Cutting method of wafer grade white-light LED chip

A technology of LED chip and cutting method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of chip fluorescent glue damage, substrate cracking, affecting product yield and reliability, etc., to improve production yield, avoid broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments.

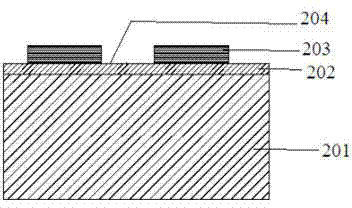

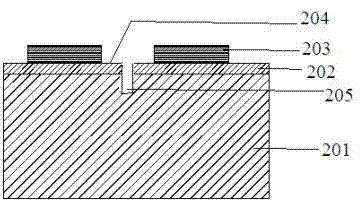

[0014] As shown in FIG. 2, a cutting method of a wafer-level white light LED chip includes preparing a GaN wafer with a vertical structure on a silicon substrate 201, such as Figure 2a , 202 in the figure is a conductive reflective composite metal layer, and the GaN LED 203 is separated by the scribe line 204; the 355nm ultraviolet laser emitted by the laser is focused to the middle position of the upper surface groove scribe line 204 of the silicon substrate 201, forming a 30 ±5 μm, groove 205 with a width of 10±2 μm, such as Figure 2b ; Coating a 30 μm thick fluorescent adhesive layer 206 on the wafer, making it distributed on the entire chip surface, and then baking and curing, as Figure 2c ; Mechanically grind and thin the silicon substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com