A kind of composite environmental protection waterproof dry powder mortar and preparation method thereof

A kind of dry powder mortar, environmental protection technology, applied in the field of building materials, can solve the problems of bending resistance, compressive strength decrease, cracking, weakening waterproof effect, etc., to improve impermeability and strength, improve compressive strength, strong thickening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of composite environmental protection waterproof dry powder mortar, it comprises steps:

[0040] S100 Mix the corresponding mass parts of cement, spun yarn, kaolin tailings, high-calcium fly ash and steel slag powder in a high-speed mixer, and the mixing temperature is 40°C;

[0041] S200 adding corresponding parts by mass of siloxane-styrene-acrylate copolymer latex powder, modified serpentine fiber and modified waterproof rubber powder into the mixer, and stirring for 3 minutes; and

[0042] S300 Add the corresponding mass parts of dialkyl polysiloxane, magnesium methacrylate, hydroxyethyl methylcellulose and 2-acrylamide-2 methacrylic sodium sulfonate into the mixer and continue stirring for 5 minutes, mixing Uniformly, the composite environmental protection waterproof dry powder mortar is prepared.

[0043] Wherein, the modified serpentine fiber in the step S200, its preparation method comprises steps:

[0044] Calcining the chrysotile...

Embodiment 1

[0054] The modified serpentine fiber and the modified waterproof rubber powder were respectively prepared according to the above preparation method.

[0055] Mix 320 parts of ordinary Portland cement, 80 parts of slag portland cement, 80 parts of fine sand, 120 parts of kaolin tailing sand, 80 parts of high-calcium fly ash, and 20 parts of steel slag fine powder in a high-speed mixer at 40 ° C. ; Weigh 15 parts of siloxane-styrene-acrylate copolymer latex powder, 15 parts of modified serpentine fiber, 10 parts of modified waterproof rubber powder and add in the mixer and stir for 3 minutes at the same temperature; Add 1.5 parts of dialkyl polysiloxane, 5 parts of magnesium methacrylate, 5 parts of hydroxyethyl methylcellulose, and 3 parts of 2-acrylamide-2-methacrylic sodium sulfonate into the mixer and continue stirring for 5 minutes , fully mixed evenly to prepare the composite water-retaining dry powder mortar.

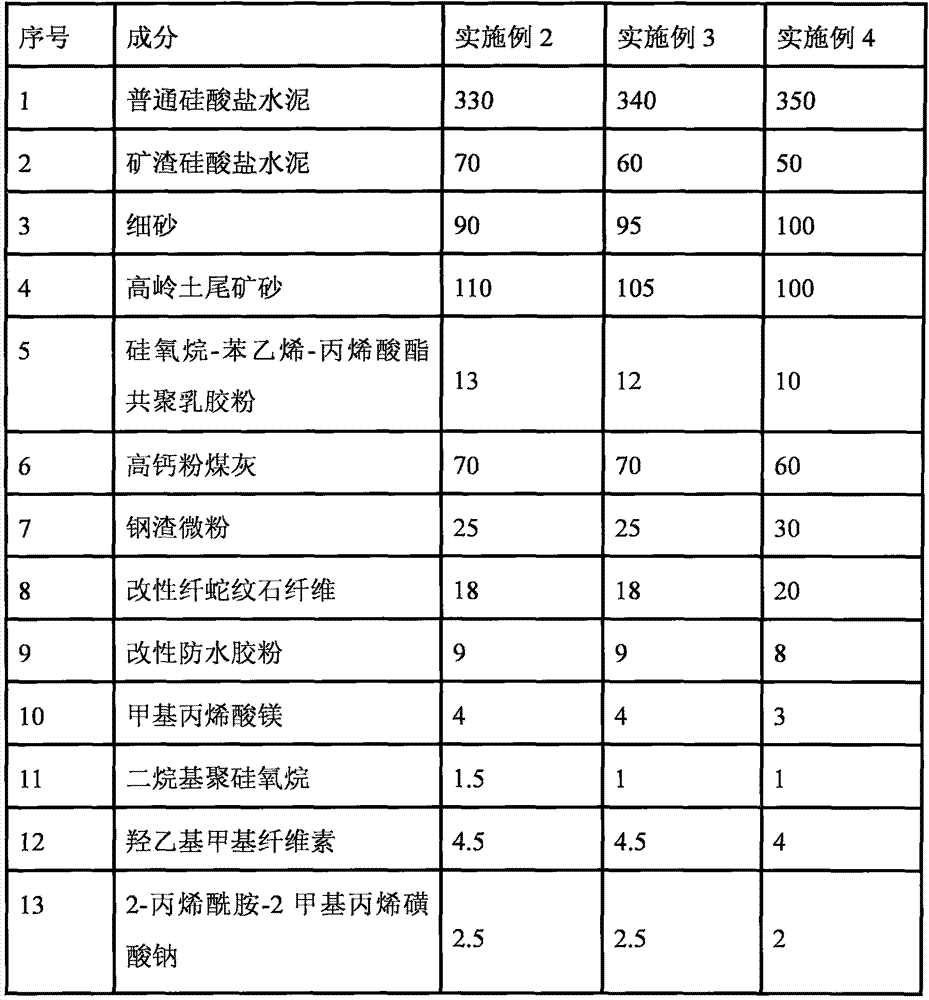

[0056] Embodiment 2, 3, 4: the composition of the mass parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com