Gel packing material and preparation method thereof

A technology of jelly and raw materials, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor gel breaking performance and poor temperature resistance, so as to increase the strength of jelly, improve stability and toughness, and form The effect of shortening the glue time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

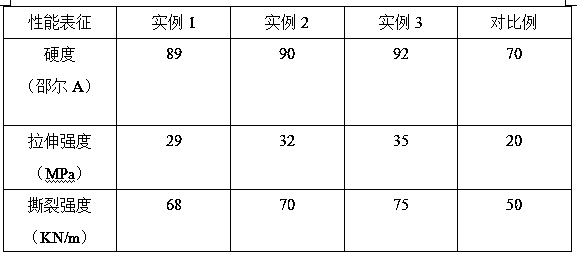

Examples

Embodiment Construction

[0023] Take 500-600g of rice husk ash, add 1.5-3.0L of 20% sodium hydroxide solution, stir at 300-400r / min for 2-3 hours in a constant temperature water bath at 90-100°C, then filter, collect the filtrate, and The filtrate is evaporated and concentrated on a rotary evaporator until the solid content is 40-50%, to obtain a weighting agent, take 40-80g acrylamide, 20-40g sodium methacrylate, 15-30g 2-acrylamido-2-methylpropane Add sulfonic acid to 300-500mL deionized water, stir at 300-400r / min at 18-20°C for 20-30min, and adjust the pH to 7.0-7.5 with sodium carbonate solution to obtain a reaction solution. Take 50-100g of alkali lignin, Add 300-500mL of deionized water, stir at 300-400r / min for 10-20min, then add 2-10g of cross-linking agent, mix well and add the reaction solution, under nitrogen atmosphere, stir and heat at 200-300r / min to 60 ~80°C, heat preservation reaction for 1~2h, then add 5~10g toughening agent, 0.2~0.5g composite initiator, 1.2~2.4g inhibitor, 120~240g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com