Humic acid modified filtrate reducer for water-based drilling fluid and preparation method and drilling fluid

A technology of water-based drilling fluid and fluid loss reducer, applied in the field of water-based drilling fluid, can solve problems such as poor salt resistance and poor temperature resistance, reduce fluid loss, meet environmental protection requirements, and improve filter cake quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

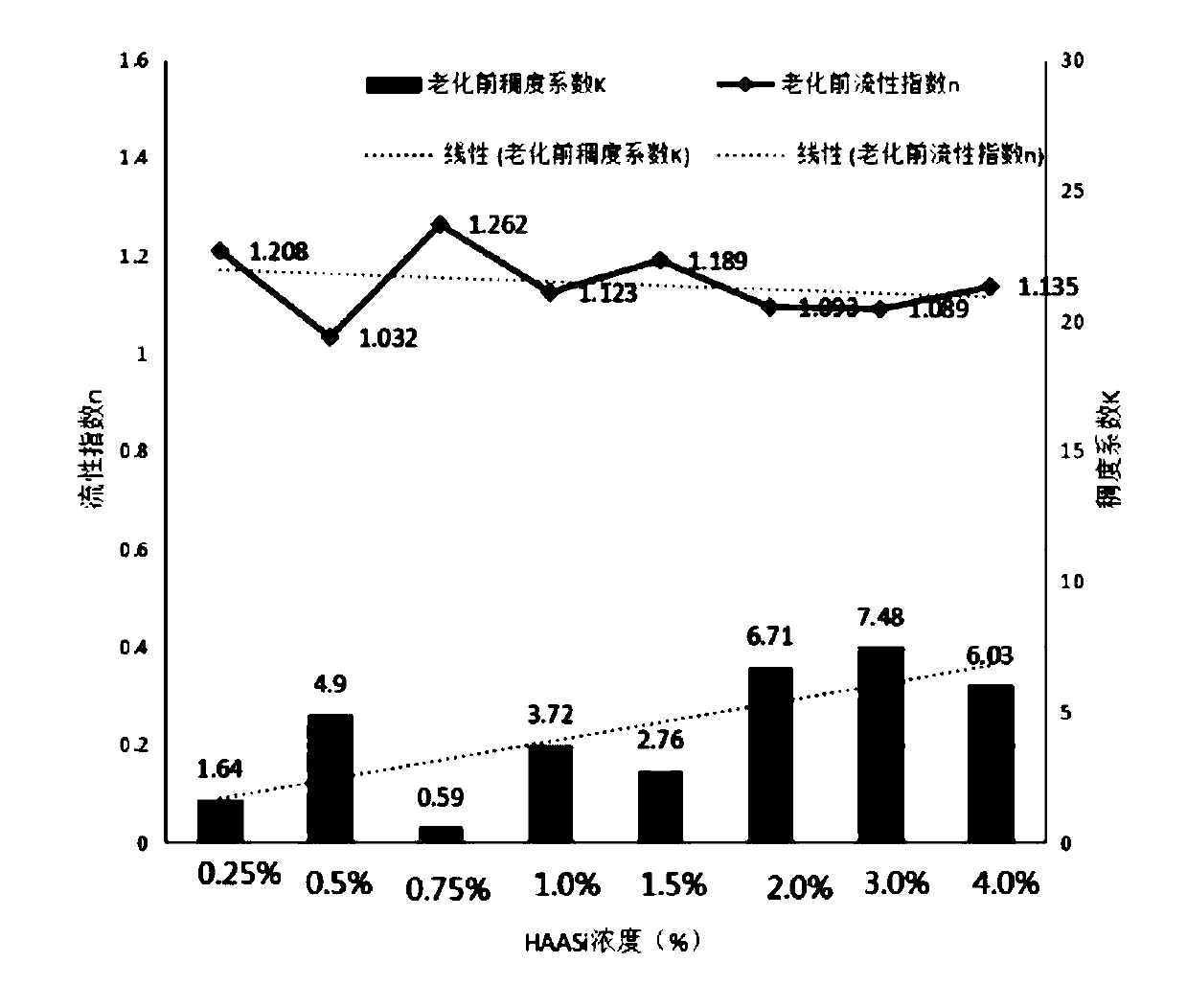

Image

Examples

Embodiment 1

[0069] Preparation of humic acid modified water-based drilling fluid fluid loss control agent:

[0070] (1) Reagent preparation:

[0071] The initiator adopts ammonium persulfate-sodium bisulfite;

[0072] Weigh 10g of modified silica TSP-L12 and dissolve it in 10ml of ethanol, then add 30ml of water to make a solution;

[0073] (2) Weigh 20g of acrylamide, 50g of 2-acrylamido-2-methylpropanesulfonic acid, 30g of sodium humate and 400ml of water into the reaction vessel;

[0074] (3) The solution configured in step (1) is added to the reaction vessel, and stirred and dissolved at a stirring rate of 200 rad / min;

[0075] (4) Use the NaOH solution with a mass fraction concentration of 20% to adjust the pH value of the reaction solution in the reaction vessel to 8; then heat until the temperature of the reaction solution in the reaction vessel is 70° C., then feed nitrogen for 30 minutes, and the feed of nitrogen The rate is 0.2L / min;

[0076] (5) Add 2 g of ammonium persulfa...

Embodiment 2

[0079] Preparation of humic acid modified water-based drilling fluid fluid loss control agent:

[0080] (1) Reagent preparation:

[0081] The initiator adopts ammonium persulfate-sodium bisulfite;

[0082] Weigh 5g of modified silica TSP-L12 and dissolve it in 5ml of ethanol, then add 3ml of water to make a solution;

[0083] (2) Weigh 25g of acrylamide, 50g of 2-acrylamido-2-methylpropanesulfonic acid, 25g of sodium humate and 300ml of water into the reaction vessel;

[0084] (3) The solution configured in step (1) is added to the reaction vessel, and stirred and dissolved at a stirring rate of 300 rad / min;

[0085] (4) Use the NaOH solution with a mass fraction concentration of 20% to adjust the pH value of the reaction solution in the reaction vessel to 7; then heat until the temperature of the reaction solution in the reaction vessel is 60°C-80°C, then feed nitrogen into the nitrogen for 25min The feeding rate is 0.3L / min;

[0086] (5) Add 3 g of ammonium persulfate-so...

Embodiment 3

[0089] Preparation of humic acid modified water-based drilling fluid fluid loss control agent:

[0090] (1) Reagent preparation:

[0091] The initiator adopts potassium persulfate;

[0092] Weigh 10g of modified silica TSP-L12 and dissolve it in 10ml of ethanol, then add 30ml to make a solution;

[0093] (2) Weigh 40g of acrylamide, 30g of 2-acrylamido-2-methylpropanesulfonic acid, 30g of sodium humate and 400ml of water into the reaction vessel;

[0094] (3) The solution configured in step (1) is added to the reaction vessel, and stirred and dissolved at a stirring rate of 100 rad / min;

[0095] (4) Use the NaOH solution with a mass fraction concentration of 20% to adjust the pH value of the reaction solution in the reaction vessel to 9; then heat until the temperature of the reaction solution in the reaction vessel is 80° C., then feed nitrogen into the nitrogen for 35min. 0.3L / min;

[0096] (5) Add 2 g of potassium persulfate into the reaction vessel under a nitrogen atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com