Cemented carbide having nearly spherical WC grains and preparing method thereof

A cemented carbide and near-spherical technology, which is applied in the field of cemented carbide with nearly spherical WC grains and its preparation, can solve the problems of troublesome preparation methods, reduced alloy properties, and cubic phase enrichment, etc. The effect of chipping, reducing stress concentration, and low ball milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

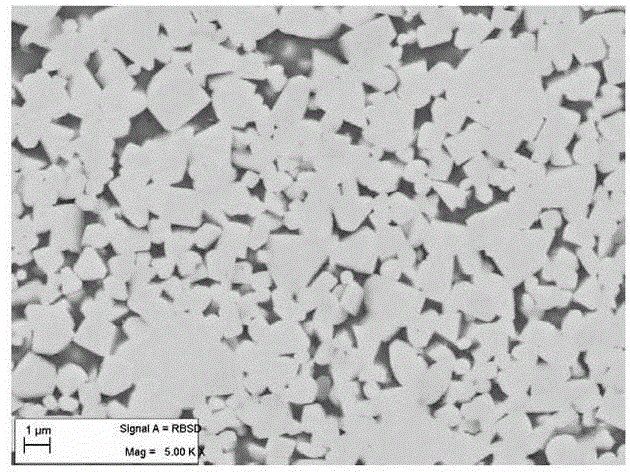

[0030] An example of the present invention figure 1 The cemented carbide with nearly spherical WC grains shown is composed of Co, cubic TaC and WC, wherein the content of Co is 12.5wt% (if not otherwise specified, all refer to the mass fraction, the same below ), the content of cubic TaC is 2.45wt%, the balance is WC, the C / W ratio of the cemented carbide is 0.824; the WC grains in the cemented carbide are nearly spherical, and the sphericity of the WC grains is 0.79 .

[0031] In this embodiment, the FSSS grain size of the WC raw material is 2.40 μm, and the cemented carbide is a uniform cemented carbide.

[0032] A method for preparing the cemented carbide with nearly spherical WC grains in the above embodiment includes the following steps:

[0033] (1) Mixing: Mix Co powder, TaC powder and WC powder, where the content of Co powder is 12.5wt%, the content of TaC powder is 2.45wt%, and the balance is WC powder; put the mixed powder on the drum Ball mill in a ball mill for 6 hours ...

Embodiment 2

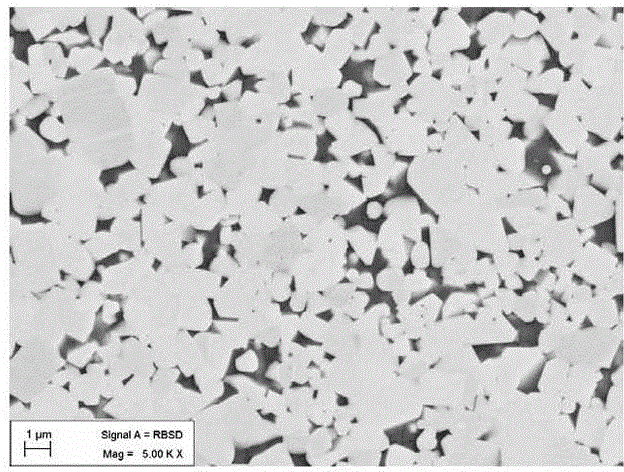

[0037] An example of the present invention figure 2 The cemented carbide with nearly spherical WC grains shown is composed of Co, cubic TaC and WC, wherein the content of Co is 8wt%, the content of cubic TaC is 1.85wt%, and the balance is WC, the C / W ratio of the cemented carbide is 0.813; the WC grains in the cemented carbide are nearly spherical, and the sphericity of the WC grains is 0.80.

[0038] In this embodiment, the FSSS grain size of the WC raw material is 2.56 μm, and the cemented carbide is a uniform cemented carbide.

[0039] A method for preparing the cemented carbide with nearly spherical WC grains in the above embodiment includes the following steps:

[0040] (1) Mixing: Mix Co powder, TaC powder and WC powder, where the content of Co powder is 8wt%, the content of TaC powder is 1.85wt%, the balance is WC powder; the mixed powder is placed in a roller ball mill Middle ball milling for 5 hours to obtain mixed slurry;

[0041] (2) Pressing: drying, granulating and pres...

Embodiment 3

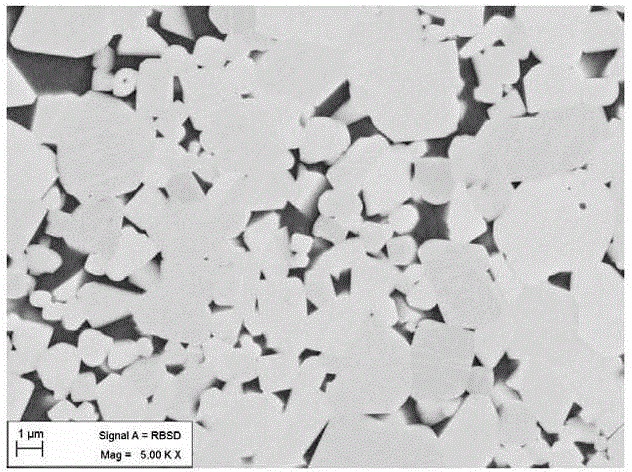

[0044] An example of the present invention image 3 The cemented carbide with nearly spherical WC grains shown is composed of Co, cubic TaC and WC, wherein the content of Co is 8wt%, the content of cubic TaC is 1.85wt%, and the balance is WC, the C / W ratio of the cemented carbide is 0.813; the WC grains in the cemented carbide are nearly spherical, and the sphericity of the WC grains is 0.87.

[0045] In this embodiment, the FSSS grain size of the WC raw material is 3.92 μm, and the cemented carbide is a uniform cemented carbide.

[0046] A method for preparing the cemented carbide with nearly spherical WC grains in the above embodiment includes the following steps:

[0047] (1) Mixing: Mix Co powder, TaC powder and WC powder, where the content of Co powder is 8wt%, the content of TaC powder is 1.85wt%, the balance is WC powder; the mixed powder is placed in a roller ball mill Middle ball milling for 4 hours to obtain mixed slurry;

[0048] (2) Pressing: drying, granulating and press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com