Prediction method of service life of drilling tool with CFRP(carbon fiber reinforced plastic) and titanium alloy laminated structure

A technology of laminated structure and drilling tool, which is applied in the field of laminated assembly of carbon fiber composite materials and titanium alloys, can solve the problems of not being able to comprehensively reflect the defects of composite materials, cutter surface wear, and no prediction method for drill bit life, achieving high accuracy , Reduce the scrap rate of parts, and the effect of large drilling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

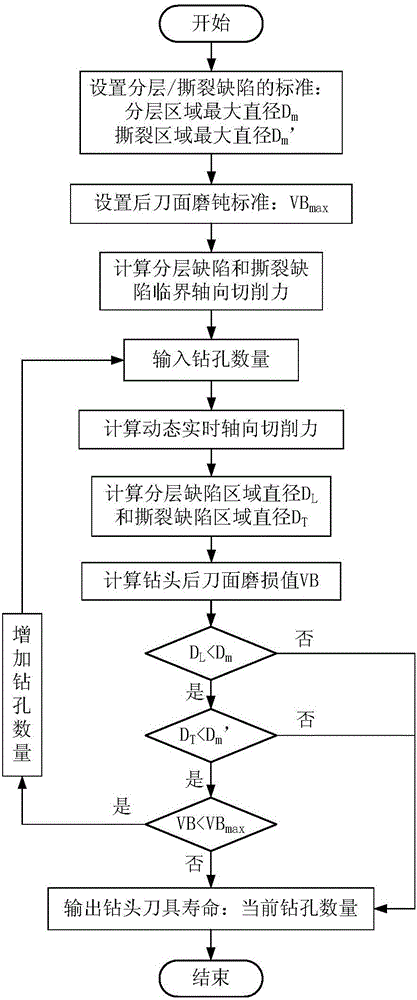

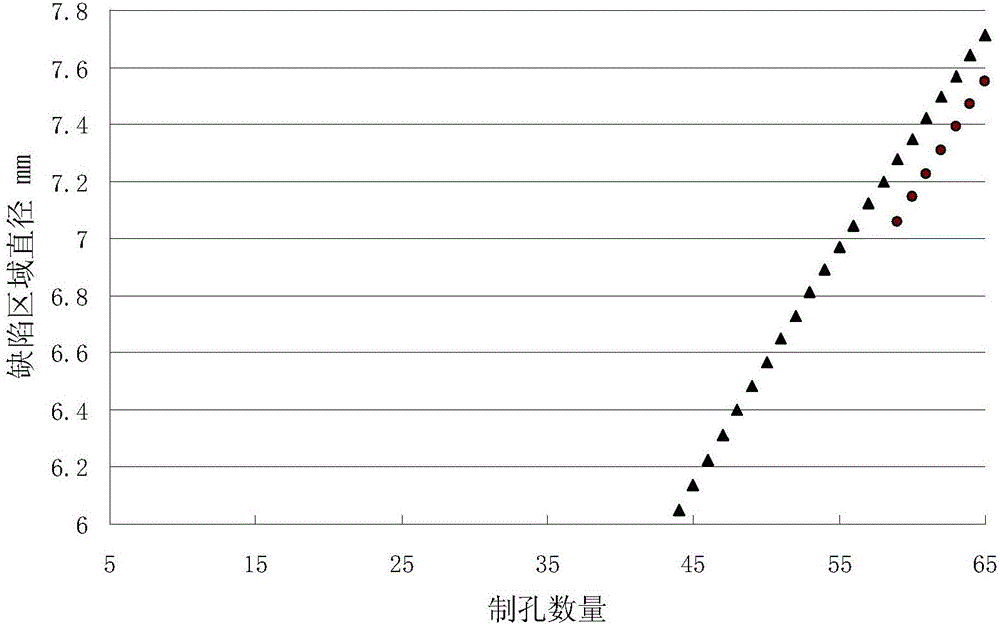

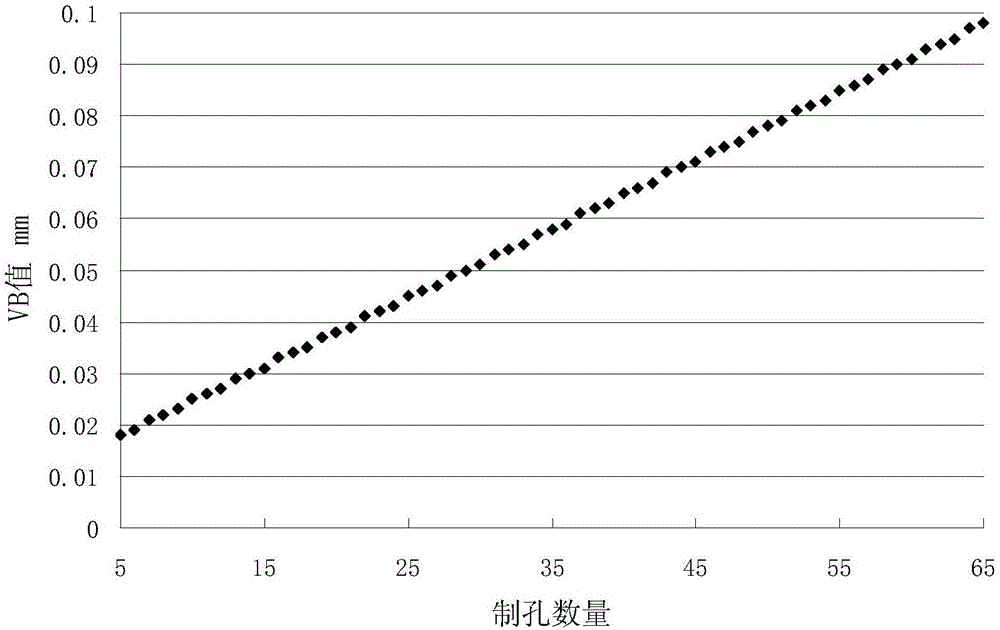

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0038] Taking the drilling process of T300 carbon fiber composite material and TC6 titanium alloy laminated structure as an example, the drilling conditions and defect requirements of the laminated structure are as follows:

[0039] (1) Geometric parameters of drill bit structure: diameter is 6mm, helix angle is 25 degrees, outer edge relief angle is 10 degrees, and apex angle is 140 degrees;

[0040] (2) The tool material is K6UF (tungsten carbide);

[0041] (3) Drilling process parameters: cutting speed is 30m / min, feed rate is 0.03mm / r;

[0042] (4) Requirements for drilling defects: After drilling, the composite material is not allowed to have delamination defects, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com