High-polymer curing resin of coating agent for drilling fluid

A technology of curing resin and coating agent, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as being unsuitable for mass production, lack of temperature-resistant and salt-resistant groups, low effective production capacity, etc. The coating has obvious inhibitory effect, excellent anti-salt and anti-calcium properties, and the effect of prolonging the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

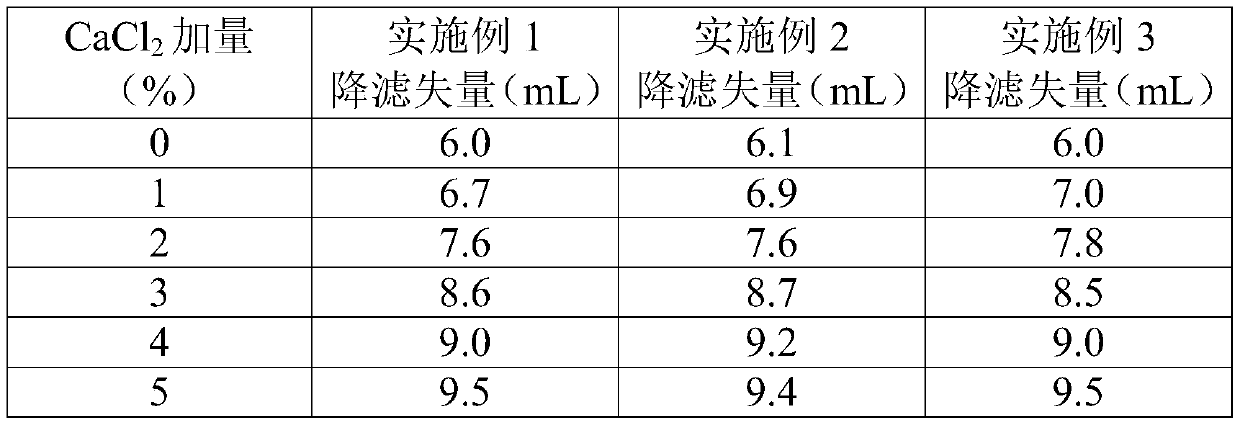

[0018] Embodiment 1: the coating agent macromolecule solidified resin for drilling fluid of the present invention is made from the raw material of following mass parts (mass proportion): 800 parts of clear water, 100 parts of plant gums, 0.5 part of catalyzer, 0.25 parts of initiator, 80 parts of 2-acrylamido-2-methylpropanesulfonic acid, 30 parts of N,N-dimethylacrylamide, 10 parts of 4-vinylpyridine, pH regulator, the amount should meet the adjustment Requirements of the pH value of the back solution (reaction solution) (pH adjuster consumption can be 5 parts), 5 parts of talcum powders, 3 parts of calcium carbonate; Above-mentioned plant gum is water-soluble plant gum selenium gum; Catalyst is that molar concentration is 0.1mol / L sulfuric acid aqueous solution; the initiator is ammonium persulfate-sodium bisulfite system, the mass ratio of ammonium persulfate to sodium bisulfite is 3:1; the pH regulator is analytically pure sodium hydroxide.

[0019] The preparation method ...

Embodiment 2

[0020] Embodiment 2: the coating agent macromolecular solidified resin for drilling fluid of the present invention is made by the raw material of following mass fraction: 1000 parts of clear water, 110 parts of plant gums, 0.8 part of catalyst, 0.5 part of initiator, 100 parts of 2-acrylamido-2-methylpropanesulfonic acid, 40 parts of N, N-dimethylacrylamide, 15 parts of 4-vinylpyridine, pH adjuster, its consumption should satisfy the adjusted solution (reaction solution ) pH value requirement (pH adjuster consumption can be 7 parts), 7 parts of talcum powder, 5 parts of calcium carbonate; Above-mentioned plant gum is water-soluble plant gum guar gum; Catalyst is the sulfuric acid that molar concentration is 0.1mol / L aqueous solution; the initiator is a potassium persulfate-sodium bisulfite system, and the mass ratio of potassium persulfate to sodium bisulfite is 3:1; the pH regulator is analytically pure potassium hydroxide.

[0021] The preparation method of described coating...

Embodiment 3

[0022] Embodiment 3: the drilling fluid coating agent macromolecule solidified resin of the present invention is made from the raw material of following mass fraction: 1000 parts of clear water, 120 parts of plant gums, 0.9 part of catalyst, 0.7 part of initiator, 100 parts of 2-acrylamido-2-methylpropanesulfonic acid, 50 parts of N, N-dimethylacrylamide, 18 parts of 4-vinylpyridine, pH adjuster, its consumption should satisfy the adjusted solution (reaction solution ) pH value requirement (pH adjuster consumption can be 8 parts), 3 parts of talcum powder, 4 parts of calcium carbonate; Above-mentioned plant gum is water-soluble plant gum konjac gum; Catalyst is the sulfuric acid that molar concentration is 0.1mol / L aqueous solution; the initiator is a combination of ammonium persulfate-sodium bisulfite system and potassium persulfate-sodium bisulfite system, the mass ratio of the two systems is 1:1, the ratio of ammonium persulfate to sodium bisulfite The mass ratio is 3:1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com