Variable-mode valve driving system

A driving system and valve technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., can solve the problems of difficult processing, complex oil circuit, large quality, etc., and achieve extended service life, low cost and low cost. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

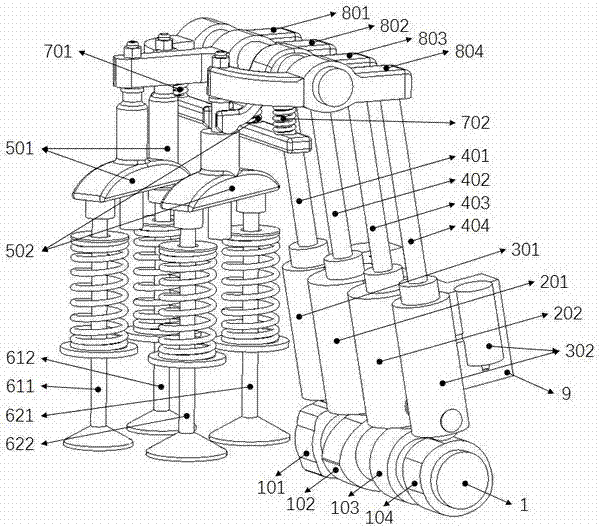

[0033] The invention relates to a variable mode valve drive system. It includes an intake valve assembly and an exhaust valve assembly. It also includes a cam arranged on the camshaft 1, two drive fulcrum components and two brake fulcrum components mounted on a fixed part, push rod, rocker arm, rocker Arm reset mechanism. The cam includes an exhaust brake cam 101, an exhaust drive cam 102, an intake drive cam 103, and an intake brake cam 104. The drive fulcrum assembly includes an exhaust drive fulcrum assembly 201 and an intake drive fulcrum assembly 202. The brake fulcrum assembly It includes an exhaust brake fulcrum assembly 301 and an intake brake fulcrum assembly 302. The push rods include an exhaust brake push rod 401, an exhaust drive push rod 402, an intake drive push rod 403 and an intake brake push rod 404, The rocker arm includes an exhaust brake rocker arm 801, an exhaust drive rocker arm 802, an intake drive rocker arm 803, and an intake brake rocker arm 804. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com