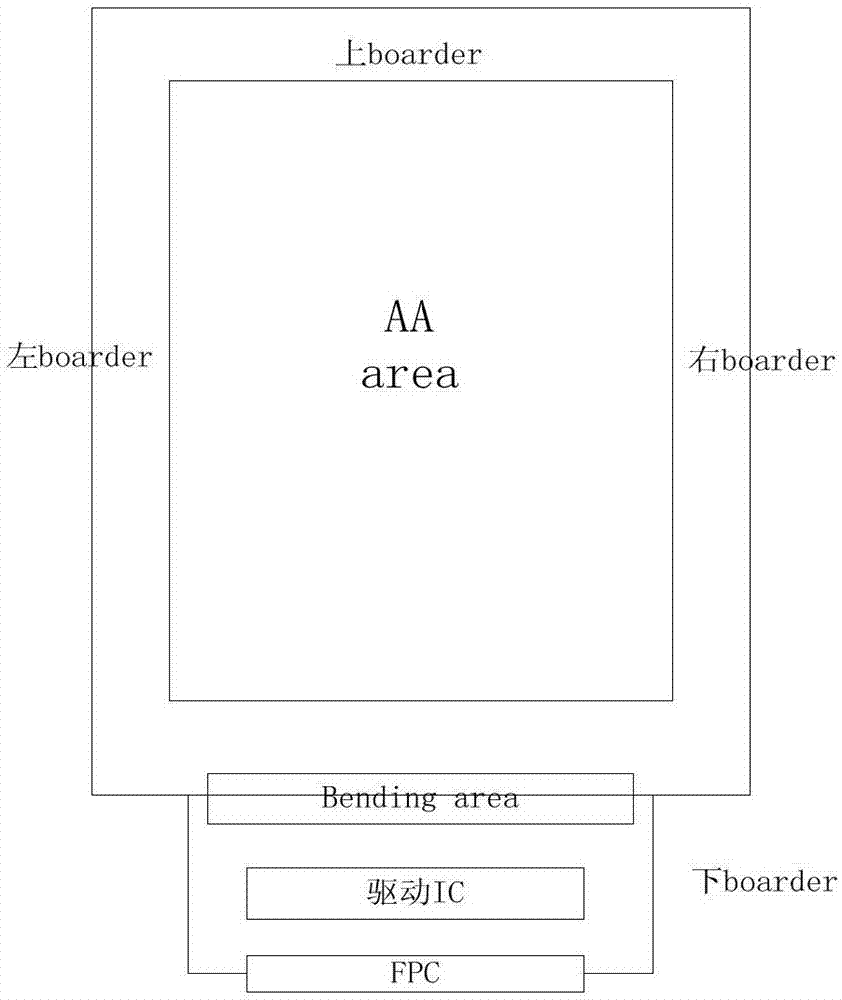

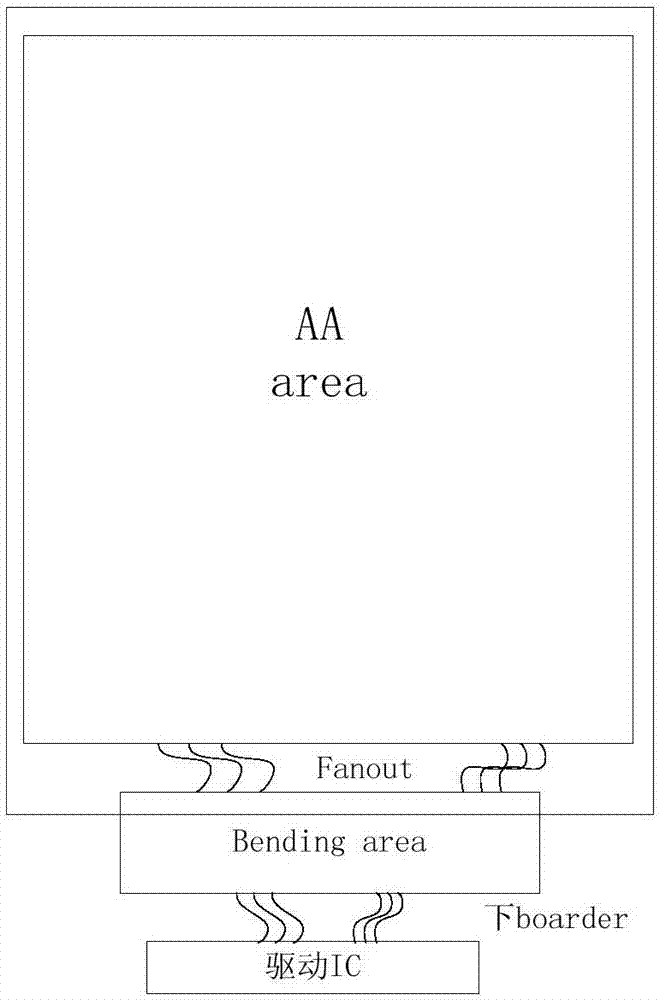

Bendable display panel and manufacturing method thereof

A manufacturing method and display panel technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as disconnection, difficulty in climbing, loss of electrical signals on display panels, etc., to improve quality, improve climbing ability, avoid The effect of electrical signal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

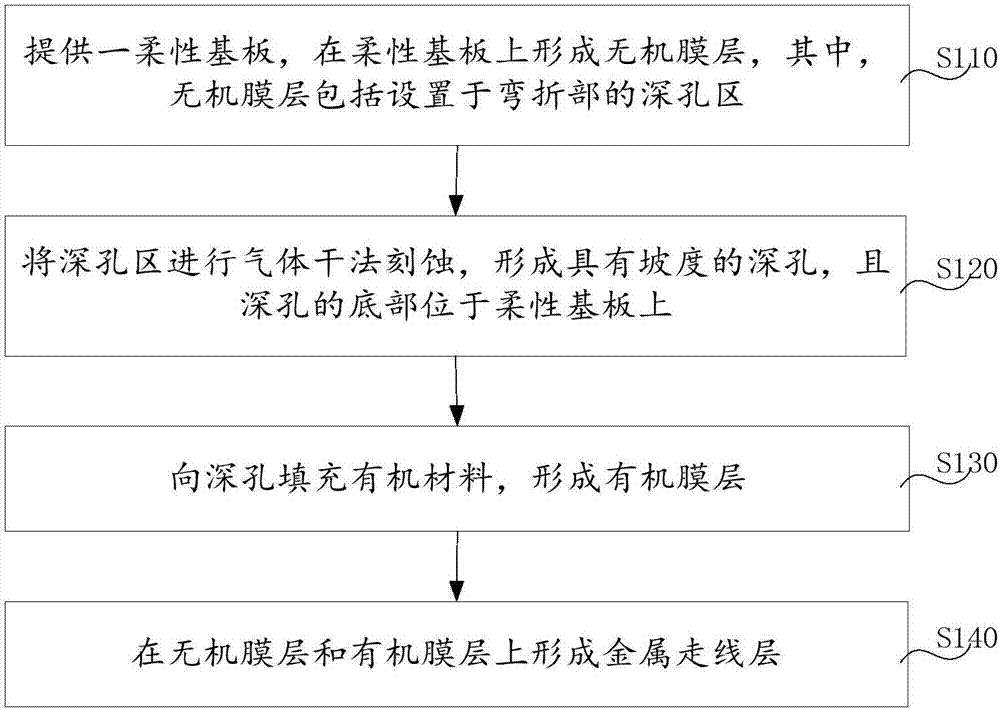

[0026] see image 3 , image 3 It is a schematic flowchart of the first embodiment of the manufacturing method of the bendable display panel of the present application. It should be noted that if there are substantially the same results, the method of the present application does not image 3 The flow sequence shown is limited. Such as image 3 As shown, the method includes the following steps:

[0027] Step S110: providing a flexible substrate, and forming an inorganic film layer on the flexible substrate, wherein the inorganic film layer includes a deep hole area disposed at the bending portion.

[0028] In this step, a bendable flexible substrate is provided first. Usually, the material of the flexible substrate adopts polymer materials such as polyimide plastic, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com