Crankcase vertical-horizontal composite type multi-station combined machine tool

A combined machine tool and composite technology, applied in the field of machine tools, can solve the problems of reduced machining accuracy of workpieces, high labor intensity of workers, and accumulated positioning errors, and achieve the effects of reduced clamping and positioning times, high work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

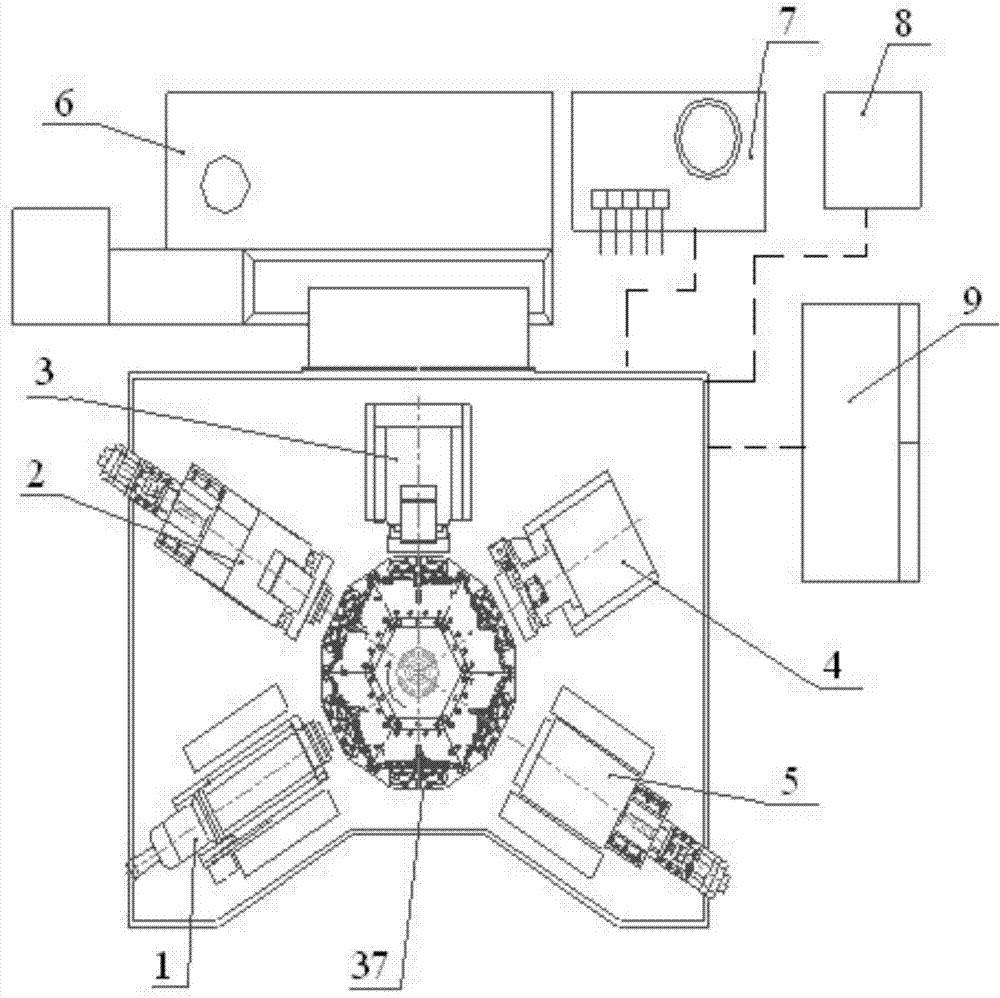

[0025] Such as Figure 1 to Figure 4 As shown, a crankcase vertical-horizontal compound multi-station combined machine tool, which includes: a base (10), a hydraulic rotary table (11) installed on the base (10), and a turntable expansion plate (12), and hydraulic pressure The cooling chip removal system (6), lubrication system (7), hydraulic press (8) and electrical system (9) connected to the rotary table (11);

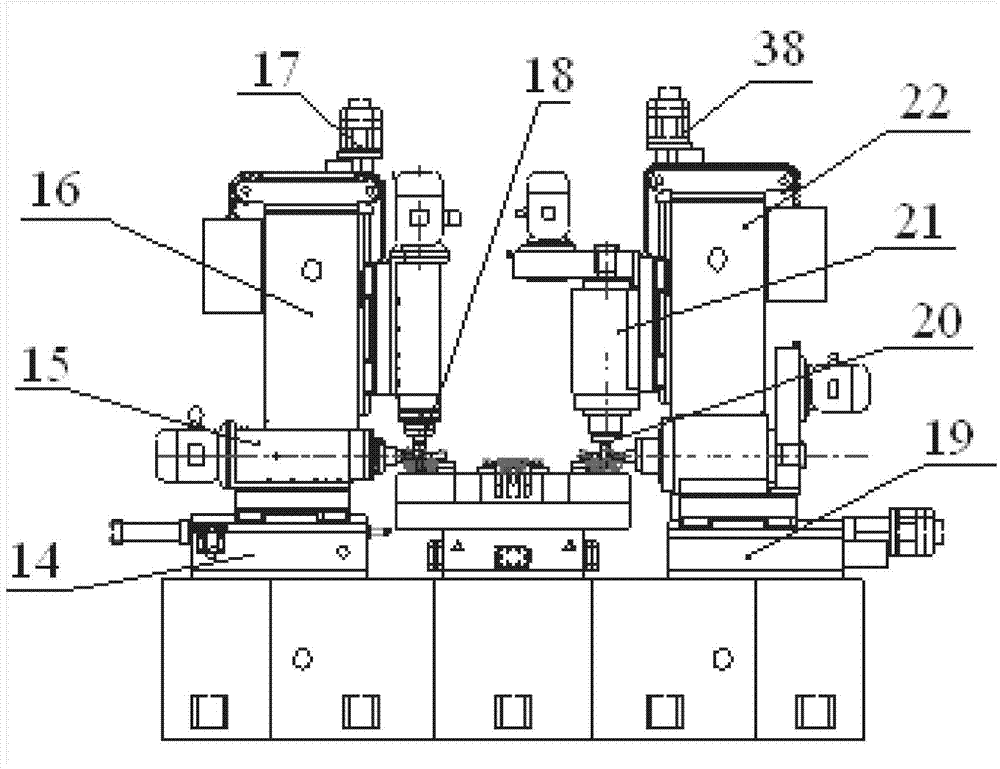

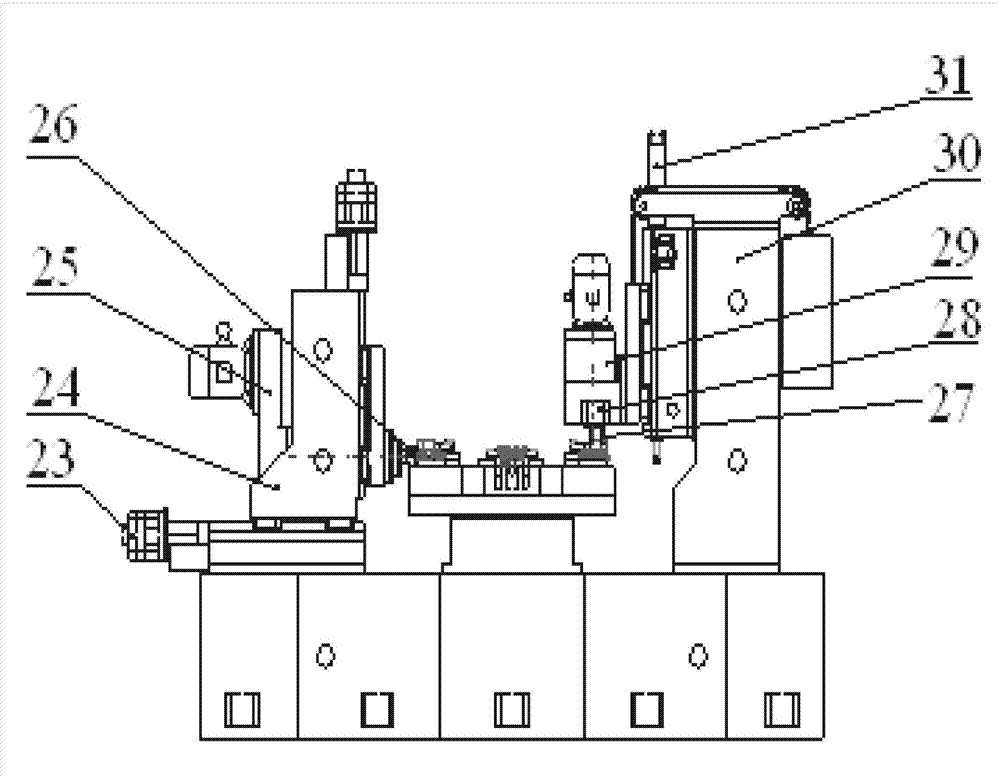

[0026] The rotary table (11) is provided with 6 processing units, the 6 processing units are respectively the first processing unit (37), vertical and horizontal compound semi-finish boring cylinder bore, shaft hole and rough countersinking Hole end face device (1), fine milling cylinder face device (2), vertical finish turning upper supporting surface device (3), vertical drilling upper supporting surface 3 holes and chamfering device (4), fine boring cylinder bore, shaft The hole and the end surface device (5) of fine spot facing shaft hole, and the hydraulic tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com