Engine exhaust gas waste heat recovery and control system and method based on organic rankine cycle

A Rankine cycle and exhaust waste heat technology, which is applied in the cooling of machines/engines, engine components, and engines, can solve the problems of engine performance impact, low thermoelectric conversion efficiency, and no working medium recovery device, etc., to reduce Effects of heat pollution, convenient start-up and rapid shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

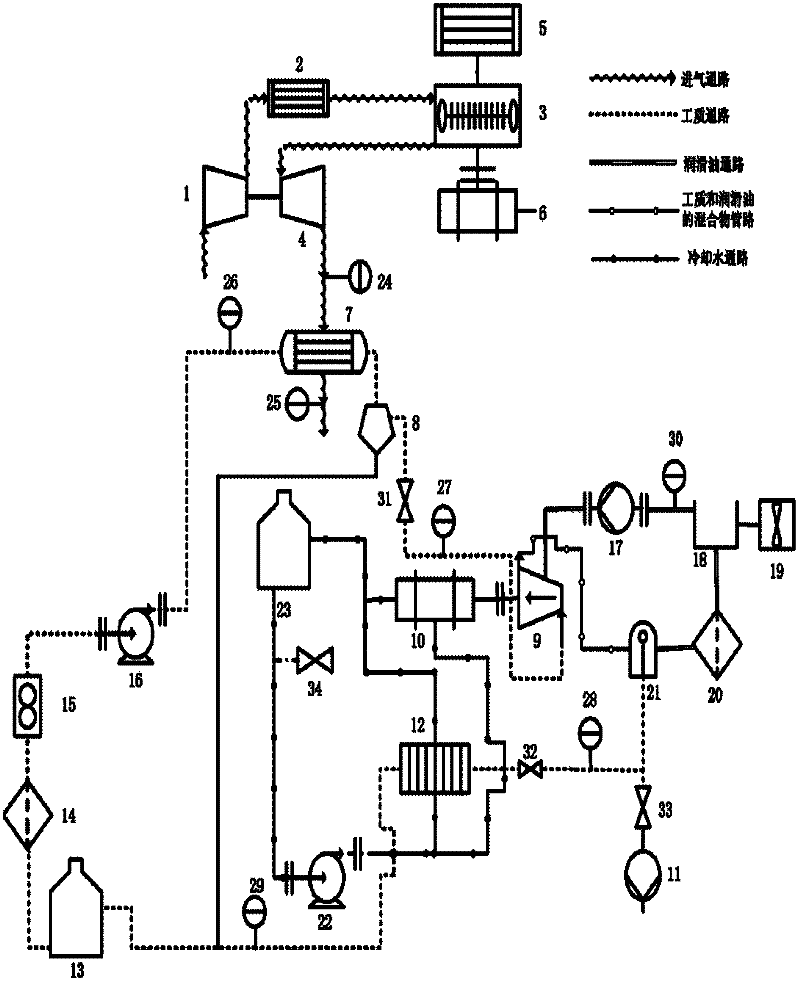

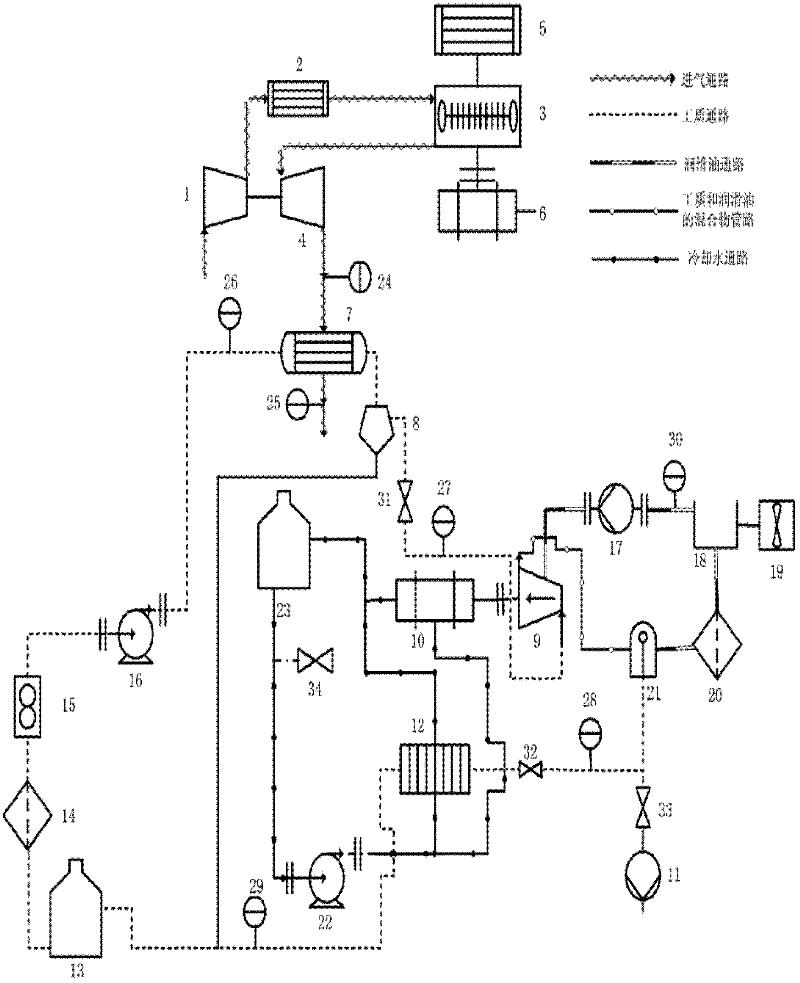

[0021] The present invention is based on the organic Rankine cycle engine exhaust waste heat recovery control system, and its connection diagram is as follows figure 1 As shown, there are four cycles including engine cycle, organic Rankine cycle, cooling water cycle and lubricating oil cycle. It also describes in detail the operation process of the system starting, running, stopping, and when the system breaks down, it can be used for emergency braking.

[0022] First start the organic Rankine cycle, first use the vacuum pump 11 to vacuumize the whole system to ensure that the working medium will not leak into the environment, and close the third valve 33 after completion. Then fill the system with nitrogen from the liquid storage tank 13. On the one hand, the air in the system is emptied, because there is water vapor in the air. drag loss. On the one hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com