High-workability polycarboxylic water reducer and preparation method and use method thereof

A polycarboxylic acid-based, water-reducing agent technology, applied in the field of building materials, can solve problems such as unsatisfactory workability, and achieve the effects of being conducive to large-scale industrial production, convenient operation, and high workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

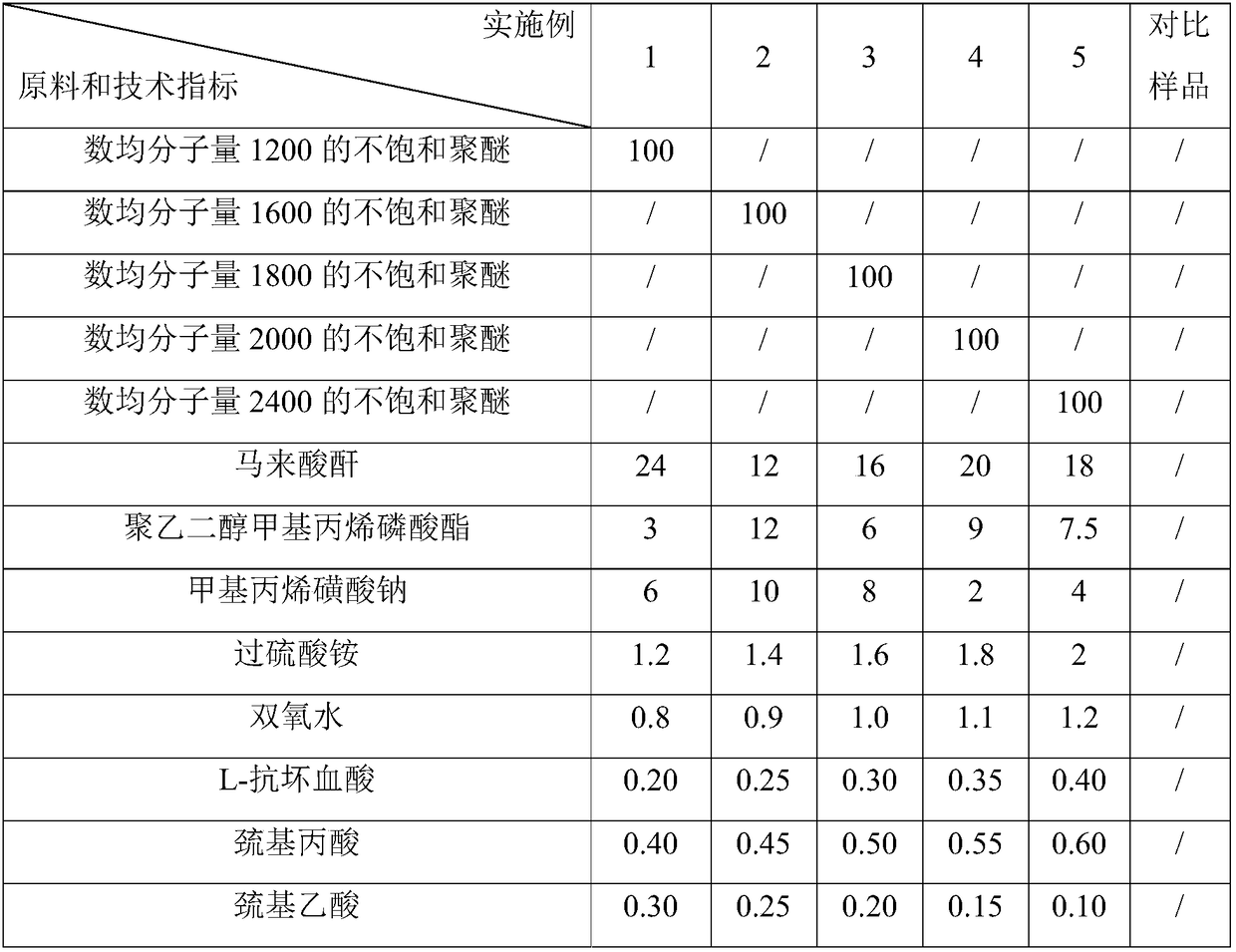

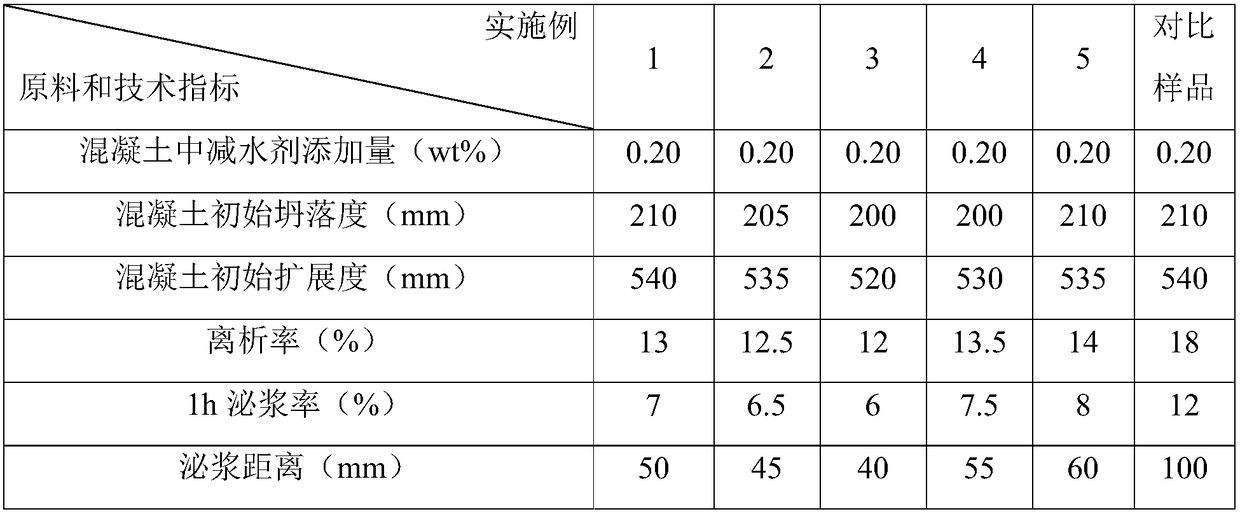

Examples

Embodiment 1

[0039] (1) Preparation before polymerization:

[0040] Preparation of mixture A: Weigh 100 parts by weight of unsaturated polyether with a number average molecular weight of 1200 and 20 parts by weight of water, put them into a polymerization reactor, stir evenly, heat up to 60°C, and set aside;

[0041] Preparation of solution B: Weigh 24 parts by weight of maleic anhydride, 3 parts by weight of polyethylene glycol methacrylate phosphate, 6 parts by weight of sodium methacrylate and 30 parts by weight of water, stir evenly, and prepare for dropwise addition;

[0042]Preparation of solution C: Weigh 0.20 parts by weight of L-ascorbic acid, 0.40 parts by weight of mercaptopropionic acid, 0.30 parts by weight of thioglycolic acid and 40 parts by weight of water, stir evenly, and prepare dropwise;

[0043] Preparation of solution D: weigh 0.8 parts by weight of hydrogen peroxide and 40 parts by weight of water, stir evenly, and prepare to add dropwise;

[0044] (2) Polymerizatio...

Embodiment 2~5

[0048] The preparation methods of Examples 2-5 are the same as those of Example 1, and the differences are specifically marked in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com