Low temperature wide-active temperature window SCR denitration catalyst and preparation method thereof

An active temperature window, denitration catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of high catalyst cost, increased denitration cost, catalyst deactivation and wear The problem is that the preparation method is simple and easy to operate, the resource utilization rate is improved, and the denitration activity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a method for preparing an SCR denitration catalyst with a low temperature and wide active temperature window. The preparation method includes the following steps:

[0028] (1) Add 20 g of purified attapulgite into 100 mL of distilled water, add 20 mL of manganese nitrate solution with a mass fraction of 50% and a certain amount of cerium nitrate hexahydrate and copper nitrate trihydrate in turn, and continue stirring for 1 h to obtain a catalyst suspension. liquid;

[0029] Attapulgite was purchased from Xuyi Meirui Attapulgite Processing Co., Ltd. (our products are refined through the processes of beneficiation, purification, drying, activation, grinding, etc.; brand: Meirui attapulgite Rongxi brand, item number: 00006, color classification: light grey);

[0030] (2) let the catalyst suspension stand for 4h;

[0031] (3) drying the obtained in step (2) at 80°C for 12h;

[0032] (4) The dried precipitate was placed in a muffle furnace,...

Embodiment 2

[0038] Add 20 g of purified attapulgite into 100 mL of distilled water, and then add 20 mL of manganese nitrate solution with a mass fraction of 50%, 2.15×10 -3 mol cerium nitrate hexahydrate, the molar ratio of cerium to copper between cerium nitrate hexahydrate and copper nitrate trihydrate is 1:40, keep stirring for 1h, then stand for 4h, dry at 80℃ for 12h, and then roast at 500℃ in air atmosphere 5h; finally grind and sieve, and take the part of 40-60 mesh as catalyst.

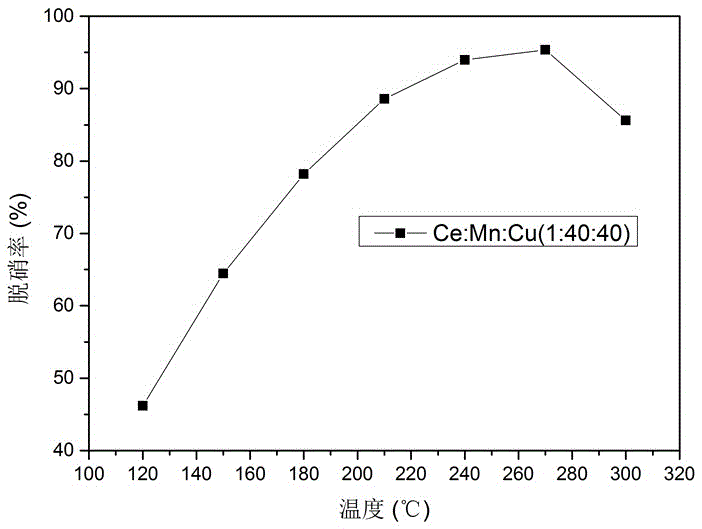

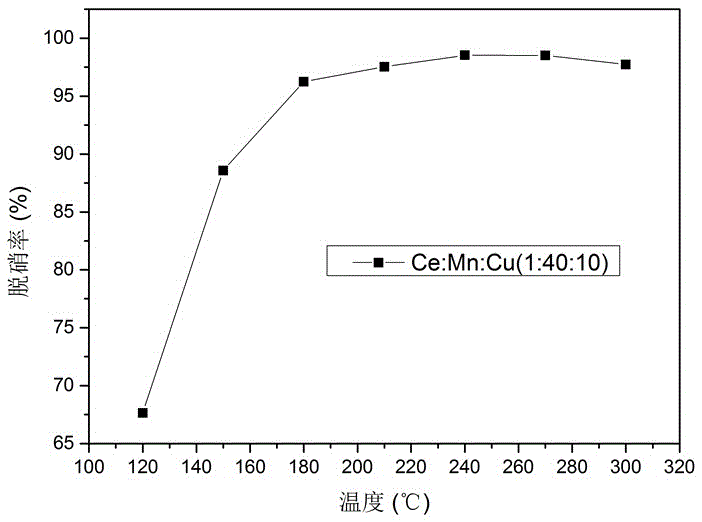

[0039] The catalyst was evaluated for SCR catalytic activity in a specified temperature window (120°C-300°C). The catalyst evaluation conditions are: the catalyst dosage is about 1.6g, the flue gas concentration is 500 ppm NO, 500 ppm NH 3 , 5% O 2 , N 2 It is an equilibrium gas, the total gas flow is 305 mL / min, and the reaction space velocity is 10000 h -1 . like figure 1 As shown, under the temperature conditions of 120 °C - 300 °C, the denitration rate of the catalyst can reach more than 88%. ...

Embodiment 3

[0041] Add 20 g of purified attapulgite into 100 mL of distilled water, and then add 20 mL of manganese nitrate solution with a mass fraction of 50%, 2.15×10 -3 mol cerium nitrate hexahydrate, the molar ratio of cerium and copper between cerium nitrate hexahydrate and copper nitrate trihydrate is 1:20, stirring continuously for 1h, then standing for 4h, drying at 80℃ for 12h, and then calcining at 500℃ in air atmosphere 5h; finally grind and sieve, and take the part of 40-60 mesh as catalyst.

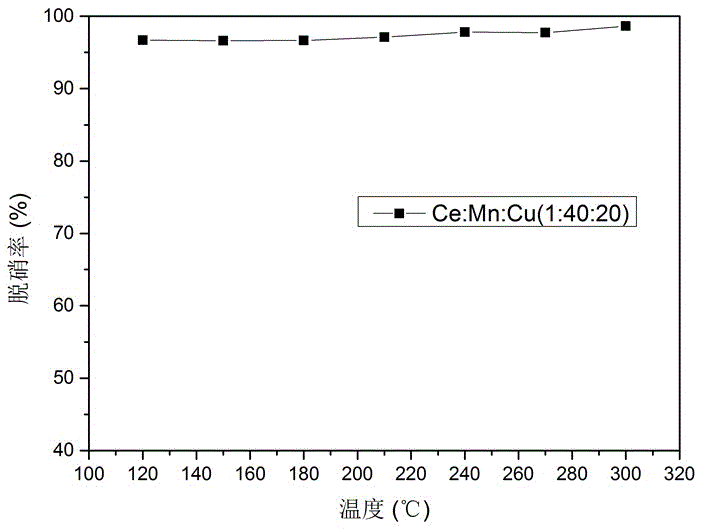

[0042] The catalyst was evaluated for SCR catalytic activity in a specified temperature window (120°C-300°C). The catalyst evaluation conditions are: catalyst dosage is 1.6g, flue gas concentration is 500 ppm NO, 500 ppm NH 3 , 5% O 2 , N 2 It is an equilibrium gas, the total gas flow is 305 mL / min, and the reaction space velocity is 10000 h -1 . like figure 2 As shown, at the reaction temperature of 120 °C, the denitration rate of the catalyst reached more than 92%, and at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com