Gas pressure relief method of ground drilling extraction minery and goaf

A technology for ground drilling and gobs, which is applied in the direction of gas discharge, earthwork drilling, and mining fluids, etc. It can solve the problems of difficult coal seam fracturing, large gas flow attenuation coefficient in drilling holes, and soft coal seams, etc., to reduce gas surges The effect of output volume, elimination of outstanding risk, and increase of air permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

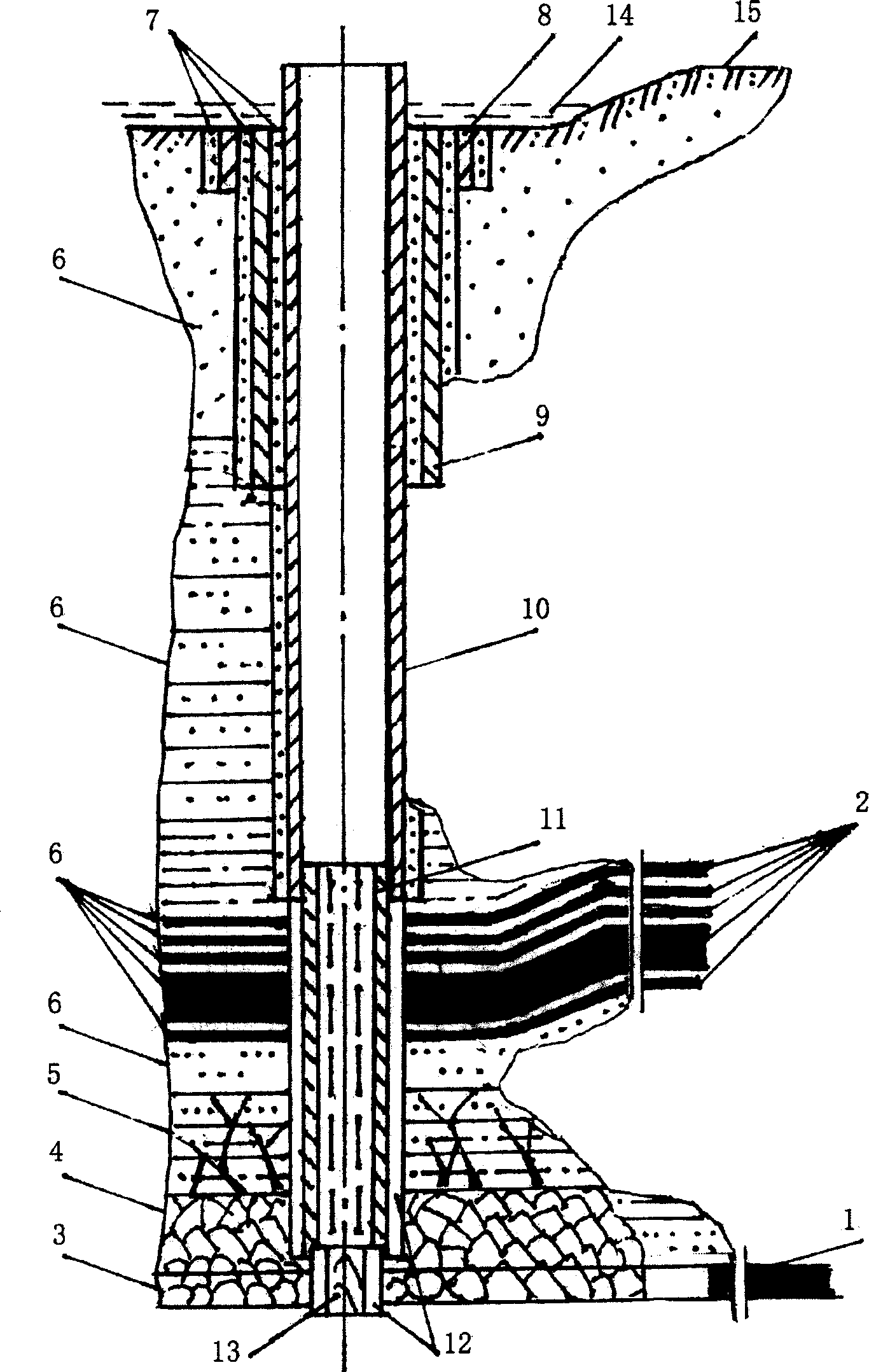

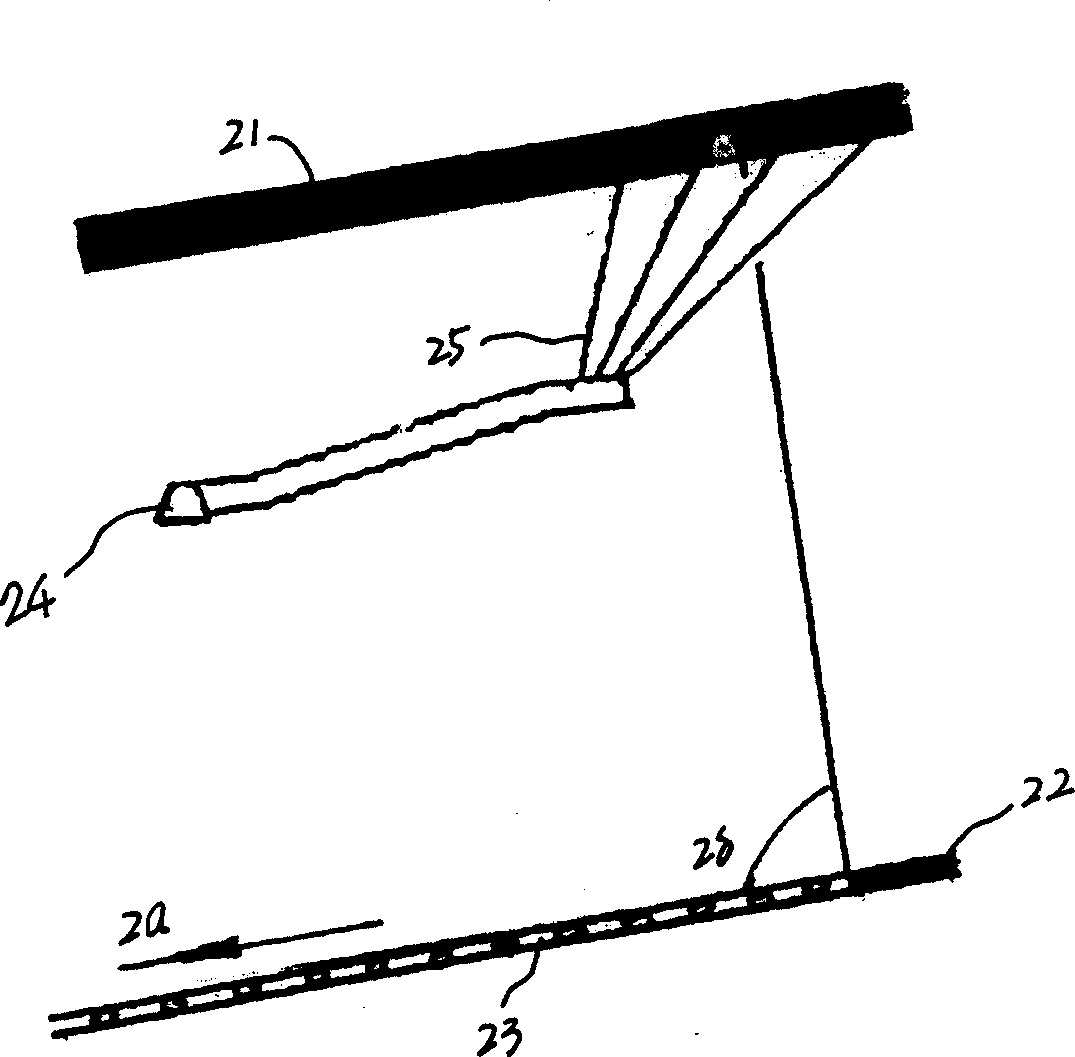

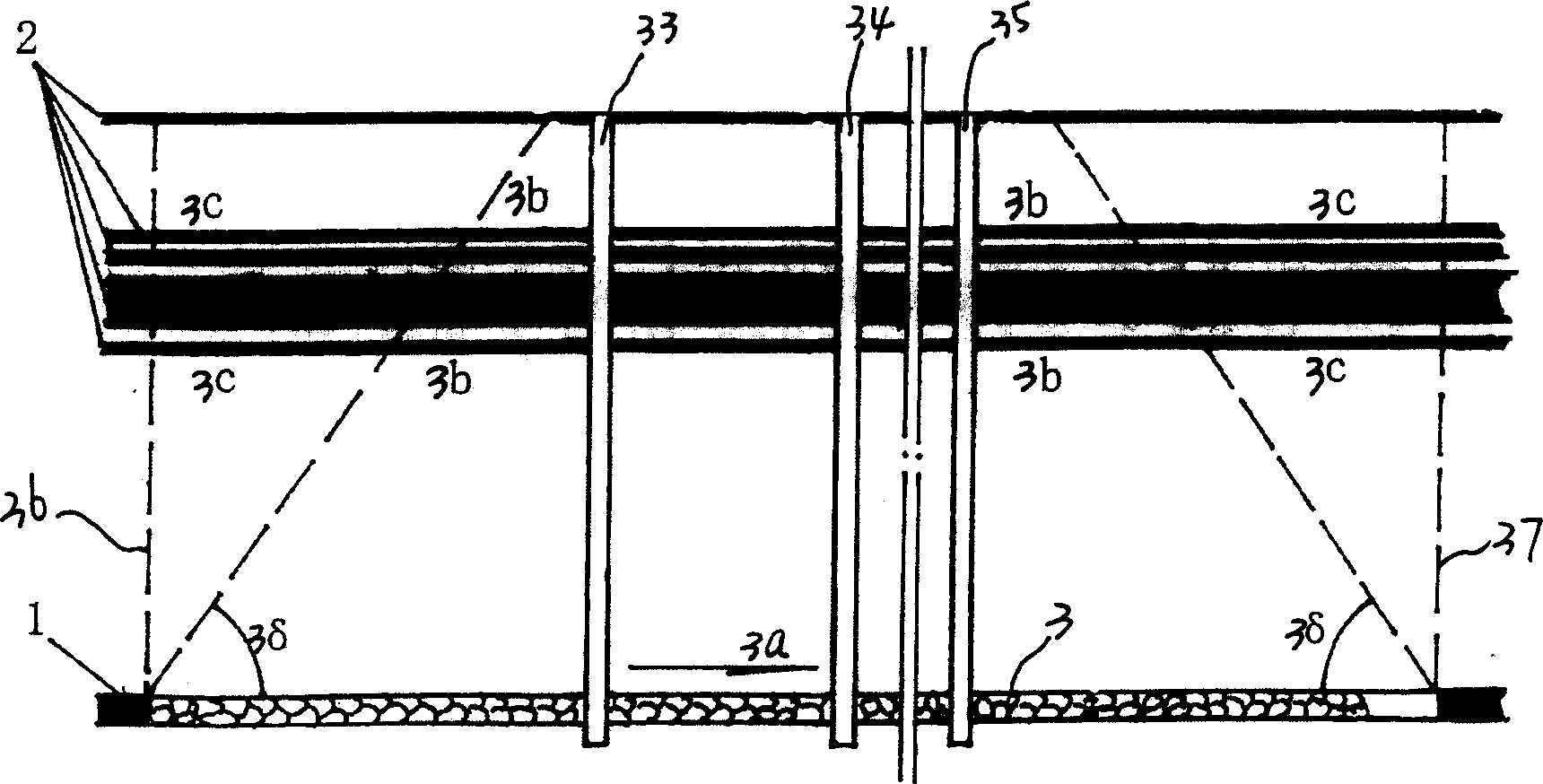

[0038] see figure 1 Before coal mining starts at the mining face of the coal seam 1 in the lower part of the coal seam group or before the overlying coal seams 2 are not affected by the mining of the working face of the lower mining coal seam 1, advance from the ground 15 to the long-distance, low-permeable, high-gas, Prominent and soft overlying coal seams 2 penetrate the layer ground and drill wells 12; and then mining coal seams 1 at the lower part of the overlying coal seams 2 with interlayer distances of 66.7m-96.8m and relative interlayer distances of 35-51 times. A large amount of coal is mined in the working face of the lower mining coal seam 1, so a large mining layer goaf 3 is formed behind the mining face, and a continuous pressure relief space is formed in the goaf 3, and the rock strata above the pressure relief space and The overlying coal seams 2 begin to deform and displace in the direction of the goaf pressure relief space due to the pressure relief during min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com