Method for detecting content of active silicon in bauxite

A determination method and technology for bauxite, which can be applied in the direction of removing certain components for weighing, preparation of test samples, etc., and can solve the problem of no content determination method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

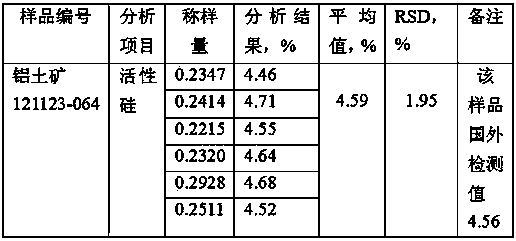

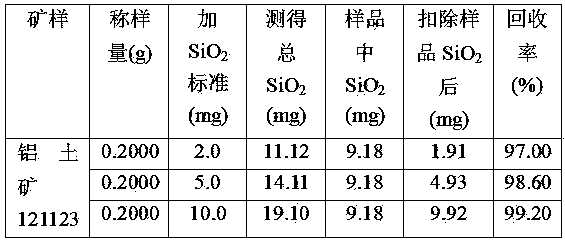

Examples

Embodiment 1

[0029] Embodiment 1, a kind of content assay method of active silicon in bauxite, its steps are as follows:

[0030] (1) Accurately weigh 0.2g of bauxite sample into a microwave digestion tank, add 20mL of AR grade sodium hydroxide solution with a mass concentration of 80g / L, and microwave at 0-145°C for 25min;

[0031] (2) Take it off after cooling, transfer it into a beaker, filter it with slow filter paper, wash it with AR grade sodium hydroxide solution with a mass concentration of 8g / L for 4 times, and keep the filtrate A and the insoluble residue respectively;

[0032] (3) Move the insoluble residue into the original beaker, add 18mL of hydrochloric acid solution, and place it on the electric heating plate for leaching; the hydrochloric acid solution is AR grade, and the hydrochloric acid solution is formed by mixing concentrated hydrochloric acid and water with a volume ratio of 1:1.5;

[0033] (4) Remove and filter, wash 4 times with hydrochloric acid solution, and kee...

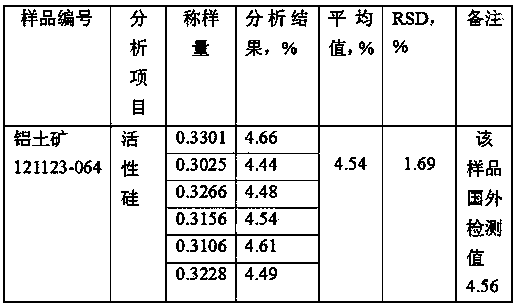

Embodiment 2

[0039] Embodiment 2, a kind of content determination method of active silicon in bauxite, its steps are as follows:

[0040] (1) Accurately weigh 0.5g of bauxite sample into a microwave digestion tank, add 25mL of AR grade sodium hydroxide solution with a mass concentration of 120g / L, and microwave at 0-145°C for 40min;

[0041] (2) Take it off after cooling, transfer it into a beaker, filter it with slow filter paper, wash it with AR grade sodium hydroxide solution with a mass concentration of 12g / L for 6 times, and keep the filtrate A and the insoluble residue respectively;

[0042] (3) Move the insoluble residue into the original beaker, add 25 mL of hydrochloric acid solution, and place it on a heating plate for leaching; the hydrochloric acid solution is AR grade, and the hydrochloric acid solution is formed by mixing concentrated hydrochloric acid and water with a volume ratio of 1: 2.5;

[0043] (4) Take off and filter, wash 6 times with hydrochloric acid solution, get ...

Embodiment 3

[0049] Embodiment 3, a kind of content determination method of active silicon in bauxite, its steps are as follows:

[0050] (1) Accurately weigh 0.2-0.5g of bauxite sample into a microwave digestion tank, add 20-25mL of AR grade sodium hydroxide solution with a mass concentration of 100g / L, and microwave at 0-145°C for 30min;

[0051] (2) Take it off after cooling, transfer it into a 250mL beaker, filter it with slow filter paper, wash it with AR grade sodium hydroxide solution with a mass concentration of 10g / L for 4-6 times, and keep the filtrate A and the insoluble residue respectively;

[0052] (3) Move the insoluble residue into the original beaker, add 20mL of hydrochloric acid solution, and place it on the electric heating plate for leaching; the hydrochloric acid solution is of AR grade, and the volume ratio concentration is 1+2;

[0053] (4) Take off the filter, wash with hydrochloric acid solution for 4-6 times, and keep the filtrate B; the hydrochloric acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com