High-hardness isostatic graphite and preparation method thereof

A technology of isostatic pressing and isostatic pressing, which is applied in the field of static-pressed graphite and its preparation, can solve the problems of insignificant improvement of the electrochemical properties of graphite materials and complicated operation, and achieve improved bulk density and flexural strength, uniform Good performance, improving fluidity and compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

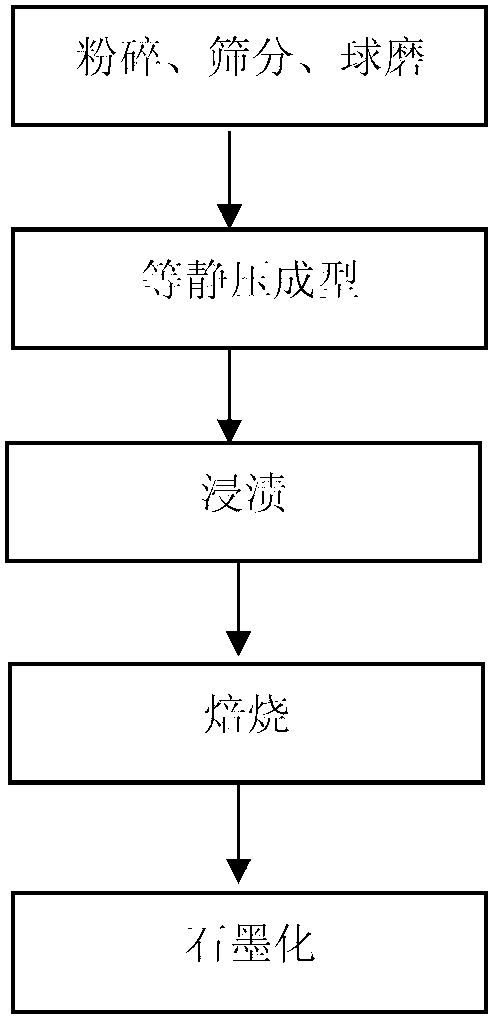

Method used

Image

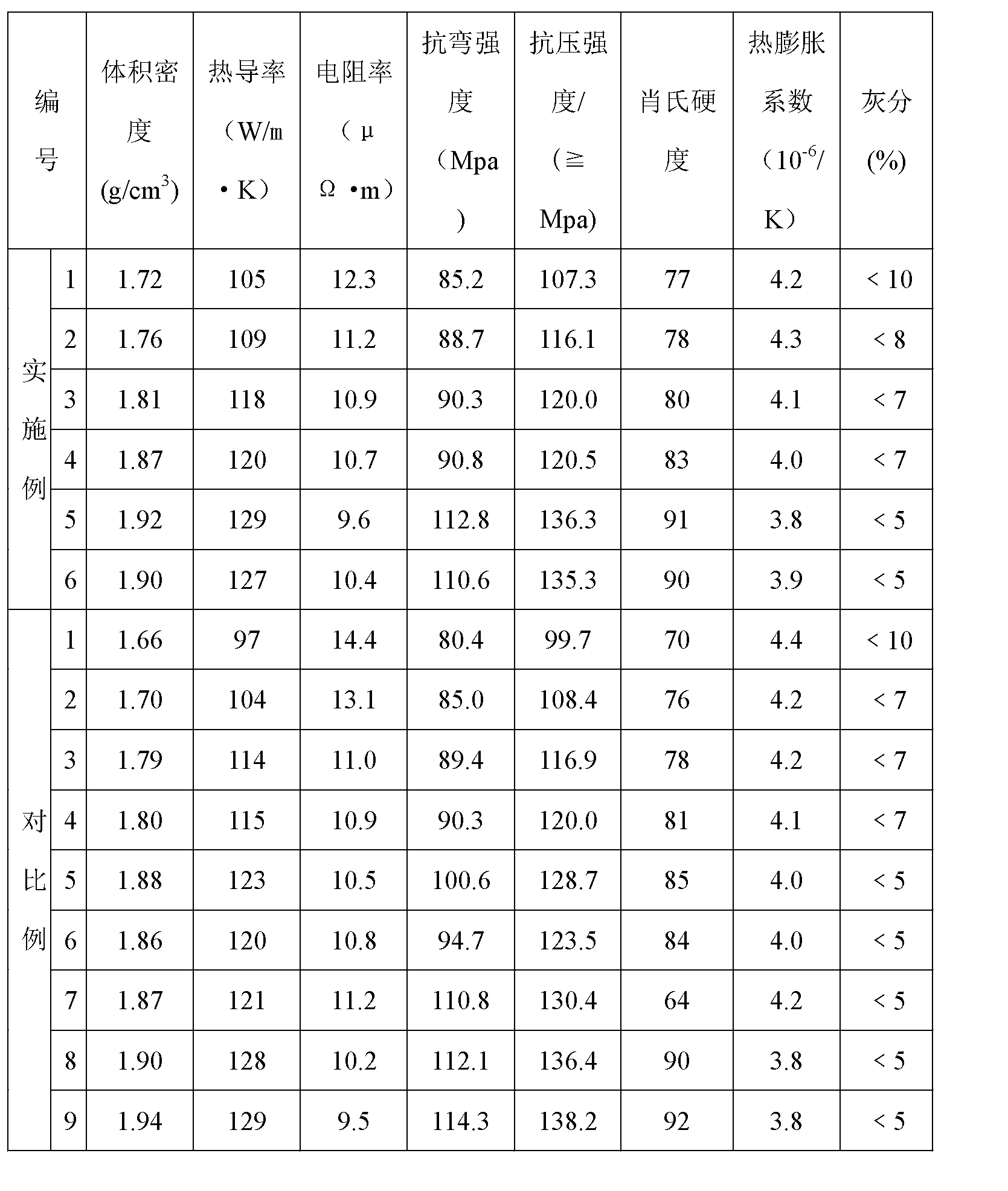

Examples

Embodiment 1

[0075] Example 1 Preparation of isostatic graphite of the present invention

[0076] (1) Crushing and screening

[0077] Weigh petroleum coke and mesophase carbon microspheres, control their mass ratio to 5:5, place them in an airflow mill, and grind them through airflow to obtain a mixed powder with an average particle size of 3 μm. The mixed powder of the mixed powder is passed through a 1000 mesh sieve to obtain a fine raw material powder; after adding carbon black with a mass fraction of 4% in the fine raw material powder, it is put into a ball mill jar, and ball milled at a speed of 260r / min on a planetary ball mill 2h, make raw material mixture;

[0078] (2) Isostatic pressing

[0079] Preheat the raw material mixture obtained in step (1) to 80°C, put it into a rubber mold, and cold-press it under a pressure of 200Mpa for isostatic pressing. After holding the pressure for 18 minutes, it is demoulded to obtain isostatic pressing Formed body;

[0080] (3...

Embodiment 2

[0087] Example 2 Preparation of isostatic graphite of the present invention

[0088] (1) Crushing and screening

[0089] Weigh pitch coke and mesophase carbon microspheres, control the mass ratio of pitch coke:mesophase carbon microspheres to 4:6, place them in an airflow mill, and grind them through airflow to obtain an average particle size of 5 μm The mixed powder is passed through an 800-mesh sieve to obtain a raw material fine powder; after adding carbon black with a mass fraction of 6% in the raw material fine powder, it is put into a ball mill jar, and the planetary ball mill Ball milling at a speed of 260r / min for 2h to obtain a raw material mixture;

[0090] (2) Isostatic pressing

[0091] Preheat the raw material mixture prepared in step (1) to 80°C, put it into a rubber mold, and cold-press it under a pressure of 200Mpa for isostatic pressing, and release the mold after holding the pressure for 20 minutes to obtain an isostatic Pressed body;

[009...

Embodiment 3

[0099] Example 3 Preparation of isostatic graphite of the present invention

[0100] (1) Crushing and screening

[0101] Weigh pitch coke and mesophase carbon microspheres, control the mass ratio of pitch coke:mesophase carbon microspheres to 3:7, place them in an airflow mill, and grind them through airflow to obtain an average particle size of 6 μm The mixed powder is passed through an 800-mesh sieve to obtain a raw material fine powder; after adding carbon black with a mass fraction of 8% in the raw material fine powder, it is put into a ball mill jar, and the planetary ball mill Ball milling at a speed of 260r / min for 2h to obtain a raw material mixture;

[0102] (2) Isostatic pressing

[0103] Preheat the raw material mixture obtained in step (1) to 80°C, put it into a rubber mold, and cold press it under a pressure of 240Mpa for isostatic pressing. After holding the pressure for 18 minutes, the mold is released to obtain an isostatic pressing Formed body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com