Phase-change material microcapsule and preparation method thereof

A technology of phase change materials and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of increasing process steps and complicated preparation process, and achieve simple process, convenient operation and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

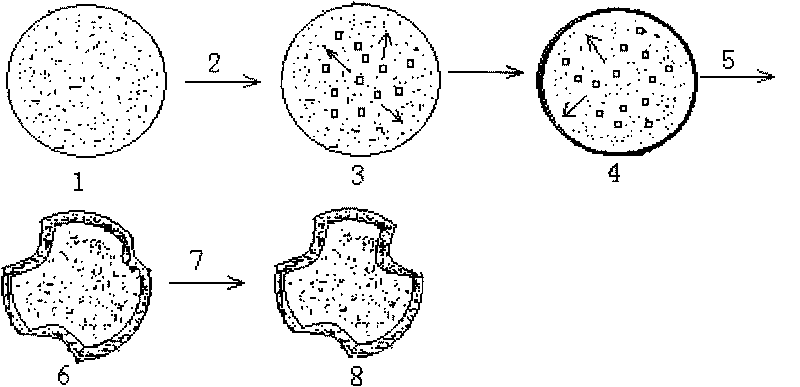

Method used

Image

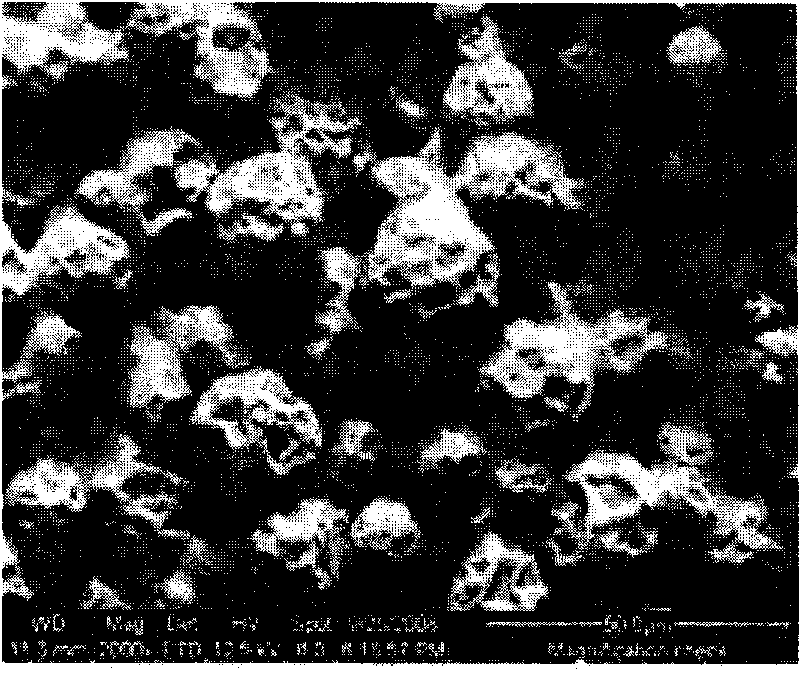

Examples

Embodiment 1

[0071] Microcapsule mass percentage composition design is:

[0072] Oil phase 190g, wherein radical polymerizable monomers include methyl acrylate (MA) 28g, n-butyl methacrylate 10g, styrene (St) 15g, crosslinking agent glycerol trimethacrylate 18g, phase change material 117 g of 1-bromooctadecane (Broct) and 2 g of the initiator azobisisoheptanonitrile.

[0073] Water phase 1000g, wherein deionized water (abbreviated as water) 970g, emulsifier sodium lauryl sulfate 10g, co-emulsifier 1-tetradecyl alcohol and 10g and stabilizer polyethylene glycol (number average molecular weight 600) 10g.

[0074] The mass percentage of the oil phase in the mixed liquid is 16%.

[0075] The preparation method of the microcapsules is as follows: First, at a temperature I of 40° C. and a stirring speed I of 600 rpm, the mixture of the free radical polymerization monomer, crosslinking agent, organic phase change material and initiator in the mass percentage is stirred evenly , to make an oil p...

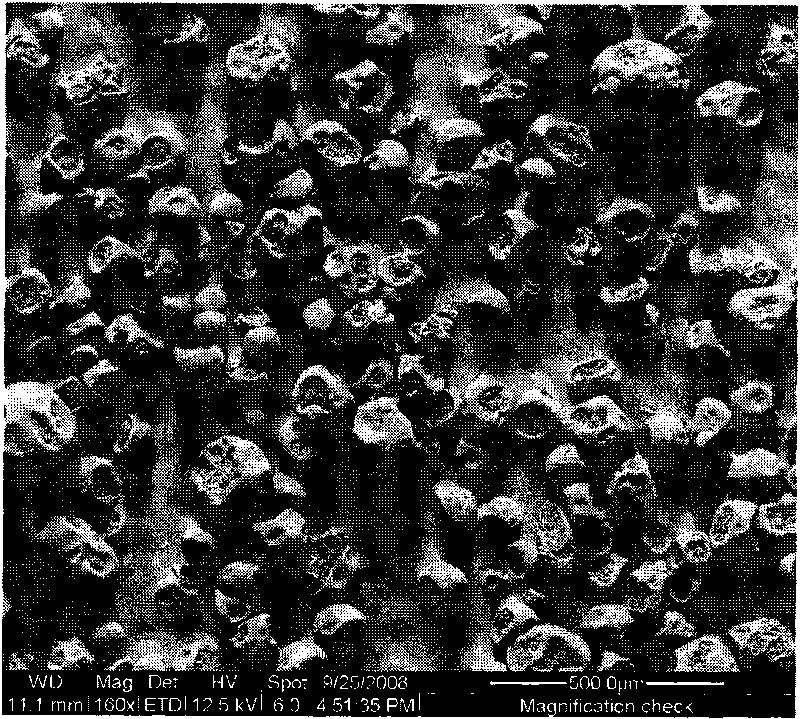

Embodiment 2

[0078] The mass percent of microcapsules consists of:

[0079] Oil phase 600g, wherein radical polymerization monomer comprises methylstyrene (MSt) 265g, crosslinking agent divinylbenzene (DVB) 28g, phase change material 1-bromoeicosane (Brei) 300g and free polymerization initiator Azobisisobutyronitrile (AIBN) 7g.

[0080] Water phase 2400g, wherein water 2352g, emulsifier sorbitol oleate (Span 80) 24g, stabilizer polyvinyl alcohol (polymerization degree 1750, hydrolysis degree 98%) 24g.

[0081] The mass percentage of the oil phase in the mixed liquid is 20%.

[0082] The preparation method of the microcapsules is as follows: First, at a temperature I of 60° C. and a stirring speed I of 800 rpm, the mixture of the free radical polymerization monomer, crosslinking agent, organic phase change material and initiator in the mass percentage is stirred evenly , to make an oil phase; at a temperature I of 60°C and a stirring speed I of 800rpm, the mass percent emulsifier, co-emul...

Embodiment 3~5

[0085] Using the same process conditions as in Example 2, only changing the mass percentage of 1-bromoeicosane and polymerized monomers and crosslinking agents, phase change material microcapsules with different 1-bromoeicosane contents were obtained. As shown in Table 1. The mass percent compositions of embodiment 3-5 microcapsules are respectively:

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Endothermic temperature | aaaaa | aaaaa |

| Exothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com