A flat famous green tea processing method

A processing method and famous technology, applied in the field of food processing, can solve the problems of failing to achieve quality improvement and technological breakthroughs, and product quality is difficult to compare with manual work, and achieve the effect of flat and smooth appearance and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] A kind of fresh leaf raw material used for the processing of a new type of flat famous high-quality green tea is: 50 kilograms of tea fresh leaves based on one bud and one leaf, and one bud and two leaves for the first time. The specific implementation method is as follows:

[0013] (1) Spread the fresh leaves on the stacked multi-layer spreading rack (ZL200820082983.8), and then place the rack in a booth with temperature and humidity control, and the vents are located under the wall, until the fresh leaves Moisture content 65%;

[0014] (2) Carry out the deenzyming process on the green leaves that have been processed by the step (1) on the roller degreening machine (the 6CST-40D type electric heating drum decapitation machine produced by Quzhou Lufeng Machinery Co., Ltd.), and the moisture content of the degreen leaves is 60-65%. , then directly go to the microwave greening machine (DXCWS-15 tea microwave greening machine produced by Yixing Dingxin Microwave Equipment ...

Embodiment 2

[0019] A kind of fresh leaf raw material used for the processing of a new type of flat famous high-quality green tea is: 50 kilograms of tea fresh leaves based on one bud and one leaf, and one bud and two leaves for the first time. The specific implementation method is as follows:

[0020] (1) Spread the fresh leaves on the stacked multi-layer spreading rack (ZL200820082983.8), and then place the rack in a booth with temperature and humidity control, and the vents are located under the wall, until the fresh leaves The moisture content is about 70%;

[0021] (2) Carry out the deenzyming process on the green leaves that have been processed by the step (1) on the roller degreening machine (the 6CST-40D type electric heating drum decapitation machine produced by Quzhou Lufeng Machinery Co., Ltd.), and the moisture content of the degreen leaves is 60-65%. , and then directly on the microwave greening machine (DXCWS-15 tea microwave greening machine produced by Yixing Dingxin Microw...

Embodiment 3

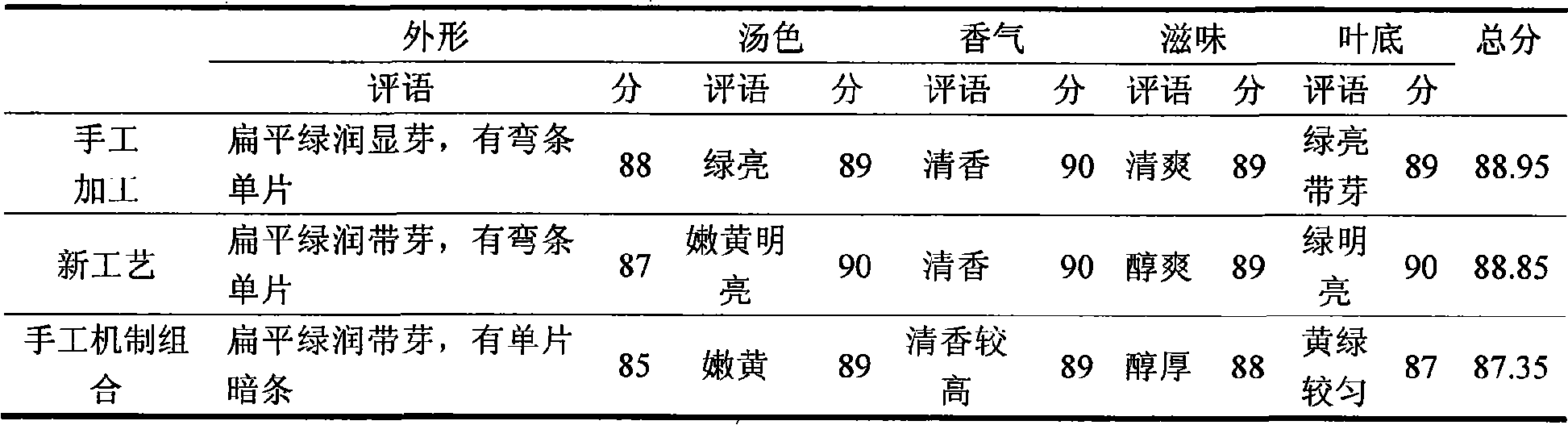

[0025] Example 3 Comparison of Sensory Evaluation of Flat Famous Green Tea Processed by Different Processes

[0026] The present invention compares the sensory evaluation of flat famous and high-quality green tea processed by different processes. It can be seen that the method of the present invention has little difference with the total score of the product processed by hand, and is obviously better than the product combined by manual mechanism. The results are shown in Table 1.

[0027] Table 1 Comparison of sensory evaluation of flat-shaped famous green tea processed by different processes

[0028]

[0029] Note: From the results of the sensory evaluation, it can be seen that the products processed by the new technology are not much different from those processed by hand, but they are significantly better than the products combined by manual mechanisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com