Oil well cement retarder with high-temperature controlled-release and delayed-coagulation groups

A technology of retarding group, oil well cement, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of slow development of cement stone strength, inversion of cement stone strength and temperature during thickening time, limited retardation ability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

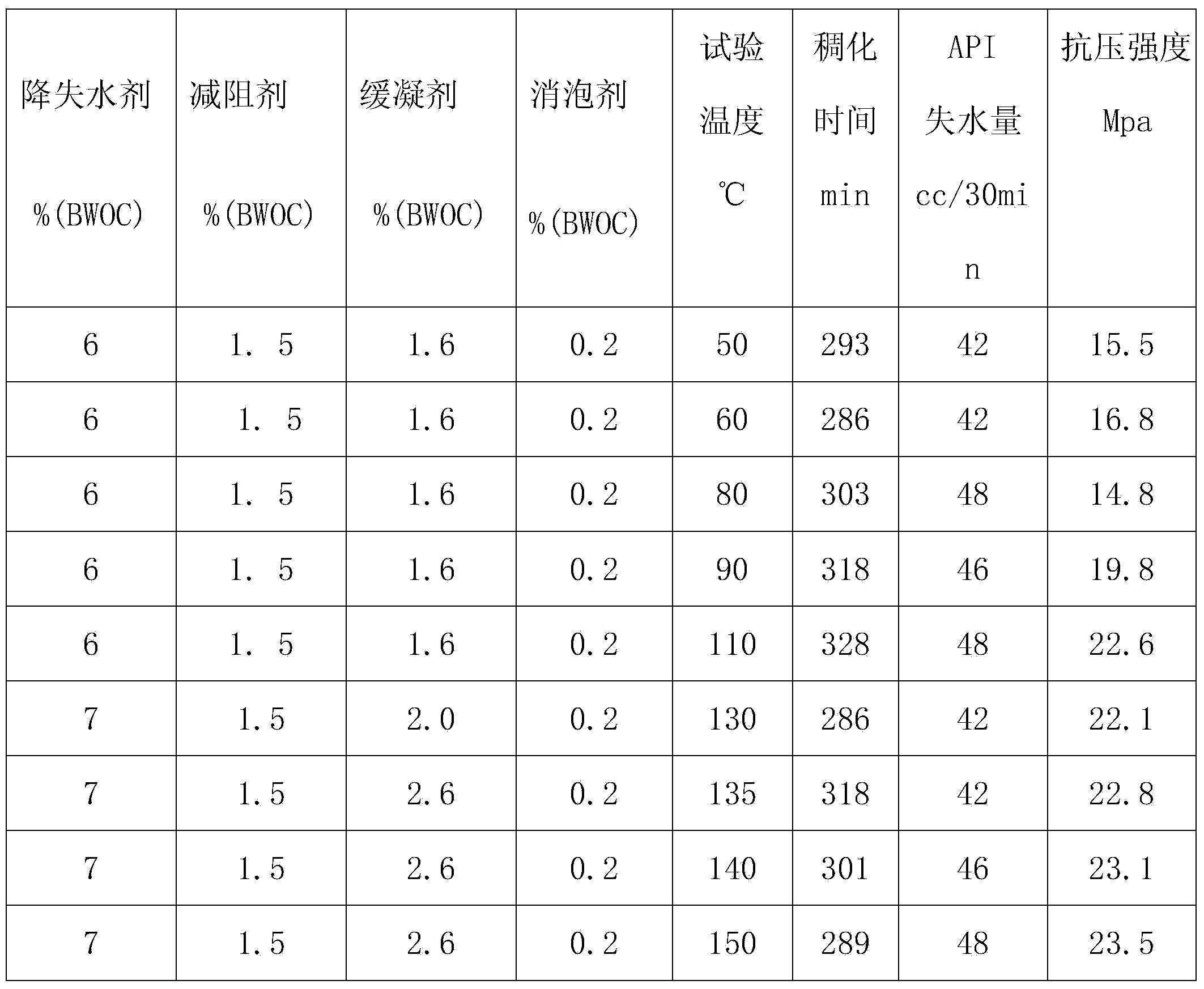

Examples

Embodiment 1

[0028] Carry out the preparation of retarder according to the following main steps:

[0029] Step 1: Weigh four raw materials in molar ratio:

[0030] Itaconic acid: hydroxyethyl methacrylate: ditrimethylolpropane acrylate: 2-acrylamide-2-methylpropanesulfonic acid is 1.0: 2.0: 0.5: 0.1: 8.0;

[0031] Step 2: Add ditrimethylolpropane acrylate into hydroxyethyl methacrylate and fully dissolve;

[0032] Step 3: Calculate the amount of water according to the 10% solution, and add it to the reaction kettle;

[0033] Step 4: Add the solution prepared in step 2, itaconic acid and 2-acrylamide-2-methylpropanesulfonic acid into the reaction kettle, mix and dissolve;

[0034] Step 5: Warm the solution in the reactor to 75°C;

[0035] Step 6: Add ammonium persulfate in an amount of 0.1% of the solution in the reactor, and control the reaction temperature to 75° C. during the reaction; the reaction time is 1.0 hour.

[0036] Step 7: After the reaction is completed, add hydroquinone w...

Embodiment 2

[0038] Carry out the preparation of retarder according to the following main steps:

[0039] Step 1: Weigh four raw materials in molar ratio:

[0040] Itaconic acid: hydroxyethyl methacrylate: ditrimethylolpropane acrylate: 2-acrylamide-2-methylpropanesulfonic acid is 1.5: 3.0: 1.0: 0.5: 10.0;

[0041] Step 2: Add ditrimethylolpropane acrylate into hydroxyethyl methacrylate and fully dissolve;

[0042] Step 3: Calculate the amount of water according to the 28% solution, and add it to the reactor;

[0043] Step 4: Add the solution prepared in step 2, itaconic acid and 2-acrylamide-2-methylpropanesulfonic acid into the reaction kettle, mix and dissolve;

[0044] Step 5: heating the solution in the reactor to 80°C;

[0045] Step 6: Add ammonium persulfate in an amount of 0.2% of the solution in the reactor, and control the reaction temperature to 90° C. during the reaction; the reaction time is 1.5 hours.

[0046] Step 7: After the reaction is completed, add hydroquinone with...

Embodiment 3

[0048] Carry out the preparation of retarder according to the following main steps:

[0049] Step 1: Weigh four raw materials in molar ratio:

[0050] Itaconic acid: hydroxyethyl methacrylate: trimethylolpropane triacrylate: 2-acrylamide-2-methylpropanesulfonic acid is 1.0: 2.0: 0.5: 0.1: 8.0;

[0051] Step 2: Add trimethylolpropane triacrylate into hydroxyethyl methacrylate and fully dissolve;

[0052] Step 3: Calculate the amount of water according to the 10-18% solution, and add it to the reaction kettle;

[0053] Step 4: Add the solution prepared in step 2, itaconic acid and 2-acrylamide-2-methylpropanesulfonic acid into the reaction kettle, mix and dissolve;

[0054] Step 5: Warm the solution in the reactor to 75°C;

[0055] Step 6: Add ammonium persulfate in an amount of 0.1% of the solution in the reactor, and control the reaction temperature to 75° C. during the reaction; the reaction time is 1.0 hour.

[0056]Step 7: After the reaction is completed, add hydroquino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com