SnSe/rGO thermoelectric composite material and preparation method thereof

A composite material and thermoelectric technology, applied in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, nanotechnology for materials and surface science, etc., can solve the problem of reducing economy, nanoscale morphology and size Difficult to control, time-consuming and other problems, to achieve the effect of simple preparation device, improved thermoelectric figure of merit, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

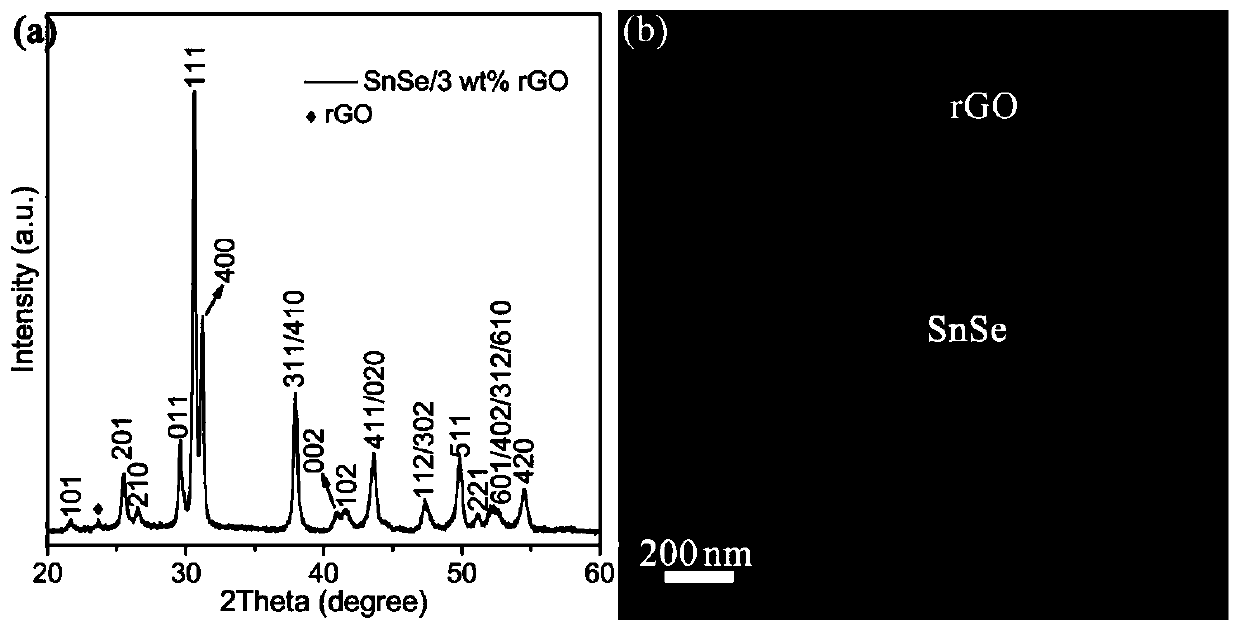

[0034] Embodiment 1: see figure 1 , a kind of preparation method of SnSe / rGO thermoelectric composite material, prepare SnSe / rGO (mass fraction x=3wt% of rGO) composite material, concrete steps comprise:

[0035] S1: Weigh 62.3mg of graphene oxide and add it into a flask filled with 10ml of deionized water, and sonicate for 2 hours at 100W power;

[0036] S2: take 10mmol SnCl 2 2H 2 O is fully reacted with 100mmol NaOH in 40ml deionized water to obtain Na 2 SnO 2 aqueous solution, and stirred under argon atmosphere, to obtain Na 2 SnO 2 aqueous solution;

[0037] SnCl 2 2H 2 The reaction formula of O and NaOH is SnCl 2 +4NaOH→Na 2 SnO 2 +2NaCl+2H 2 O;

[0038] S3: Weigh 0.625g of NaBH 4 , adding Na in S2 2 SnO 2 solution, mix well.

[0039] S4: Add the graphene oxide dispersion obtained in S1 to the Na obtained in S3 2 SnO 2 In the aqueous solution, under an argon atmosphere, stir with a magnetic stirrer at a rate of 800r / min for 1h, and then heat the soluti...

Embodiment 2

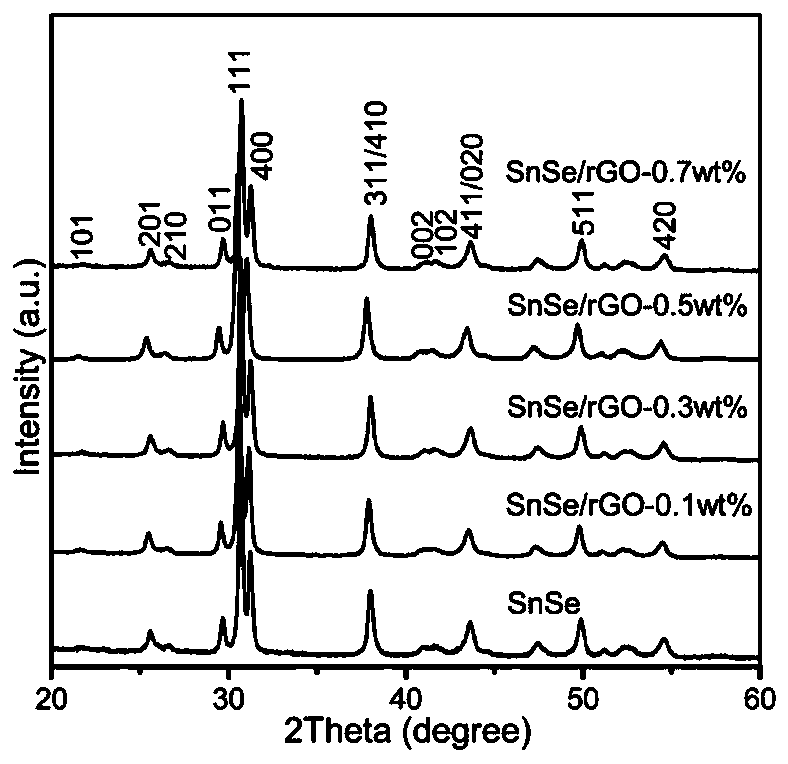

[0045] Example 2: see Figure 2-Figure 6 , a preparation method of SnSe / rGO thermoelectric composite material, preparation of SnSe / rGO (mass fraction x=0.7wt% of rGO) composite material preparation, concrete steps include:

[0046] S1: Weigh 14.1mg of graphene oxide and add it into a flask filled with 10ml of deionized water, and ultrasonicate for 2h at 100W power;

[0047] S2: take 10mmol SnCl 2 2H 2 O is fully reacted with 100mmol NaOH in 40ml deionized water to obtain Na 2 SnO 2 aqueous solution, and stirred under argon atmosphere, to obtain Na 2 SnO 2 aqueous solution;

[0048] SnCl 2 2H 2 The reaction formula of O and NaOH is SnCl 2 +4NaOH→Na 2 SnO 2 +2NaCl+2H 2 O;

[0049] S3: Weigh 0.1416g of NaBH 4 , adding Na in S2 2 SnO 2 solution, mix well.

[0050] S4: Add the graphene oxide dispersion obtained in S1 to the Na obtained in S3 2 SnO 2 In the aqueous solution, under an argon atmosphere, stir with a magnetic stirrer at a rate of 800r / min for 1h, and ...

Embodiment 3

[0056] Embodiment 3: see Figure 2-Figure 6 , a kind of preparation method of SnSe / rGO thermoelectric composite material, preparation SnSe / rGO (mass fraction x=0.5wt% of rGO) composite material preparation, concrete steps comprise:

[0057] S1: Weigh 10.5 mg of graphene oxide and add it to a flask filled with 10 ml of deionized water, and ultrasonicate for 2 hours at a power of 100 W;

[0058] S2: take 10mmol SnCl 2 2H 2 O is fully reacted with 100mmol NaOH in 40ml deionized water to obtain Na 2 SnO 2 aqueous solution, and stirred under argon atmosphere, to obtain Na 2 SnO 2 aqueous solution;

[0059] SnCl 2 2H 2 The reaction formula of O and NaOH is SnCl 2 +4NaOH→Na 2 SnO 2 +2NaCl+2H 2 O;

[0060] S3: Weigh 0.1055g of NaBH 4 , adding Na in S2 2 SnO 2 solution, mix well.

[0061] S4: Add the graphene oxide dispersion obtained in S1 to the Na obtained in S3 2 SnO 2 In the aqueous solution, under an argon atmosphere, stir with a magnetic stirrer at a rate of 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com