Non-pillar sublevel caving mining method for direct loading for ore

A technology of segmental caving and no bottom pillar, applied in surface mining, underground mining, special mining, etc., can solve the problems of short service life, easy collapse, high maintenance cost, high ore recovery rate, wide application range, production safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

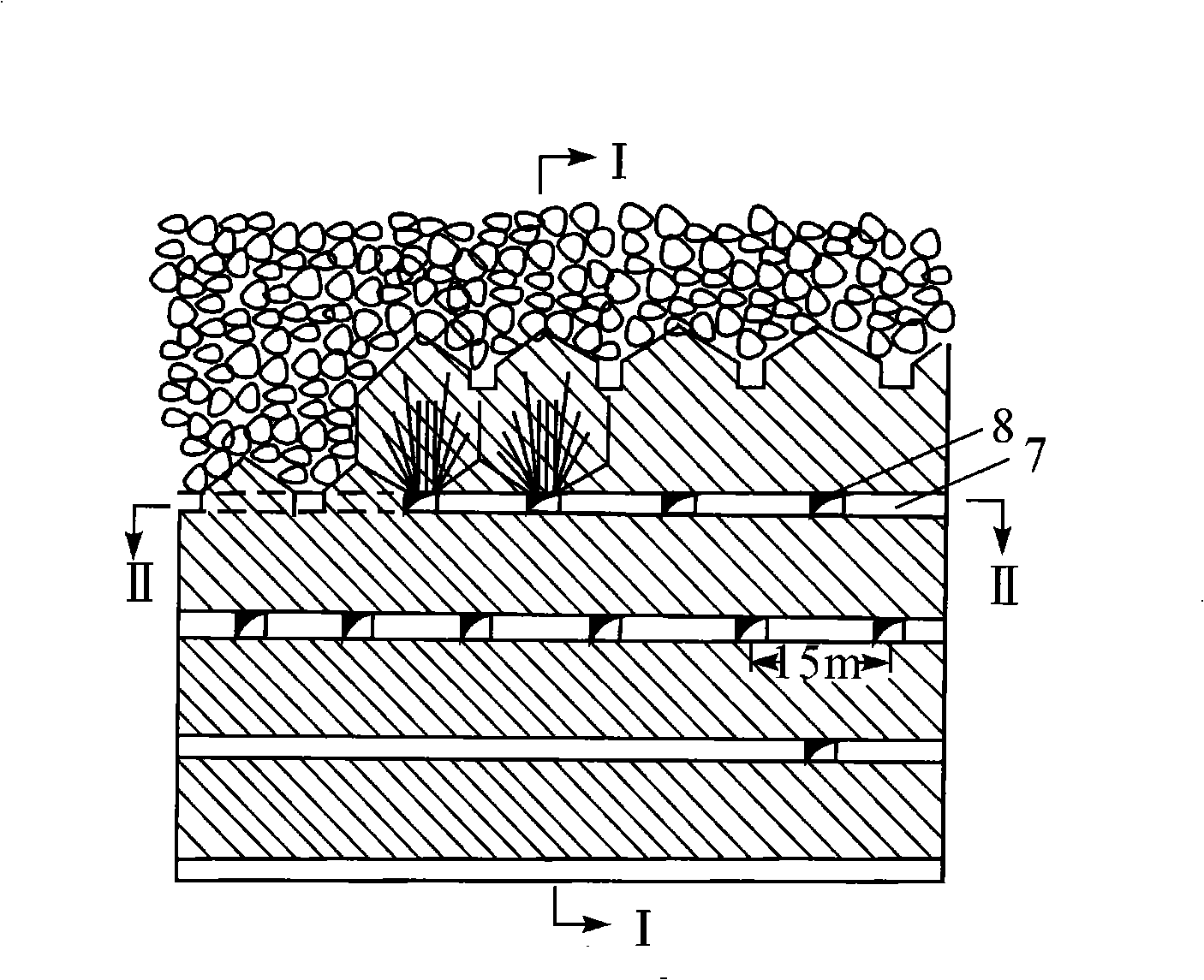

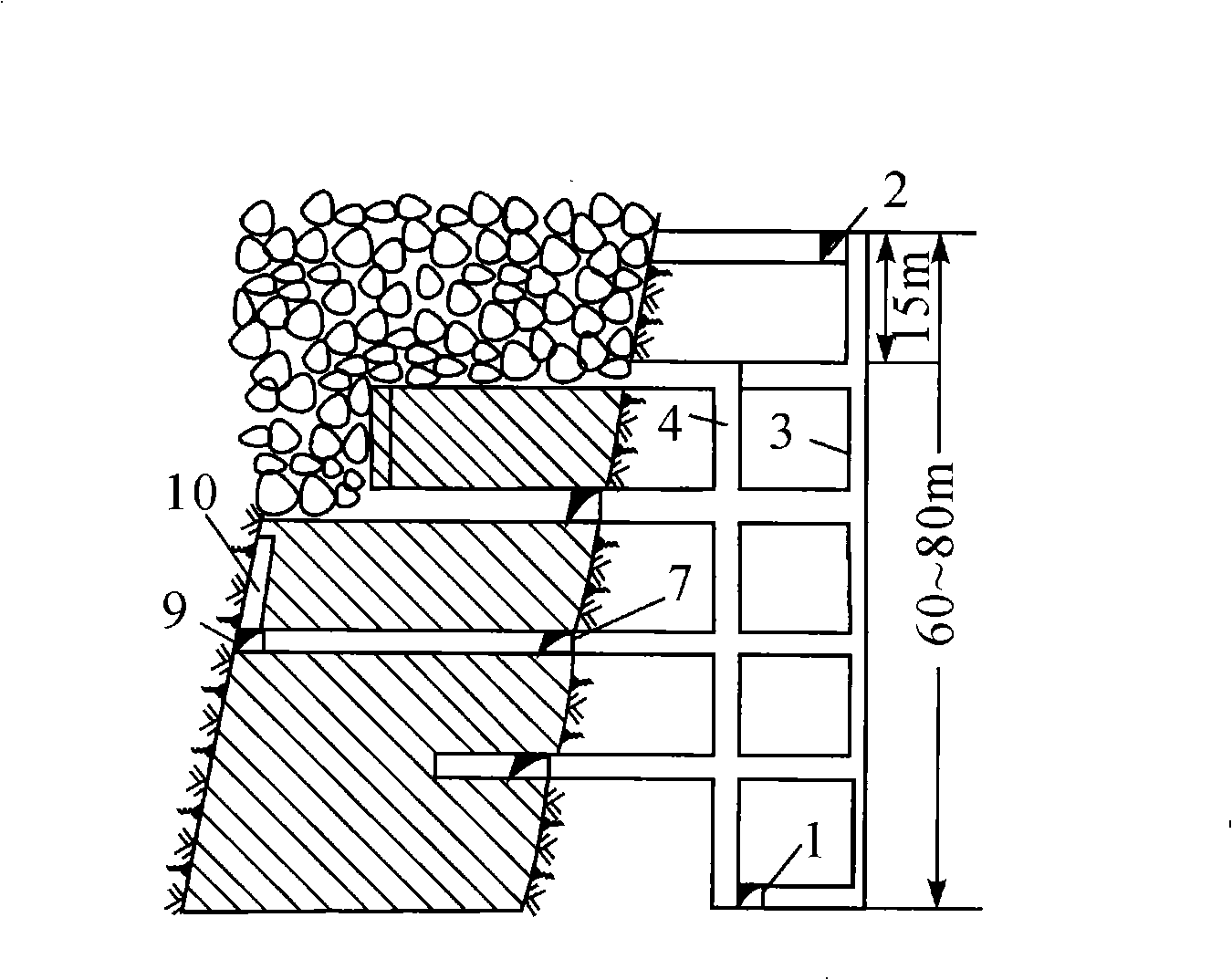

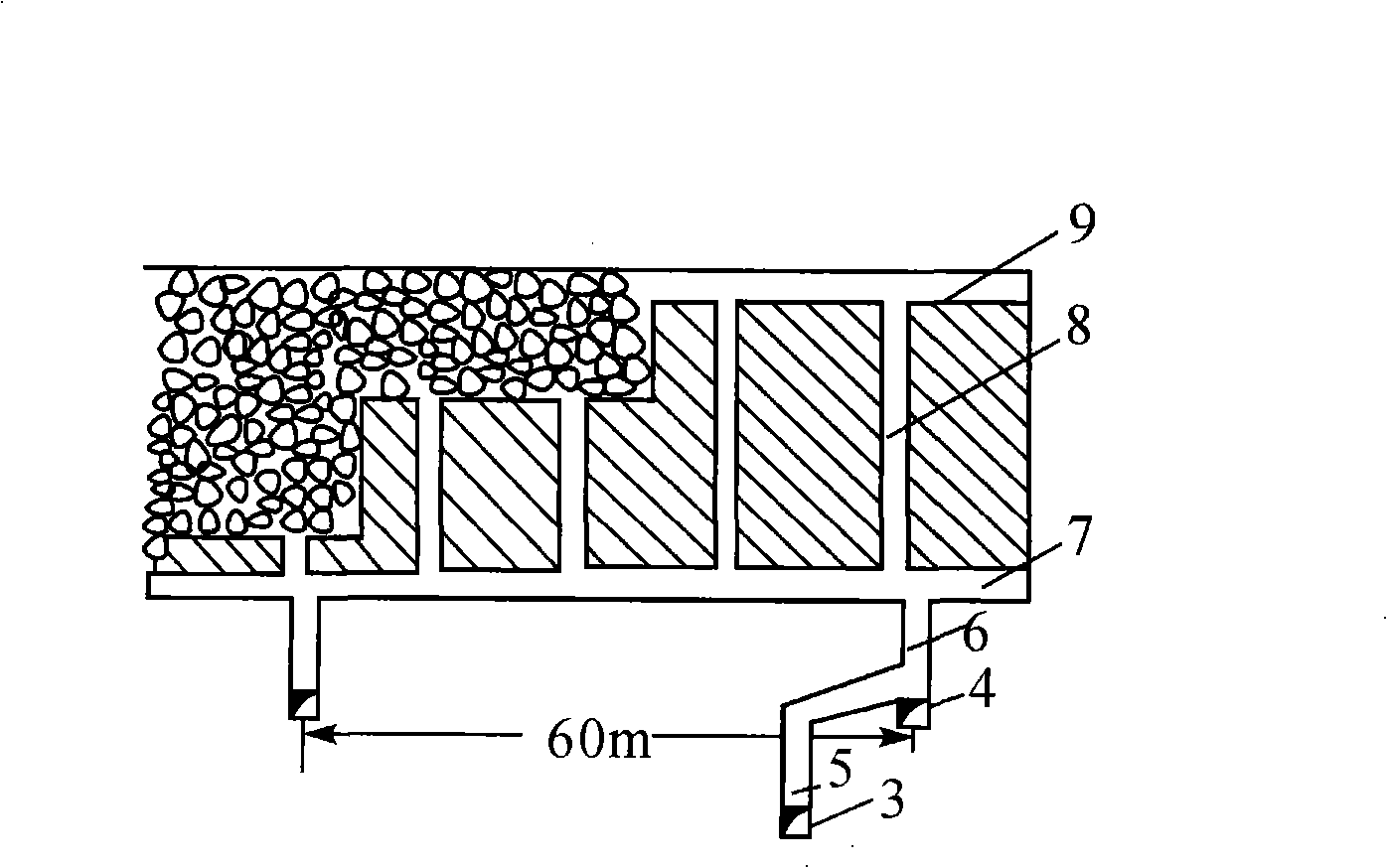

[0026] like Figure 4 , Figure 5 , Image 6 As shown, the pillarless sub-level caving mining method of direct shipment of ore includes the following steps:

[0027] 1) When the thickness of the ore body is 8-20m (meters), the ore blocks are arranged along the strike of the ore body ("ore block" refers to a single mining approach or 2-20 adjacent mining approaches, Mining areas with sequential mining and close production linkages); when the thickness of the ore body is greater than 20m, the ore blocks are arranged vertically to the ore body;

[0028] First excavate the vertical shaft or inclined shaft from the ground, and then transport the level roadway during the excavation stage through the vertical shaft or inclined shaft, and the transport level roadway communicates with the vertical shaft or inclined shaft; 0.5-1.0m thick downhill ore protection bottom layer), and excavate more than 2 (including 2) downhill 11 (also known as blind inclined shafts, Figure 5 11, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com