Coaxial image system applied to LED laser cutting device

A technology of laser cutting and image system, applied in the field of coaxial image system and optical image system, to achieve the effect of unique design, excellent function and broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

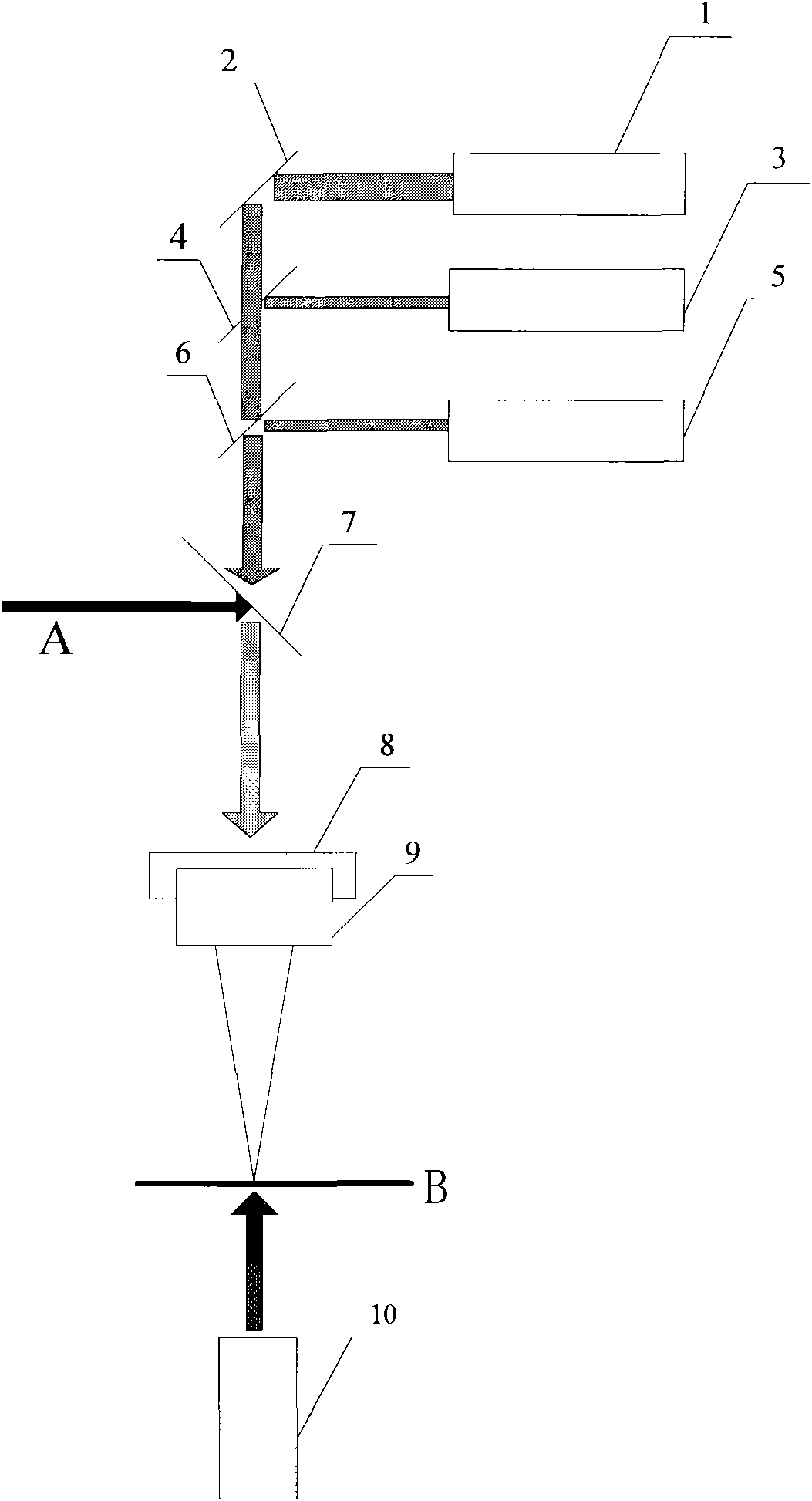

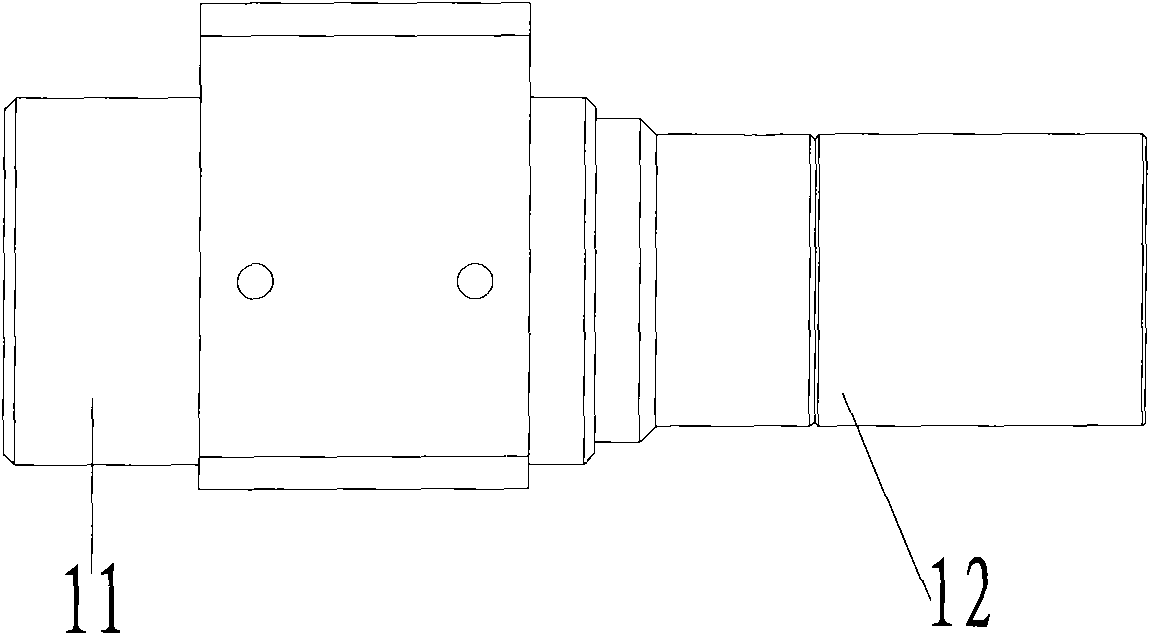

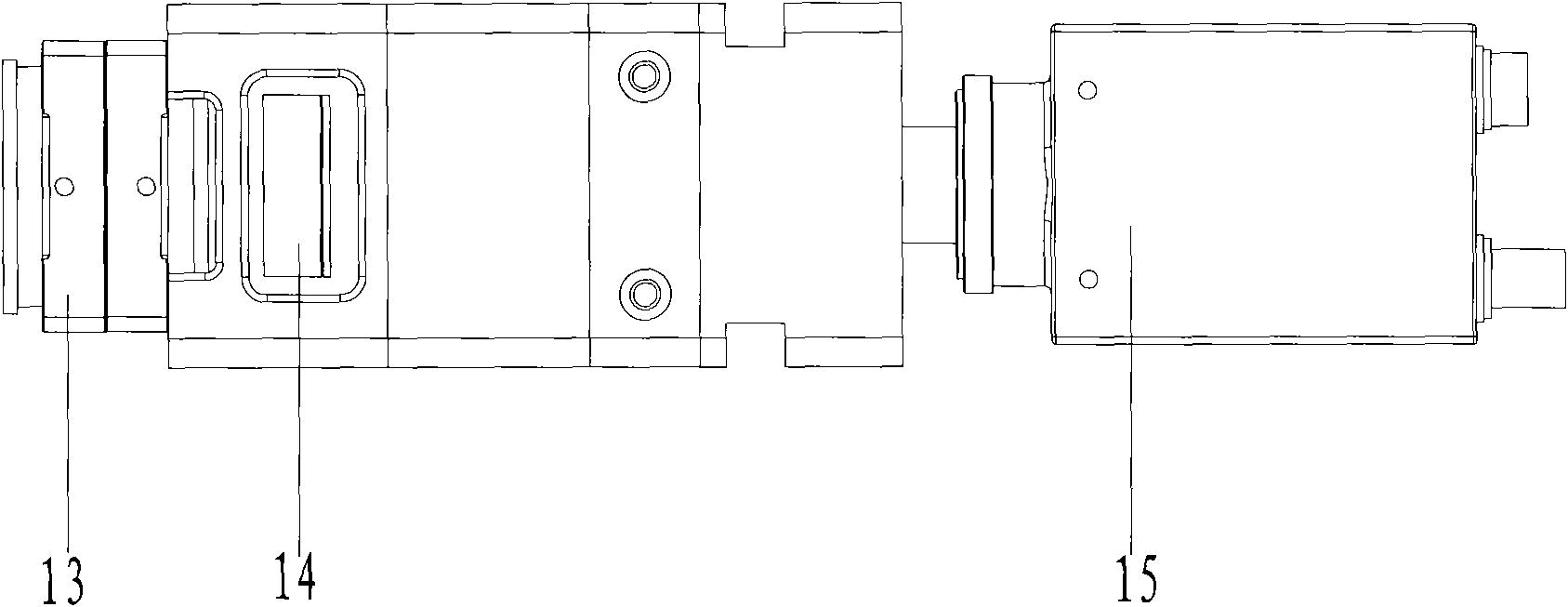

[0025] like figure 1 As shown, the coaxial image system applied to LED laser cutting equipment includes coaxial LED point light source module 1, 45-degree full reflection mirror 2, wide-angle CCD module 3, first 45-degree beam splitter 4, small field of view and high magnification Upper CCD module 5, second 45-degree beam splitter 6, wavelength selective mirror 7, LED ring light source 8, focusing mirror 9, small field of view and high magnification lower CCD module 10, coaxial LED point light source module 1, wide-angle CCD module Group 3 and the upper CCD module 5 with small field of view and high magnification are arranged side by side from top to bottom, the wavelength selective mirror 7 is installed between the upper CCD module 5 and the focusing mirror 9, and the LED ring light source 8 is closely attached to the focusing mirror 9 On the top, the focusing lens 9 is facing the workpiece B, and the CCD module 10 with a small field of view and high magnification is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com