Method for preparing high-purity mesophase pitch and prepared high-purity mesophase pitch

A mesophase asphalt and high-purity technology, which is applied in the direction of chemical processing of tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of complex preparation process, demanding equipment and materials, difficulty in separation and recycling, etc., to achieve purity and High coking value, easy control and operation, low ash and softening point effect

Active Publication Date: 2013-01-30

济宁辰星碳素有限公司

View PDF2 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this way, the mesophase pitch prepared by using coal tar pitch and petroleum pitch inevitably has some disadvantages, such as complicated preparation process, high preparation cost, and low performance of the prepared carbon fiber.

In addition, the model aromatic hydrocarbon compound - naphthalene is used as a raw material to prepare mesophase pitch, and the composition, structure and properties of the product can be controlled by adjusting the polymerization reaction conditions, but the catalysts used - hydrogen fluoride and boron trifluoride are relatively corrosive , the requirements for equipment materials are harsh, and there are problems such as operation protection and environmental pollution in high temperature and high pressure polymerization reactions in airtight containers (Mochida I, Shimizu K, Korai Y. Preparation of mesophase pitch from aromatic hydrocarbons by the aid of HF / BF3[J]. Carbon, 1990, 28: 311-319), difficult to industrial scale production

The publication number is CN101525543A Chinese patent application also provides a kind of preparation method of mesophase pitch, but the shape and structure of the mesophase pitch produced by it are not ideal, there are unmelted small spheres on the surface

The synthesis process of mesophase pitch with low softening point and good rheological properties has been reported by using mild Lewis acid-aluminum trichloride as a catalyst from aromatic compounds such as quinoline or isoquinoline derivatives or ethylene tar (Mochida I, Shimizu K, Korai Y, Ku C H, et al. Chemistry of synthesis, structure, preparation and application of aromatic-derived mesophase pitch[J]. Carbon, 2000, 38: 843-852), but aluminum trichloride The use of the same reaction system has the disadvantage of being difficult to separate and recycle. The catalyst is not completely removed, resulting in low product purity and high ash content, which directly affects the spinnability of the mesophase pitch and the final carbon fiber performance, which has seriously troubled domestic and foreign manufacturers. researchers, leading to the failure of the preparation process to promote

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Login to View More

Abstract

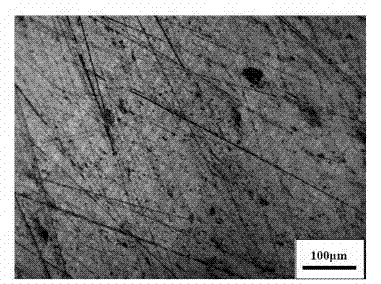

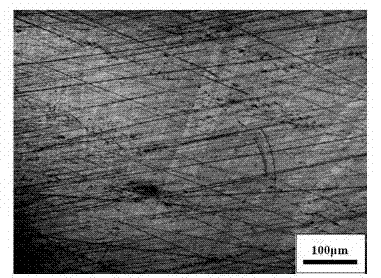

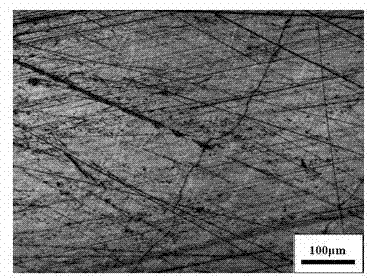

The invention relates to a method for preparing high-purity mesophase pitch and prepared high-purity mesophase pitch. According to the technical scheme, the method for preparing the high-purity mesophase pitch comprises the following steps of: reacting refined naphthalene taken as a raw material with anhydrous aluminum trioxide taken as a catalyst in oil bath at 100 to 220 DEG C and a stirring rate of 200 to 600 r / min for 5 to 20 hours; removing the catalyst to obtain naphthalene pitch; and polymerizing the naphthalene pitch at 350 to 480 DEG C and a stirring rate of 400 to 1,000 r / min for 3 to 24 hours to obtain the high-purity mesophase pitch. The preparation process is simple, production cost is relatively low, and a mesophase forming process and a mesophase composition structure are easy to design and control; the prepared mesophase pitch is high in purity (ash content is only 50 to 150 ppm), low in softening point (260 to 280 DEG C), and high in mesophase content (100 volume percent), and has a wide-area streamlined optical anisotropic structure, the rheological property after fusion is excellent, spinnability is good, and the mesophase pitch is suitable to be used as a quality raw material of novel carbon materials such as high-performance pitch-based carbon fibers.

Description

technical field [0001] The invention relates to the field of carbon industry, in particular to a high-purity mesophase pitch, in particular to a method for preparing high-purity mesophase pitch and the prepared high-purity mesophase pitch. Background technique [0002] In the 19th century, the technology of refining coke from coal has been greatly developed. The main difference between the obtained coke and other coke is its different graphitization ability at high temperature. Brooks and Taylor examined coal tar during melting with a polarizing microscope and found that there is an anisotropic streamlined and mosaic structure formed, which is formed, grown and melted and deformed by an anisotropic globule formed later. It was later found that the same phenomenon occurs when anisotropic, graphitizable carbon materials are prepared from fusible organic compounds. Brooks and Taylor called this intermediate phase state in the preparation of graphitizable carbon materials "m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10C3/02

Inventor 李轩科闫桂林车忠敏

Owner 济宁辰星碳素有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com