Full-automatic production device for assembling and cast-welding storage battery polar groups

A technology for production equipment and batteries, applied in the direction of electrode carriers/collectors, etc., can solve the problems of manual handling, flipping, and inability to realize fully automated production, and achieve the effects of avoiding damage, saving labor costs, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

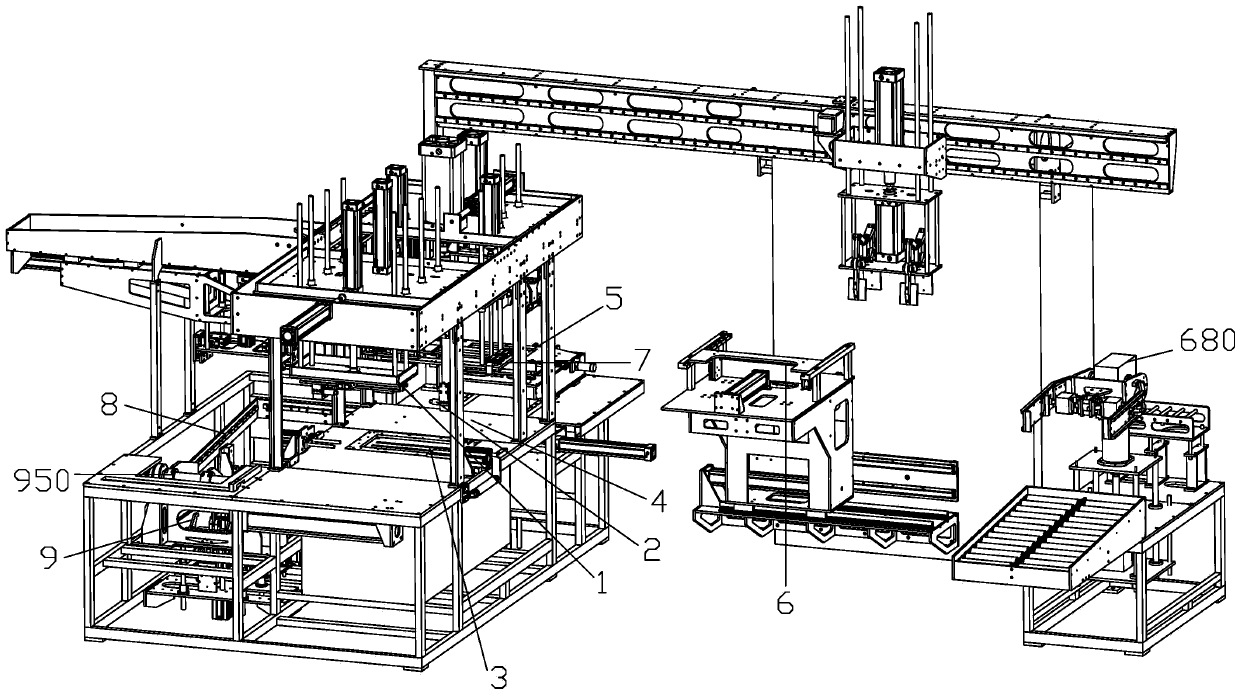

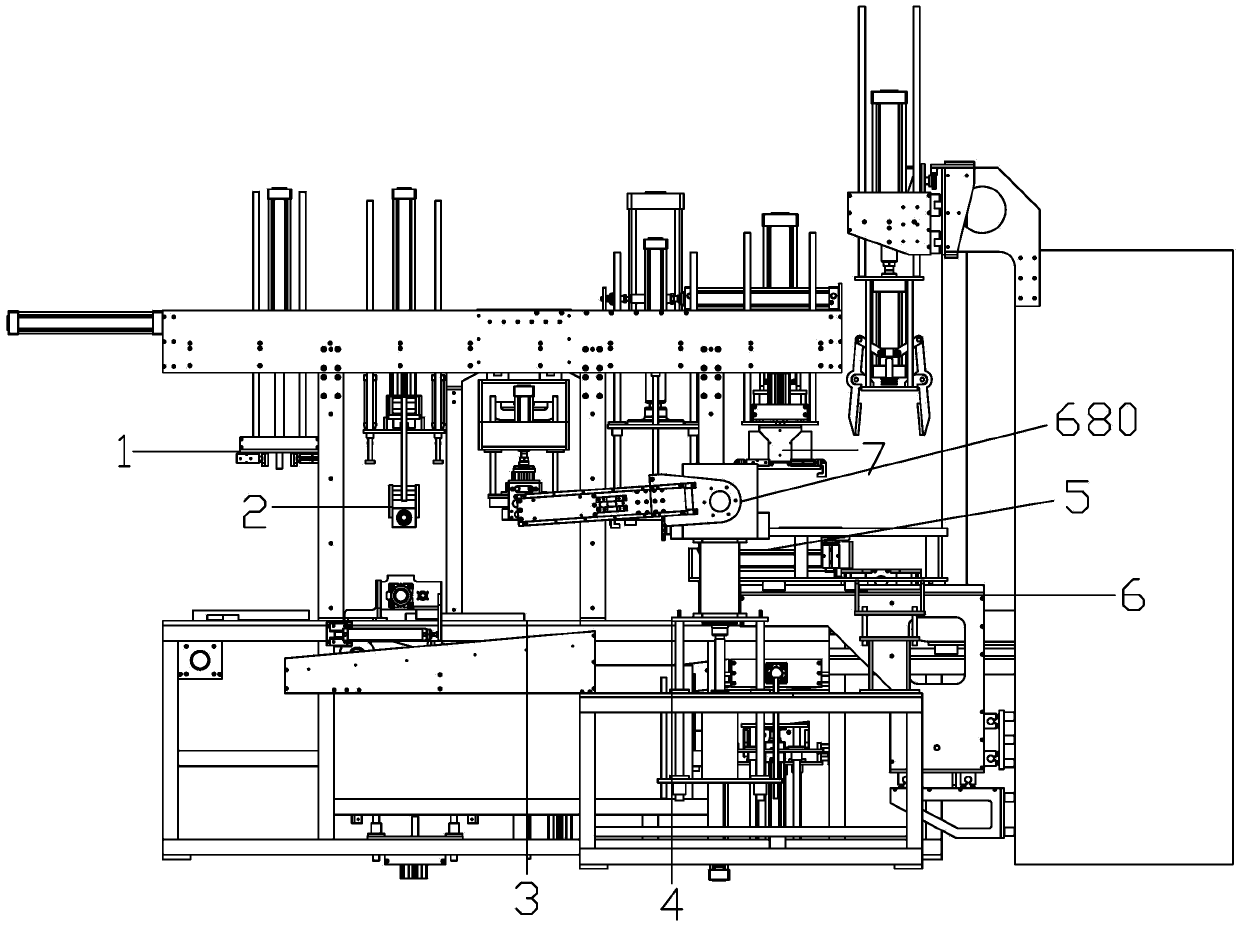

[0065] Such as Figure 1 to Figure 16 Shown is a schematic diagram of an embodiment of a battery electrode group assembly casting welding automatic production equipment provided by the present invention, which includes an electrode group fixture 0 and a tab shaping device 1 connected in sequence, a fixture turning device 2, and a tab cutting device 3. The pole group lower trough device 4, the tab kneading device 5 and the tab casting welding device 6.

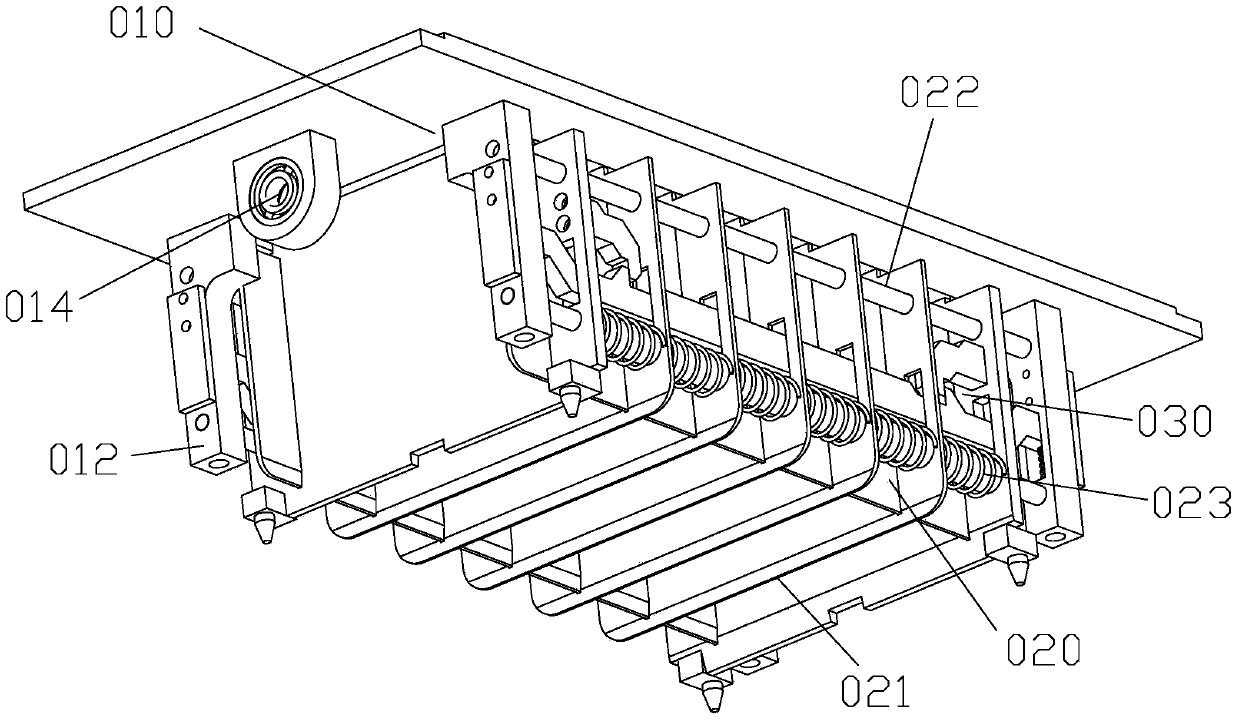

[0066] Such as Figure 3-5 As shown, the pole group fixture 0 includes a fixture frame 010, a clamping component 020, and a buckle component 030. The fixture frame 010 includes a rectangular bottom plate 011 with a rectangular opening, which is perpendicular to the rectangular bottom plate 011 and is arranged on four sides of the rectangular opening. The four support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com