Method for enabling waste active carbon powder to be used for sintering, sintering mixture and sinter

A technology for sintering mixed materials and waste activated carbon, which is applied in the field of sintering and can solve problems such as affecting the output of sintered ore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

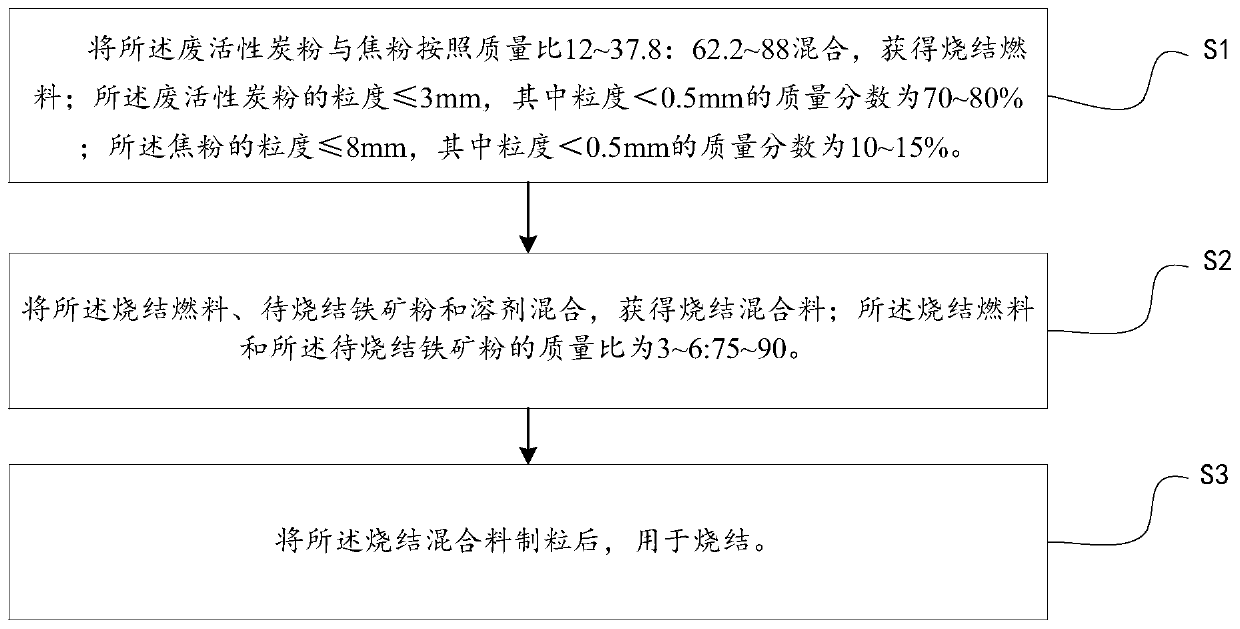

Method used

Image

Examples

Embodiment 1 to Embodiment 5

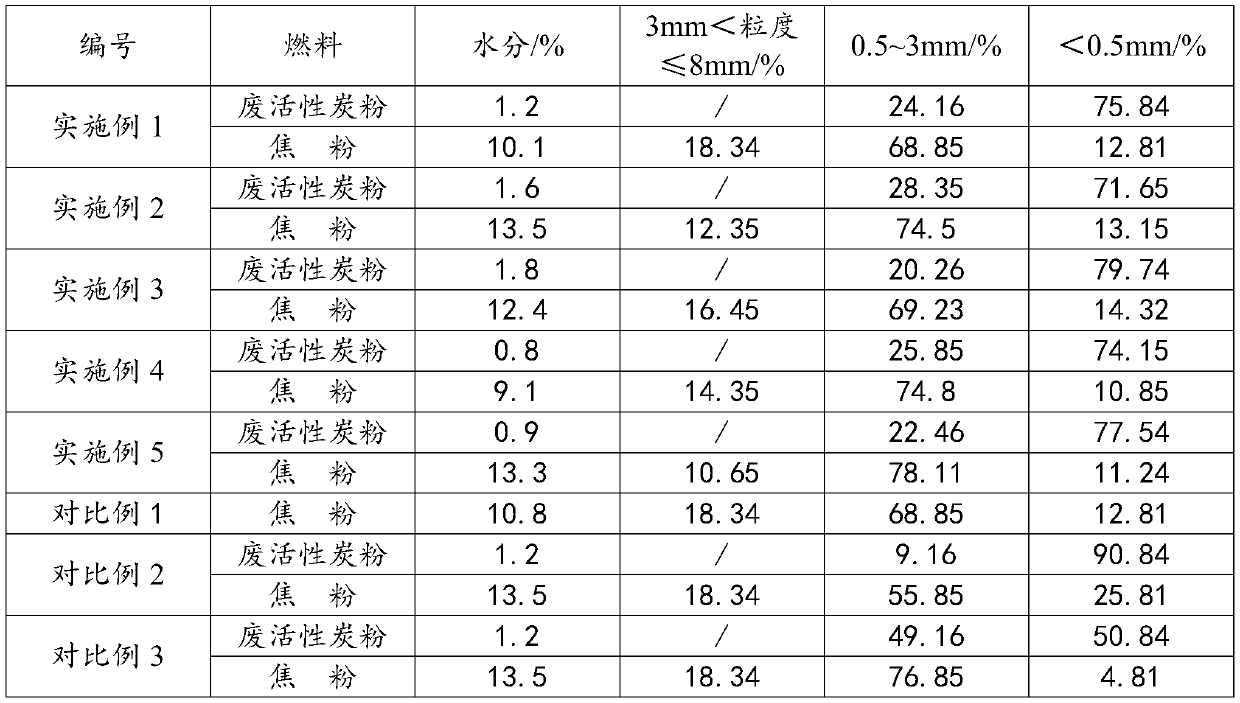

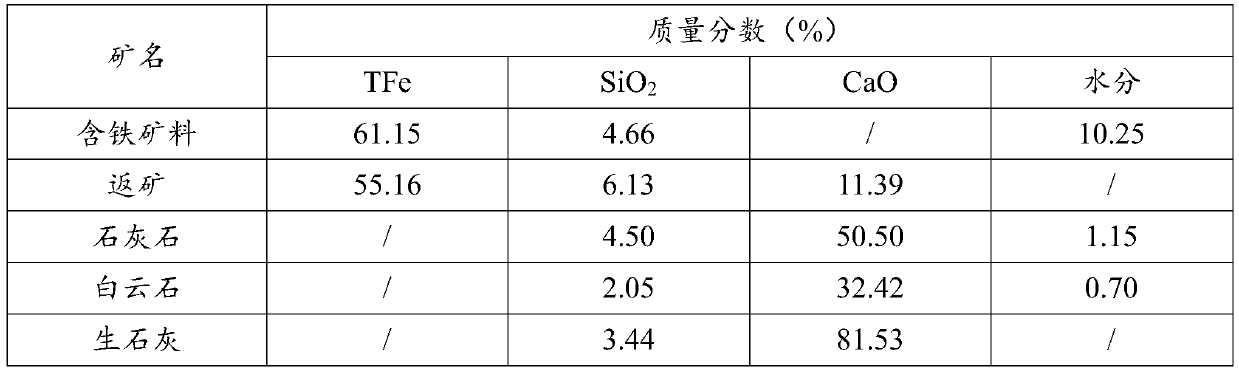

[0052] Embodiment 1 to embodiment 5 provide a kind of method that waste activated carbon powder is used for sintering, sintering mixture and sintered ore, and sintering mixture comprises activated carbon, coke powder, iron ore material and solvent, and the proportioning of waste activated carbon powder is 0.6-1.4%, its moisture content and particle size composition are shown in Table 1; the proportion of coke powder is 3.1-3.7%, its moisture content and particle size composition are shown in Table 1, and the alkalinity of sintered ore is 1.9-2.0. The iron ore material is selected from the returned ore and the mixed ore. The mixed ore is the ore after mixing various iron ore materials. The solvents include limestone, dolomite and quicklime, the compositions of which are shown in Table 2. The specific ratio of each raw material is shown in Table 3.

[0053] The sintering mixture is mixed with water, granulated, distributed, ignited and sintered to obtain sintered ore. Wherein,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com