Preparation and application of lithium polymethylallyl sulfonate for lithium battery negative electrode protection

A technology of lithium polymethacrylate sulfonate and lithium methacrylate sulfonate, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as shortage, reduce the loss of active substances, improve cycle performance, prevent effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation process of described solid catalyst is:

[0047] a. Under the protection of argon, add anhydrous magnesium chloride, n-heptane and n-butanol to the container, raise the temperature to 85-90°C, stir for 3-3.2h, then cool down to 58-60°C and then add carbon dioxide Silicon, continue to stir and react for 2.8-3.2h. After the reaction is completed, the solid is collected by suction filtration to obtain MgCl 2 / SiO 2 Composite carrier; the addition ratio between anhydrous magnesium chloride, n-heptane, n-butanol and silicon dioxide is 1-1.2mol: 4.5-5.5mL: 3.8-4mol: 0.78-0.82mol;

[0048] b. Under argon protection, add MgCl to the container 2 / SiO 2 Composite carrier, titanium tetrachloride and n-heptane, react at 86-90°C for 1.8-2h, after the reaction is completed, filter while hot, wash with n-hexane, and dry to obtain a solid catalyst; MgCl 2 / SiO 2 Composite carrier, titanium tetrachloride and n-heptane 4.8-5mol: 4.6-5.2mol: 48-50mL.

[0049] The app...

Embodiment 1

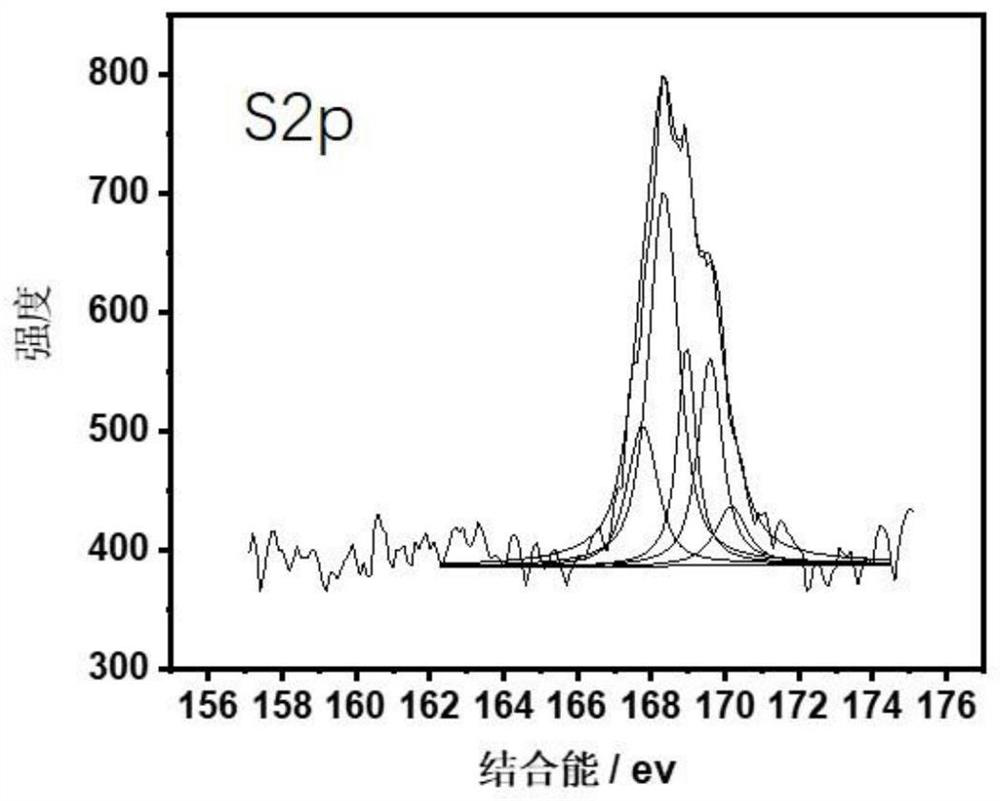

[0052] A kind of preparation of lithium battery negative electrode protection polymethyl propylene sulfonate lithium, comprises following preparation steps:

[0053] (1) Dissolve methylpropenesulfonic acid in water, add 2.2M lithium hydroxide aqueous solution under ice bath and nitrogen conditions, the molar weight of lithium hydroxide is 2.5 times of methylpropenesulfonic acid molar weight, and react under normal temperature After 23 hours, after the reaction was completed, 1.1M dilute hydrochloric acid was added to the reaction liquid until solids were precipitated, and after being fully stirred, filtered, and the solids were collected to obtain lithium methacrylate;

[0054] (2) Heat lithium methacrylate, triethylaluminum and solid catalyst synthesized in step (1) to 60°C for 23.8 hours, add acidified ethanol to terminate the reaction, filter, and dry to obtain lithium polymethacrylate sulfonate ; The molar ratio of triethylaluminum to the solid catalyst is 240:1.1, the mol...

Embodiment 2

[0064] A kind of preparation of lithium battery negative electrode protection polymethyl propylene sulfonate lithium, comprises following preparation steps:

[0065] (1) Dissolve methylpropenesulfonic acid in water, under ice bath and nitrogen conditions, add 2M lithium hydroxide aqueous solution, the molar weight of lithium hydroxide is 1.2 times of methylpropenesulfonic acid molar weight, react at room temperature for 22h , after the reaction is completed, add 1M dilute hydrochloric acid to the reaction solution until solids are precipitated, after fully stirring, filter, collect the solids to obtain lithium methene sulfonate;

[0066] (2) Heat lithium methacrylate, triethylaluminum and solid catalyst synthesized in step (1) to 58°C for 23.5 hours, add acidified ethanol to terminate the reaction, filter, and dry to obtain lithium polymethacrylate sulfonate ; The molar ratio of triethylaluminum to the solid catalyst is 240:1, the molar weight of the solid catalyst is 5% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com