Preparation method of chromium-silicon alloy sputtering target material

A chromium-silicon alloy and sputtering target technology, which is applied in the field of preparation of chromium-silicon alloy sputtering targets, and achieves the effects of meeting the requirements of purity and density and having a simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

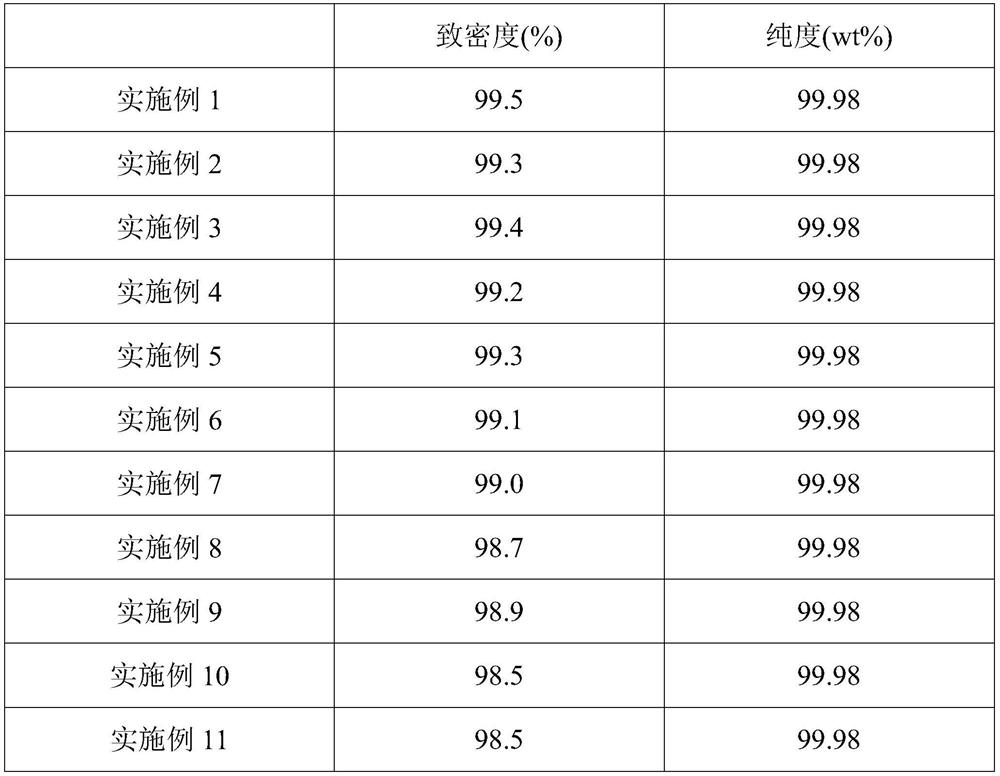

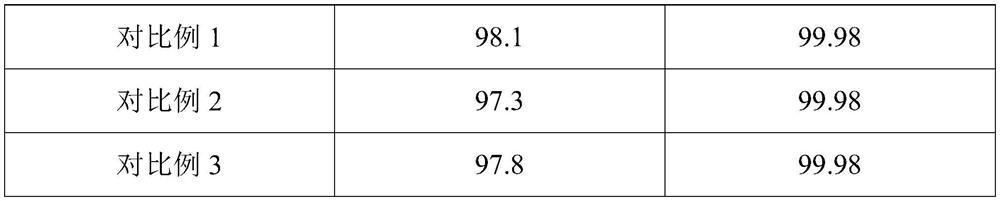

Examples

Embodiment 1

[0063] 本实施例提供了一种铬硅合金溅射靶材的制备方法,所述制备方法包括如下步骤:

[0064] (1)V型混粉机中,氮气气氛下球磨混合铬粉与硅粉,得到混合料,混合料中硅粉的质量分数为15wt%;所述铬粉的粒径范围为30-60μm,铬粉的纯度为5N,所述硅粉的粒径<2μm,硅粉的纯度为5N;所述球磨混合所用研磨球为硅球,料球比为10:1,球磨混合的时间为40h;

[0065] (2)步骤(1)所得混合料装入石墨模具,压实使平面度≤0.3mm,然后抽真空至真空度降至70Pa;

[0066] (3)完成步骤(2)所述抽真空处理后,进行第一热处理,第一热处理过程中压力不超过6MPa;所述第一热处理的温度为1150℃;第一热处理的升温速率为8℃ / min;第一热处理的保温时间为90min;

[0067] (4)依次进行第二热处理、第一加压、第二加压与保温保压;所述第二热处理的温度为1320℃,升温速率为5℃ / min,保温时间80min;所述第一加压为45min均匀加压至20MPa;所述第二加压为45min均匀加压至30MPa;所述保温保压的时间为120min;

[0068] (5)保温保压结束后进行氮气置换,至压力为-0.07MPag,然后随炉冷却至150℃;

[0069] (6)机加工至所需尺寸,完成铬硅合金溅射靶材的制备。

Embodiment 2

[0071] 本实施例提供了一种铬硅合金溅射靶材的制备方法,所述制备方法包括如下步骤:

[0072] (1)V型混粉机中,氩气气氛下球磨混合铬粉与硅粉,得到混合料,混合料中硅粉的质量分数为15wt%;所述铬粉的粒径范围为30-60μm,铬粉的纯度为5N,所述硅粉的粒径<3μm,硅粉的纯度为5N;所述球磨混合所用研磨球为铬球,料球比为9:1,球磨混合的时间为38h;

[0073] (2)步骤(1)所得混合料装入石墨模具,压实使平面度≤0.2mm,然后抽真空至真空度降至80Pa;

[0074] (3)完成步骤(2)所述抽真空处理后,进行第一热处理,第一热处理过程中压力不超过6MPa;所述第一热处理的温度为1120℃;第一热处理的升温速率为6℃ / min;第一热处理的保温时间为95min;

[0075] (4)依次进行第二热处理、第一加压、第二加压与保温保压;所述第二热处理的温度为1300℃,升温速率为4.5℃ / min,保温时间90min;所述第一加压为40min均匀加压至20MPa;所述第二加压为40min均匀加压至30MPa;所述保温保压的时间为110min;

[0076] (5)保温保压结束后进行氩气置换,至压力为-0.07MPag,然后随炉冷却至180℃;

[0077] (6)机加工至所需尺寸,完成铬硅合金溅射靶材的制备。

Embodiment 3

[0079] 本实施例提供了一种铬硅合金溅射靶材的制备方法,所述制备方法包括如下步骤:

[0080] (1)V型混粉机中,氦气气氛下球磨混合铬粉与硅粉,得到混合料,混合料中硅粉的质量分数为15wt%;所述铬粉的粒径范围为30-60μm,铬粉的纯度为5N,所述硅粉的粒径<3μm,硅粉的纯度为5N;所述球磨混合所用研磨球为铬球,料球比为11:1,球磨混合的时间为42h;

[0081] (2)步骤(1)所得混合料装入石墨模具,压实使平面度≤0.4mm,然后抽真空至真空度降至60Pa;

[0082] (3)完成步骤(2)所述抽真空处理后,进行第一热处理,第一热处理过程中压力不超过6MPa;所述第一热处理的温度为1180℃;第一热处理的升温速率为9℃ / min;第一热处理的保温时间为85min;

[0083](4) Carry out the second heat treatment, the first pressurization, the second pressurization and heat preservation and pressure keeping in sequence; the temperature of the second heat treatment is 1330°C, the heating rate is 5.5°C / min, and the holding time is 70min; the first The pressurization is uniformly pressurized to 20MPa for 50min; the second pressurization is uniformly pressurized to 30MPa for 50min; the time for the heat preservation and pressure holding is 140min;

[0084] (5) After heat preservation and pressure holding, helium replacement is carried out until the pressure is -0.07MPag, and then cooled to 180°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com