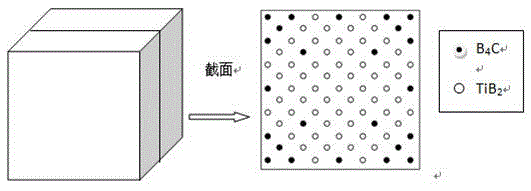

Preparation method of TiB2 (titanium diboride) gradient ceramic with hard surface and tough core

A ceramic and surface-hard technology, applied in the field of non-oxide-based ceramic materials, can solve the problems of difficult bonding and easy falling off, and achieve the effect of continuous hardness change, good overall toughness and high fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

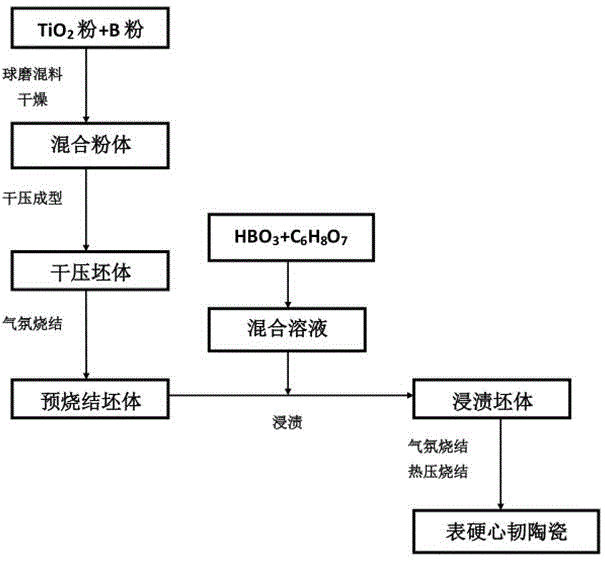

[0032] Preparation of Table Hard-core Tough TiB 2 The specific method of gradient ceramics is as follows:

[0033] (1) 99% TiO with a purity of 2 Powder, B powder with a purity of 98% as raw material, according to TiO 2 The mass fraction ratio of powder and B powder is 69%: 31% is mixed with acetone as a solvent, and Si 3 N 4 The ball is a ball milling medium, mixed on a roller ball mill for 12 hours, and dried to obtain TiO 2 -B mixed powder;

[0034] (2) TiO 2 -B The mixed powder was put into a mold, and tableted on a dry press with a molding pressure of 30 MPa and a holding time of 2 minutes.

[0035] (3) TiO 2 -B The green body is put into a boron nitride crucible for pre-sintering, and the temperature is raised to 900°C at a heating rate of 10°C / min and kept for 2 hours. The sintering atmosphere during the whole process is 1 atm of argon.

[0036] (4) Configure HBO 3 with C 6 h8 o 7 The mass ratio is 32%: 68% saturated mixed solution, the solution temperature i...

Embodiment 2

[0040] Prepare TiB according to embodiment 1 method 2 Gradient ceramics, wherein step (4) is repeated for 2 times of impregnation. The prepared ceramic material has a hardness of 25GPa and a fracture toughness of 5.5MPa m on the surface of the ceramic 1 / 2 ; In the central part of the ceramic, the hardness is 20.5GPa, and the fracture toughness is 7.5MPa m 1 / 2 .

Embodiment 3

[0042] Prepare TiB according to embodiment 1 method 2 Gradient ceramics, wherein step (4) is repeated for 7 times of impregnation. The prepared ceramic material has a hardness of 29GPa and a fracture toughness of 4MPa·m in the ceramic surface layer 1 / 2 ;In the central part of the ceramic, the hardness is 22GPa, and the fracture toughness is 7.5MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com