Steel-tube square reinforced concrete member and preparation method thereof

A reinforced concrete and concrete technology, applied in pillars, piers, columns, etc., can solve the problems of complex calculation methods and difficult processing of circular stirrups, and achieve the effects of reducing costs, improving fire resistance and improving construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Steel pipe square reinforced concrete member

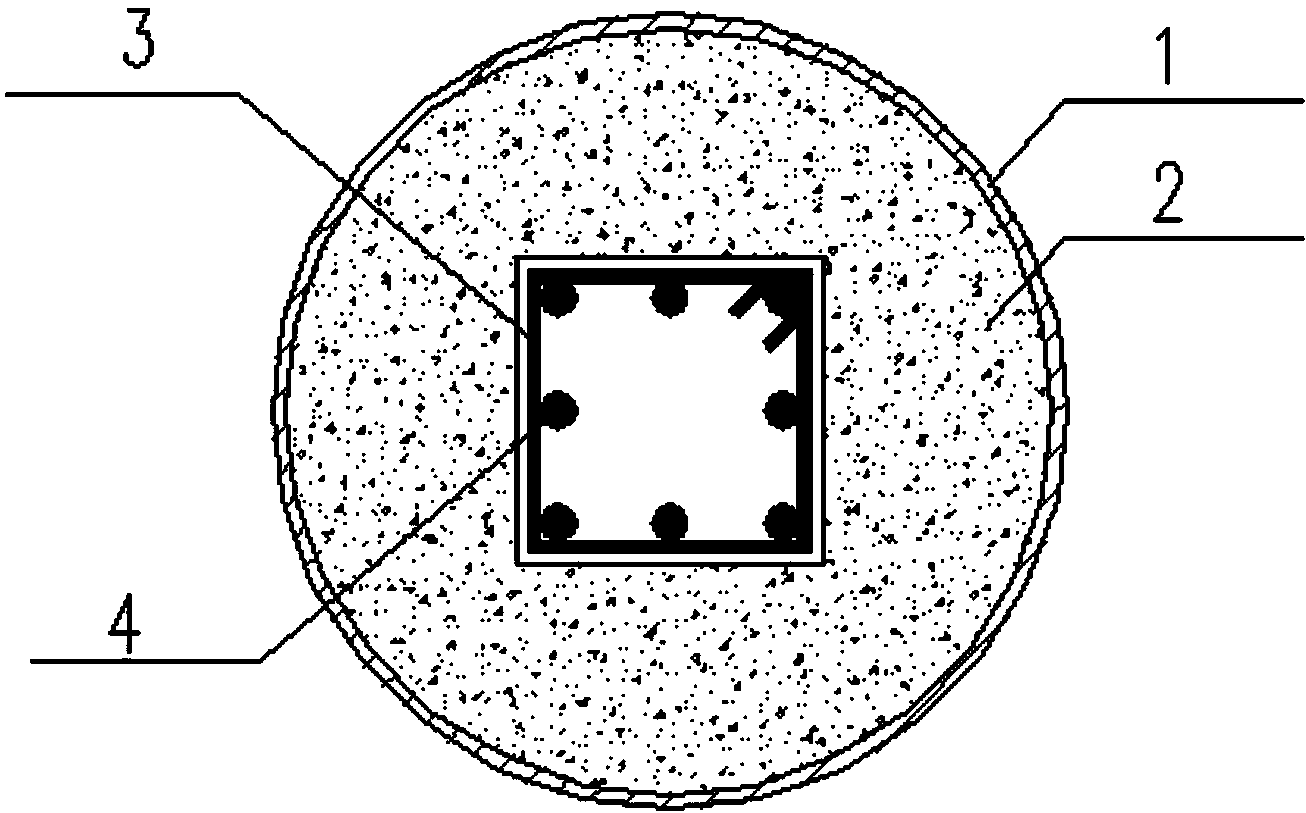

[0030] as attached figure 1 As shown, a steel pipe square reinforced concrete member includes a steel pipe 2, concrete 2 and internal steel bars, wherein the internal steel bars are surrounded by concrete and placed inside the steel pipe 1, and the internal steel bars include square stirrups 2 and longitudinal bars 3. The ribs are arranged along square stirrups.

[0031] The cross-sectional size of the entire steel pipe square reinforced concrete is 800mm×4mm×1500mm, the size of the square stirrup is 300mm×300mm, and the diameter of the longitudinal bar is 8mm. One stirrup is arranged every 100mm along the square, and three longitudinal bars are placed evenly on each side. 8, tied and connected with square stirrups.

[0032] The bearing capacity of the square reinforced steel pipe concrete structure is higher than that of the plain steel pipe concrete structure, but lower than that of the circular steel pipe ...

Embodiment 2

[0033] Embodiment 2 steel pipe square reinforced concrete member

[0034] A steel pipe square reinforced concrete member, comprising a steel pipe 2, concrete 2 and internal steel bars, wherein the internal steel bars are surrounded by concrete and placed inside the steel pipe 1, the internal steel bars include square stirrups 2 and longitudinal bars 3, and the longitudinal bars are along the square Stirrup configuration.

[0035] According to the scheme of embodiment 1, the section size of the whole steel pipe square reinforced concrete, the size of the square stirrup, the diameter of the longitudinal bar, the number and position of the setting, and the binding connection of the square stirrup can be determined according to the actual use conditions, in embodiment 1 Adjust and optimize the program.

[0036] The bearing capacity of the square reinforced steel pipe concrete structure is higher than that of the plain steel pipe concrete structure, but lower than that of the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com