Fan assembling machine

A technology for fan groups and components, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing work efficiency, a lot of manpower, and increasing costs, and achieve the effects of convenient operation, stable work performance, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

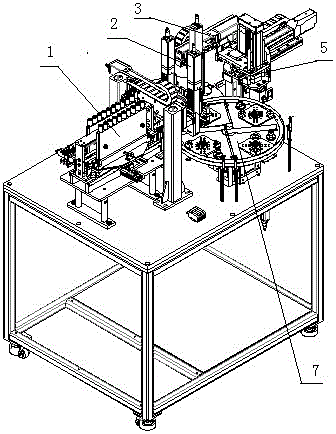

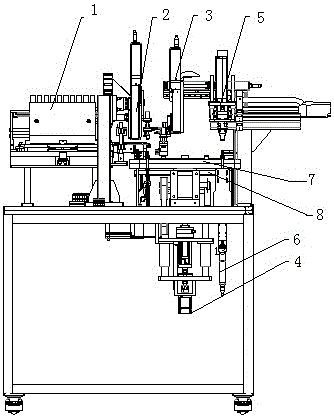

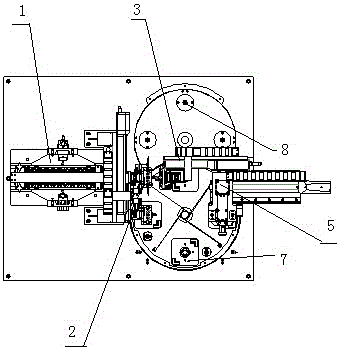

[0018] Below in conjunction with accompanying drawing, the present invention is further described:

[0019]As shown in the drawings, a fan assembly machine is equipped with a frame, which is characterized in that the frame is equipped with a bearing feeding mechanism 1, a bearing transport mechanism 2, a blade rotor pressing mechanism 3, a lower bearing and a clamping mechanism. The three-piece pressing mechanism 4 of the spring and the backing ring, the finished product unloading mechanism 5, the image detection mechanism 6 and two rotary disks are composed. The sensor 11 and the material cutting cylinder 12 are composed, and the bearing pushing assembly 10 is composed of a linear sliding assembly 13, a material cutting jig 14, a rodless cylinder 15 and a guide rod 16, and the rodless cylinder 15 is controlled by a three-position mid-release solenoid valve to drive the cutting machine. The material fixture 14 pushes the bearing to move forward, and the bearing moves forward b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com