Method for Prevention and Control of Rockburst by Man-made Spatial Defects

A technology of rock burst and space, applied in ground mining, earth drilling, underground mining, etc., can solve problems such as insufficient energy release, achieve a wide range of energy release, and reduce the impact risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

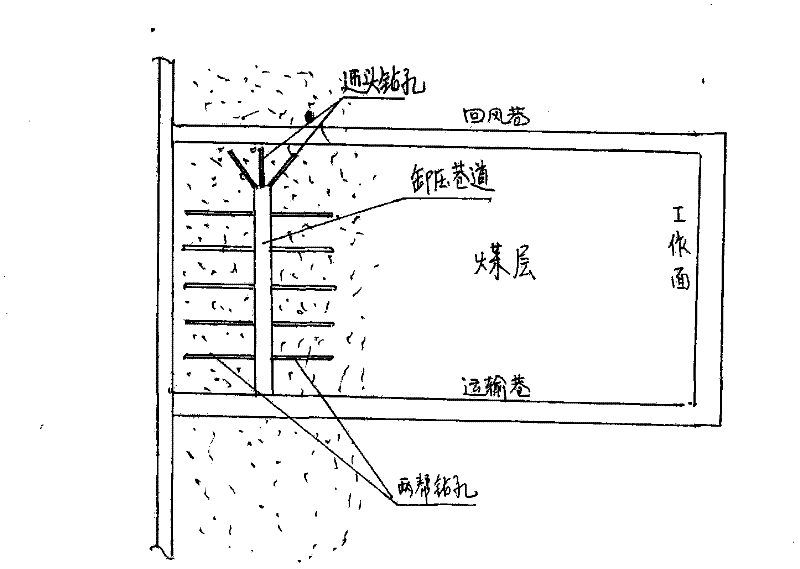

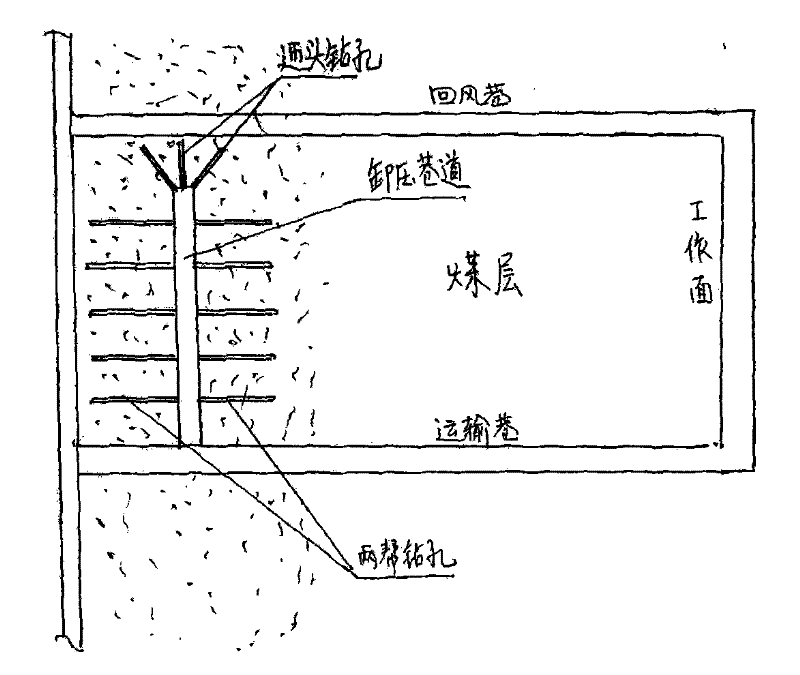

[0012] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0013] Step 1: After the mining system is formed in the working face, firstly delineate the dangerous areas of rock burst, and delineate the most dangerous areas such as figure 1 In the high stress area shown, in the high stress area, excavate a pressure relief roadway with a sectional area of 6-8m 2 , the pressure relief roadway runs through the high stress area, and this kind of pressure relief roadway is called a man-made space defect body; the pressure relief roadway is excavated by blasting, simple temporary support, monitoring, pressure relief and excavation at the same time;

[0014] Step 2: Drilling and blasting of roadway side body

[0015] After the excavation of the pressure relief roadway is completed, three head-on drilling holes with an elevation angle of 3-5° are drilled at the head of the excavation. The diameter of the head-on drilling holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com