Diluent for high temperature resistant salt-tolerant drilling fluid and preparation method of diluent

A technology of diluent and drilling fluid, which is applied in the field of diluent for high temperature and salt resistance drilling fluid and its preparation, can solve the problems of large livestock and environmental pollution, poor anti-pollution ability, and heavy human and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

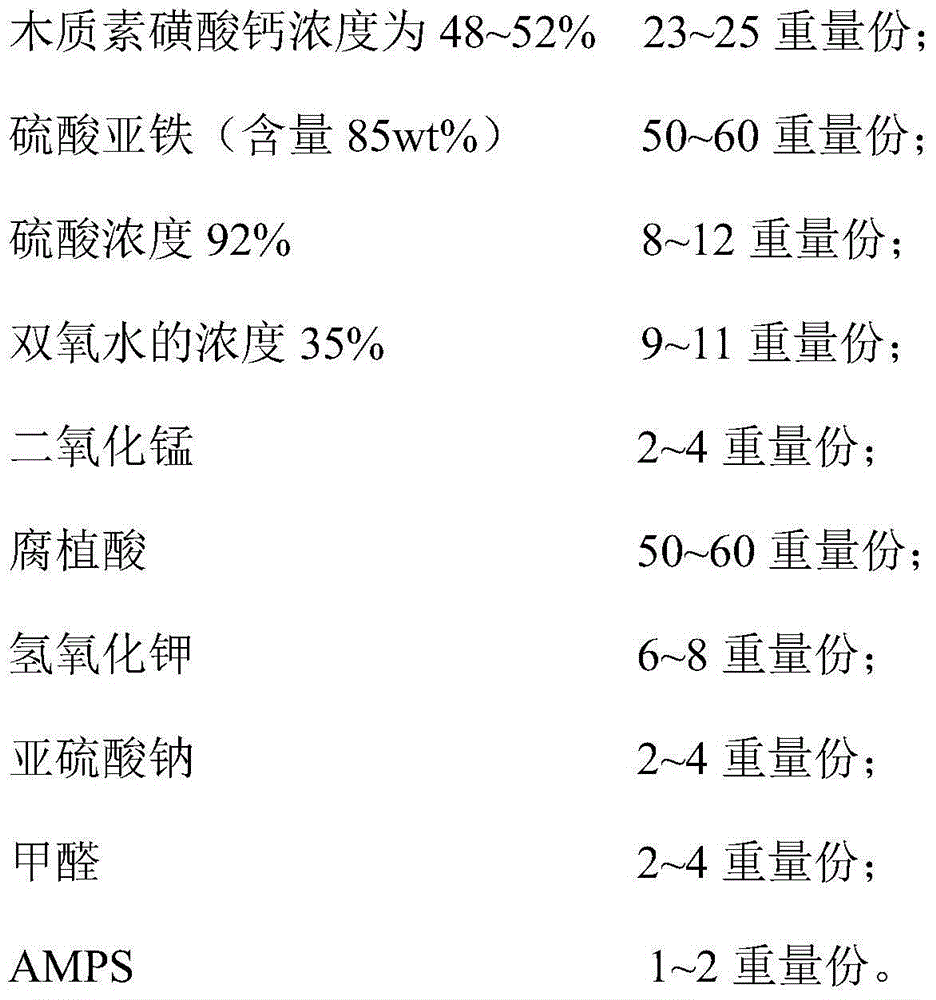

[0058] The specific steps of the preparation method of the high temperature and salt resistant drilling fluid diluent of the present invention are as follows:

[0059] (1) Add 8 parts by weight of water in the batching container, 12 parts by weight of sulfuric acid with a concentration of 92%, 50 parts by weight of ferrous sulfate with a content of 85wt%, after stirring evenly, add 11 parts by weight of a concentration of 35% Hydrogen peroxide, add hydrogen peroxide slowly, keep the temperature below 78°C, and the equivalent concentration of ferric sulfate is 8.0-10.0N;

[0060] (2) adding the concentration of 200 parts by weight to the reaction vessel successively under normal temperature and pressure is the calcium lignosulfonate of 48~50% and the ferric sulfate displacing agent prepared in the step (1), the temperature in the reaction vessel is reduced after feeding Rise to 85°C, keep warm for 30 minutes, filter the replaced liquid material, and remove the precipitated calc...

Embodiment 2

[0065] The specific steps of the preparation method of the high temperature and salt resistant drilling fluid diluent of the present invention are as follows:

[0066] (1) Add 10 parts by weight of water in the batching container, 8 parts by weight of sulfuric acid with a concentration of 92%, 60 parts by weight of ferrous sulfate with a content of 85wt%, after stirring evenly, add 9 parts by weight of a concentration of 35% sulfuric acid Hydrogen peroxide, add hydrogen peroxide slowly, keep the temperature below 78°C, and the equivalent concentration of ferric sulfate is 8.0-10.0N;

[0067] (2) adding the concentration of 220 parts by weight to the reaction vessel successively under normal temperature and pressure is the calcium lignosulfonate of 48~50% and the ferric sulfate displacing agent prepared in the step (1), the temperature in the reaction vessel is reduced after feeding Rise to 85°C, keep warm for 30 minutes, filter the replaced liquid material, and remove the prec...

Embodiment 3

[0072] The specific steps of the preparation method of the high temperature and salt resistant drilling fluid diluent of the present invention are as follows:

[0073] (1) Add 9 parts by weight of water in the batching container, 10 parts by weight of sulfuric acid with a concentration of 92%, 55 parts by weight of ferrous sulfate with a content of 85wt%, after stirring evenly, add 10 parts by weight of a concentration of 35% Hydrogen peroxide, add hydrogen peroxide slowly, keep the temperature below 78°C, and the equivalent concentration of ferric sulfate is 8.0-10.0N;

[0074] (2) add the concentration of 210 weight parts successively to the reaction vessel under normal temperature and pressure and be the calcium lignosulfonate of 48~50% and the ferric sulfate displacing agent prepared in the step (1), the temperature in the reaction vessel will be reduced after feeding Rise to 83°C, keep warm for 35 minutes, filter the replaced liquid material, and remove the precipitated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com