 1, and a cylinder tooling 2 for blocking the air-controlled reversing valve. The pressure regulating valve inlet port 41 of valve 1 is the right cylinder tooling 3 of port 11, and the left cylinder tooling 4 of the exhaust brake valve control port 42 port 12 of the air control reversing valve 1 is blocked. head; the air inlet of the cylinder makes the plug connected with the cylinder protrude forward to block the interface of the air control valve 1; the positioning seat 5 for fixing the air control valve 1 is also installed on the platform, One end of the positioning seat 5 is provided with a limit seat 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com