Low temperature resisting cast steel material and thermal treatment process of casting made from low temperature resisting cast steel material

A technology of low temperature resistance and steel casting, applied in the field of steel casting, to achieve the effect of superior comprehensive mechanical properties, excellent welding performance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

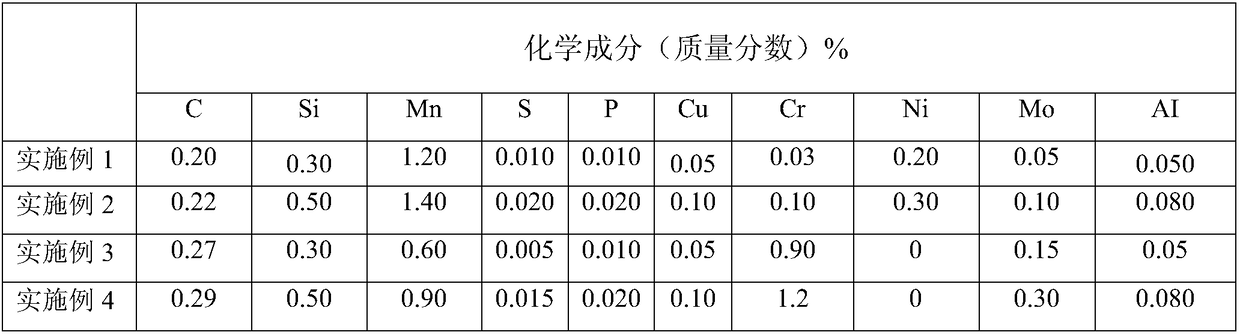

[0032] The chemical composition of table 1 embodiment 1-4 cast steel material

[0033]

[0034] After the casting is poured, it is cooled to below 540°C at a speed that does not damage its quality. Before heat treatment, the castings are fully cleaned, no molding material is attached to the surface, and the sand core in the inner cavity is cleaned.

[0035] The heat treatment furnace temperature is measured and controlled by thermocouples and devices with automatic control functions, and can automatically record time-temperature curves. Each curve should record the date and furnace number for identification.

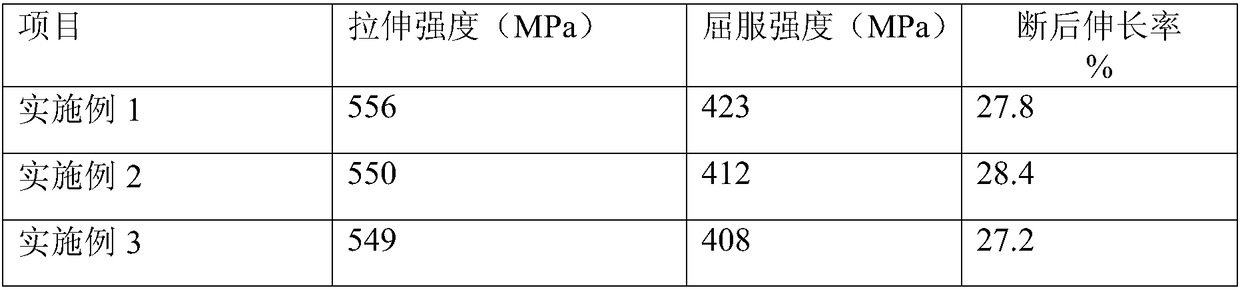

[0036] The specific heat treatment steps are: put the casting in a normalizing furnace, raise the temperature to 910°C±10°C, keep it warm for 3.5-4.5h, take the casting out of the furnace, and cool it in air until the temperature is lower than 370°C. Put the casting in the quenching furnace, raise the temperature to 910°C±10°C, keep the temperature according to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com