Concrete water-reducing agent with high pressure resistance as well as preparation method thereof

A technology of concrete water reducing agent and defoaming agent, which is applied in the field of construction accessories, can solve the problems of easy slump, lack of resistance to pressure, resistance to pressure difference, etc., to improve fluidity, strengthen modification effect, high The effect of slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

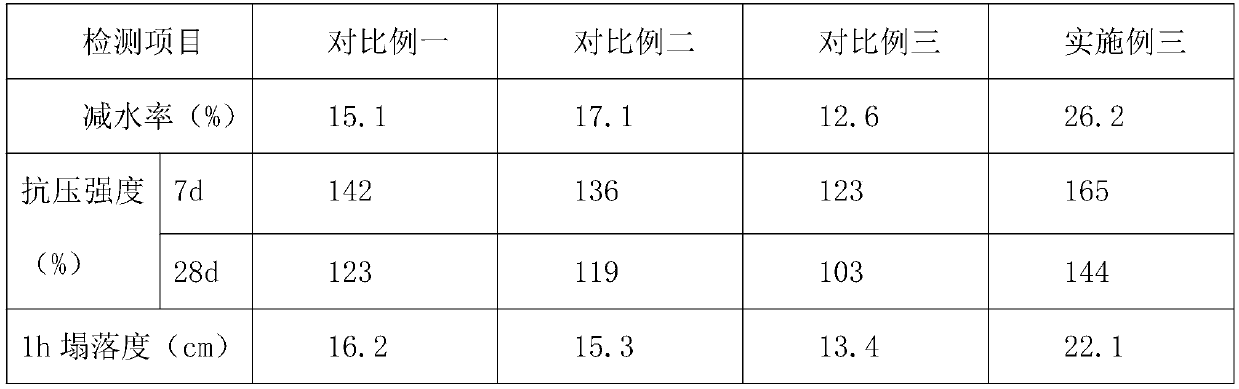

Examples

Embodiment 1

[0017] A compressive and strong concrete water reducer, comprising the following raw materials in parts by weight: 20 parts of methacrylic alcohol polyoxyethylene ether, 8 parts of fatty acid potassium soap, 3 parts of sodium methacrylic acid sulfonate, and 5 parts of bone glue , 2 parts of sodium tripolyphosphate, 2 parts of cocoyl diethanolamine, 1 part of shell powder, 2 parts of methacrylic polyethylene glycol, 1 part of supersaturated urea solution, 8 parts of melamine formaldehyde resin, 3 parts of defoamer , 2 parts of thickener, 1 part of mercaptoacetic acid, 10 parts of deionized water.

[0018] The molecular weight of the methacrylic alcohol polyoxyethylene ether is 2000.

[0019] The defoaming agent is emulsified silicone oil; the thickening agent is aluminum silicate.

[0020] A method for preparing the compressive and strong concrete water reducer, the steps are as follows: S1: Add methacrylic alcohol polyoxyethylene ether, fatty acid potassium soap, sodium methacrylic ...

Embodiment 2

[0024] A compressive and strong concrete water reducer, comprising the following raw materials in parts by weight: 23 parts of methacrylic alcohol polyoxyethylene ether, 10 parts of fatty acid potassium soap, 5 parts of sodium methacrylate sulfonate, and 7 parts of bone glue , 3 parts of sodium tripolyphosphate, 3 parts of cocoyl diethanolamine, 2 parts of shell powder, 4 parts of methacrylic polyethylene glycol, 2 parts of supersaturated urea solution, 10 parts of melamine formaldehyde resin, 4 parts of defoamer , 4 parts thickener, 2 parts mercaptoacetic acid, 13 parts deionized water.

[0025] The molecular weight of the methacrylic alcohol polyoxyethylene ether is 2,100.

[0026] The defoaming agent is emulsified silicone oil; the thickening agent is aluminum silicate.

[0027] A method for preparing the compressive and strong concrete water reducer, the steps are as follows: S1: Add methacrylic alcohol polyoxyethylene ether, fatty acid potassium soap, sodium methacrylic sulfona...

Embodiment 3

[0031] A compression-resistant and strong concrete water reducer, comprising the following raw materials in parts by weight: 26 parts of methacrylic alcohol polyoxyethylene ether, 12 parts of fatty acid potassium soap, 6 parts of sodium methacrylate sulfonate, and 8 parts of bone glue , 4 parts of sodium tripolyphosphate, 3.5 parts of cocoyl diethanolamine, 3 parts of shell powder, 5 parts of methacrylic polyethylene glycol, 3 parts of supersaturated urea solution, 13 parts of melamine formaldehyde resin, 4.5 parts of defoamer , 6 parts thickener, 3 parts mercaptoacetic acid, 16 parts deionized water.

[0032] The molecular weight of the methacrylic alcohol polyoxyethylene ether is 2,200.

[0033] The defoaming agent is emulsified silicone oil; the thickening agent is aluminum silicate.

[0034] A method for preparing the compressive and strong concrete water reducer, the steps are as follows: S1: Add methacrylic alcohol polyoxyethylene ether, fatty acid potassium soap, sodium metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com