Method for volume acid-fracturing reformation of seam net of carbonate reservoir

A carbonate reservoir and fracture network technology, applied in chemical instruments and methods, mining fluids, earthwork drilling and production, etc., can solve problems such as heavy workload and coordination difficulty on site, collapse of overlying strata structure, short circuit of fracture channels, etc. , to achieve the effect of retarding the acid rock reaction, developing the fracture system, and reducing the wellhead pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The low-viscosity drop-resistance slick water acid liquid is configured, and the configuration method is as follows: weigh each raw material component according to weight percentage, when the acid used is hydrochloric acid, formic acid or acetic acid, first dilute the acid, and then add it to water; when the acid When it is a biological acid, it does not need to be diluted, and it can be directly added to water. After stirring, sequentially add alkyl quaternary ammonium salt, sodium ascorbate, emulsion corrosion inhibitor, citric acid, and drainage aid, and stir for 2-5 minutes to prepare low Viscosity reduction slippery water acid.

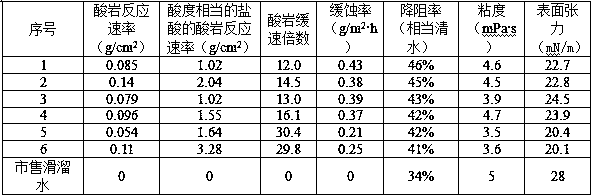

[0036] The specific implementation formula of described low-viscosity drop resistance slippery water acid solution is as follows:

[0037] 1. A low-viscosity drop-resistance slick water acid solution, consisting of the following raw material components in weight percent (total amount 100%): hydrochloric acid 5%, dodecyltrimethylammonium ch...

Embodiment 2

[0051] 1. A method for volumetric acid fracturing of a carbonate reservoir fracture network, comprising the following steps:

[0052] (1) Inject low-viscosity slick water acid fluid, and add proppant for slugging, the number of slugging is not less than 3 times, and carry out fracture network volume fracturing reconstruction for micro-fractures in the reservoir;

[0053] (2) Inject water-based sand-carrying fracturing fluid to form sand-filled fractures with a fracture length of not less than 120 meters on both sides of the wellbore;

[0054] (3) Inject displacement fluid, shut down the well for 0.5h, and then open the well to drain the fluid and test the oil and gas production;

[0055] Wherein, the low-viscosity-reducing slippery water acid solution described in step (1) is composed of the following raw material components in weight percentage: acid 5-20%, alkyl quaternary ammonium salt 1-3%, sodium ascorbate 0.5-2% , emulsion corrosion inhibitor 0.1-0.5%, citric acid 0.5-1...

Embodiment 3

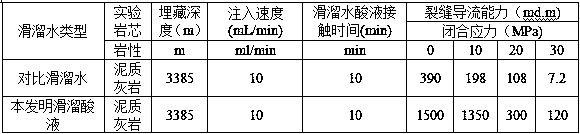

[0066] Well Y is a Permian carbonate rock gas test well in a certain block. The lithology of the acid fracturing section is white calcite fracture filled limestone. MPa / 100m, permeability 0.1-0.4mD, porosity 5.81-6.8%, core acid erosion test found that the core acid erosion rate is greater than 95%, from the perspective of core physical properties, mainly limestone and a small amount of calcite and mud , reacts violently with dilute hydrochloric acid, the sediment is muddy, and the cracks are relatively developed.

[0067] The acid fracturing scheme design and on-site construction were carried out by adopting the volumetric acid fracturing reconstruction method of carbonate reservoir fracture network provided by this patent.

[0068] The specific implementation method is:

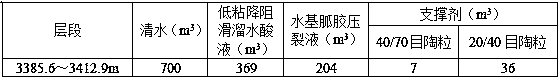

[0069] 1. Construction scale

[0070] See Table 2.

[0071] Table 2 Construction scale and parameters

[0072]

[0073] 2. Low-viscosity slippery water acid formula

[0074] A low-viscosity drop-res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com