Composite material for repairing bone defect

A composite material and bone defect technology, applied in medical science, prosthesis, etc., to achieve the effect of simple and feasible preparation process, good clinical application prospects, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Material preparation:

[0034] The preparation of nano-hydroxyapatite (nano HA powder) was prepared by conventional chemical precipitation; N, O-carboxymethyl chitosan was purchased from Qingdao Haihui Biological Engineering Co., Ltd., with a carboxymethyl substitution degree of 90.5%, The degree of deacetylation is 88.6%; p-dichlorobenzene, absolute ethanol, and citric acid are all analytically pure.

[0035] Preparation of composite material for repairing bone defect according to the present invention:

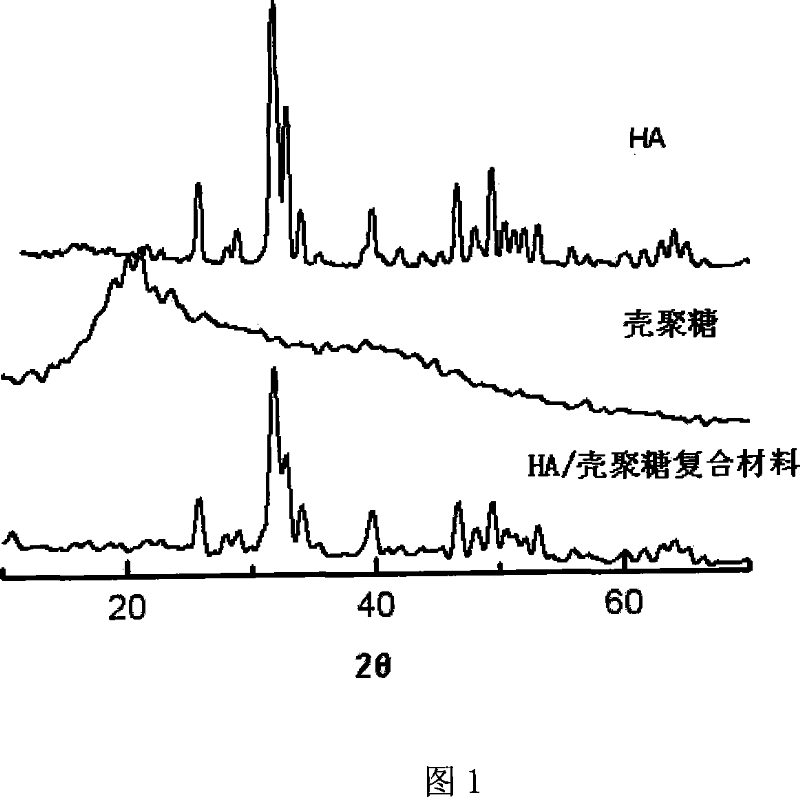

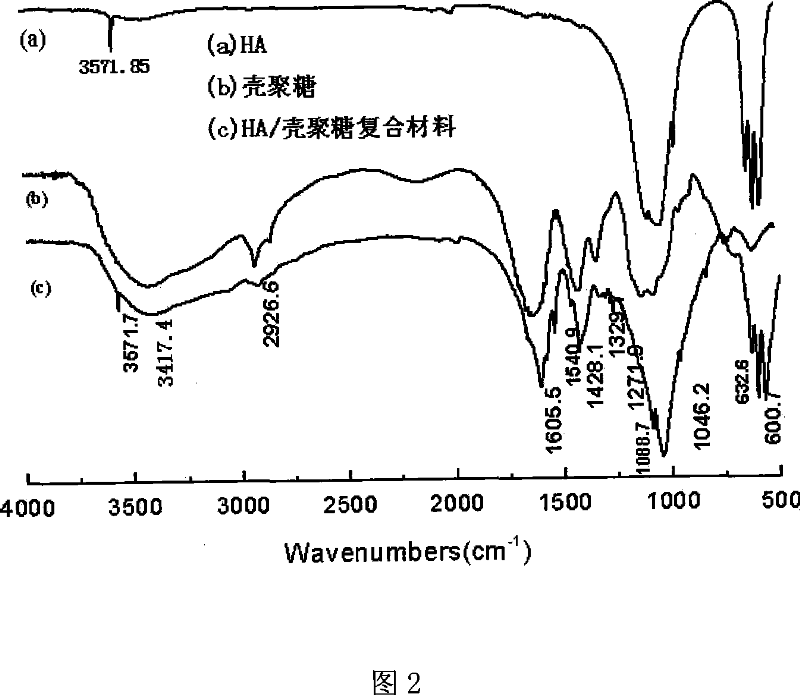

[0036](1) Nano-hydroxyapatite and carboxymethyl chitosan are proportioned respectively in the ratio of 6: 4 by mass ratio, and are fully mixed with mechanical ball milling;

[0037] (2) Then weigh the nano-hydroxyapatite / carboxymethyl chitosan composite powder and the pore-forming agent p-dichlorobenzene in a mass ratio of 1:1, grind and mix, and then ultrasonically vibrate for 2 hours to make it Mix well;

[0038] (3) adding mass percent in the mixture described i...

Embodiment 2

[0043] Preparation of nano-hydroxyapatite / carboxymethyl chitosan composite material for repairing bone defect according to the present invention:

[0044] (1) Nano-hydroxyapatite and carboxymethyl chitosan are proportioned respectively in a ratio of 7: 3 by mass ratio, and are fully mixed with mechanical ball milling;

[0045] (2) Then, the nano-hydroxyapatite / carboxymethyl chitosan composite powder and the pore-forming agent p-dichlorobenzene are weighed in a ratio of 1: 1.2 by mass, ground and mixed, and then ultrasonically oscillated for 2.5 hours to make It is thoroughly mixed;

[0046] (3) adding mass percent in the mixture described in step (2) is 16.7% citric acid solution and reconcile evenly, the citric acid solution consumption is as the criterion with the plasticity of mixture;

[0047] (4) Put the forming mixture into the artificial bone support standard mold, press forming, and keep the pressure for 80s;

[0048] (5) Demoulding, the formed composite material was...

Embodiment 3

[0051] Preparation of nano-hydroxyapatite / carboxymethyl chitosan composite material for repairing bone defect according to the present invention:

[0052] (1) Nano-hydroxyapatite and carboxymethyl chitosan are proportioned respectively in the ratio of 6.5: 3.5 by mass ratio, and are fully mixed with mechanical ball milling;

[0053] (2) Then weigh the nano-hydroxyapatite / carboxymethyl chitosan composite powder and the pore-forming agent p-dichlorobenzene in a mass ratio of 1:1.1, grind and mix, and then ultrasonically vibrate for 3 hours to make it Mix well;

[0054] (3) adding mass percent in the mixture described in step (2) is 16.7% citric acid solution and reconcile evenly, the citric acid solution consumption is as the criterion with the plasticity of mixture;

[0055] (4) Put the forming mixture into the artificial bone support standard mold, press forming, and hold the pressure for 100s;

[0056] (5) Demoulding, the formed composite material was placed in air for 5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com