Triangular glue adhering machine

A technology of apex rubber and laminating machine, which is applied to tires, other household appliances, household appliances, etc. It can solve the problems of compounding giant tire bead rings and apex rubber, compound width and weight increase, etc., to achieve good adaptability, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

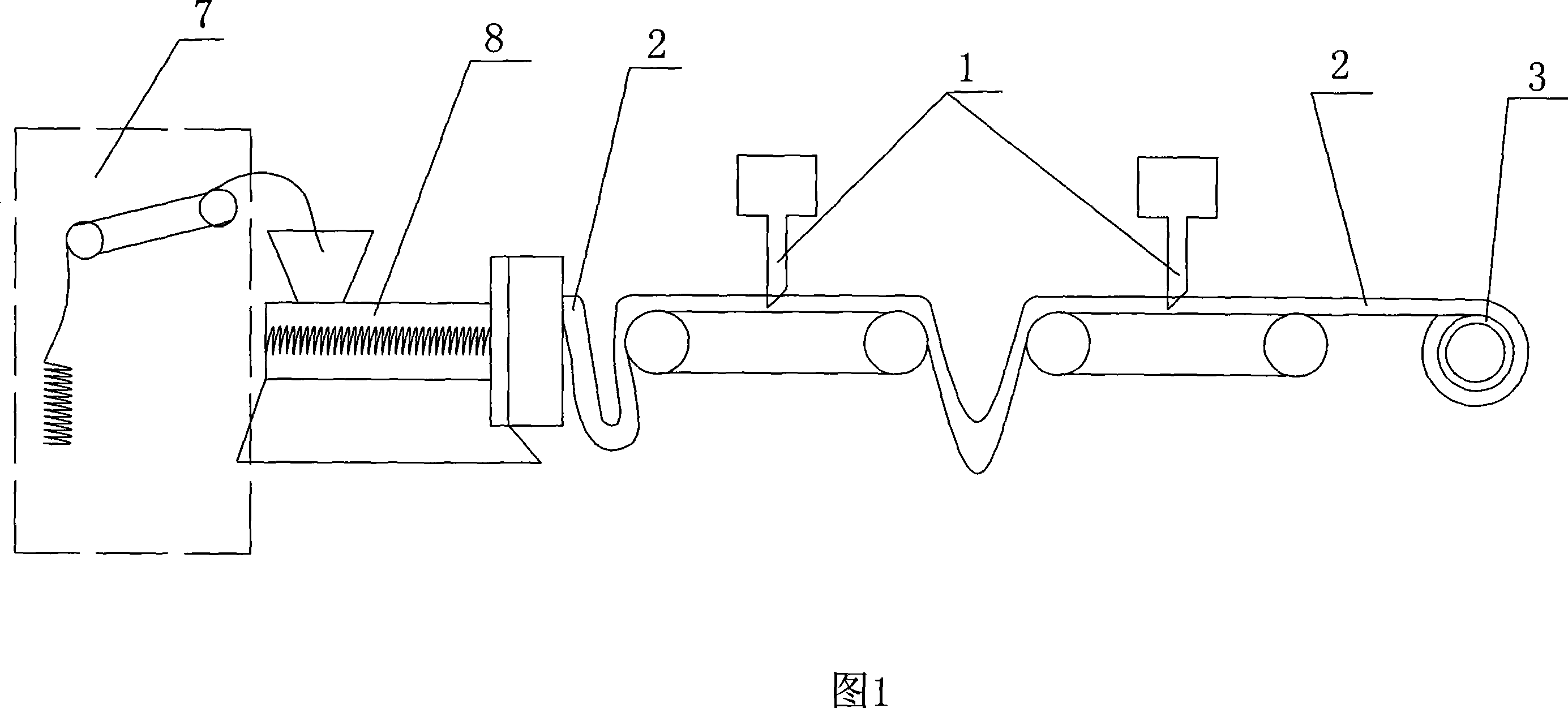

[0026] In the embodiment shown in Figure 1, the apex laminating machine of the present invention consists of a glue supply device, an extruder, a rubber material conveying device, a rubber material fixed-length cutting device, and a winding machine that rotates the traveler 3 in a vertical plane. Laminating devices etc. form a production line in turn.

[0027] The glue supply device is the glue supply machine 7, which is the first process equipment of the present invention. The glue supply machine 7 is actually an obliquely installed conveyor belt, and the glue placed on one side and folded and stacked is conveyed by the conveyor belt. The extruder is a cold-feed extruder 8, and the cold-feed extruder 8 is arranged next to the glue feeder 7 as the second process equipment of the present invention, and there are three sections inside the cold-feed extruder 8. Heating function, the extrusion cavity of the cold feed extruder 8 is a spiral extruding rod lying horizontally, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com