Preparation method for anion chitosan-based flocculant

A technology of chitosan and flocculants, which is applied in the field of preparation of anionic chitosan-based flocculants, can solve problems such as complex preparation processes, and achieve the effects of simple operation, high production efficiency, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

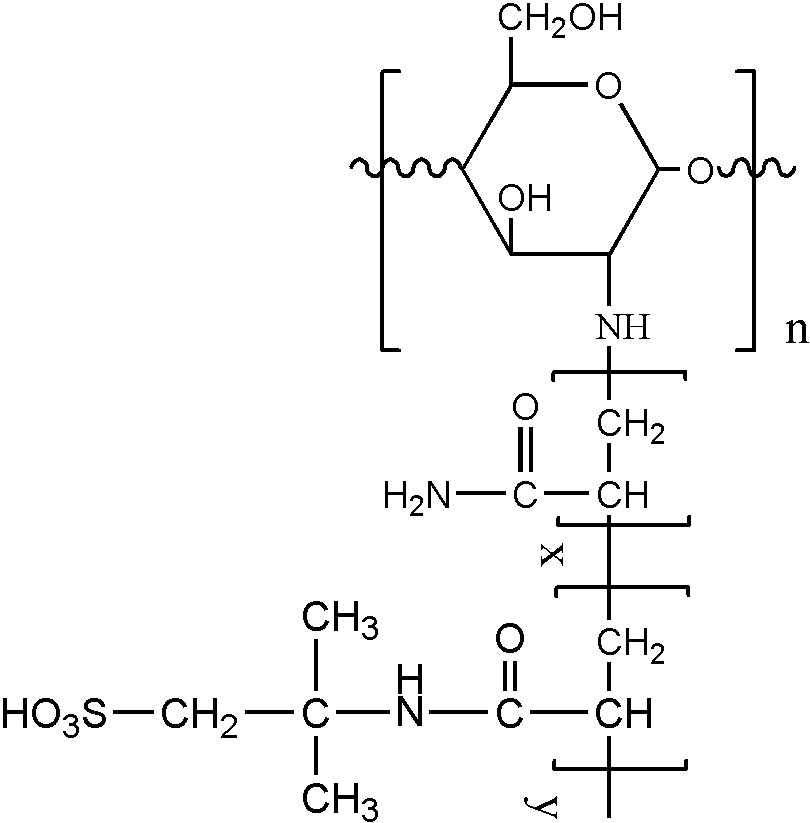

Image

Examples

Embodiment 1

[0026] Anionic chitosan-based flocculants were prepared in the following manner:

[0027] 1) Weigh a certain amount of chitosan and place it in pure water, stir until the chitosan is evenly dispersed, then slowly add glacial acetic acid dropwise into the reactor and continue to stir rapidly, controlling the mass ratio of chitosan to glacial acetic acid to be 2 : 1; after the chitosan was completely dissolved, a chitosan solution with a concentration of 3.5% was obtained.

[0028] 2) Add 4.5:1 AM and AMPS monomers into the reactor and continue to stir until the two are completely dissolved. Control the total mass fraction of chitosan, AM and AMPS in pure water to 40%. Chitosan and AM The mass ratio of the sum of AMPS and AMPS is 1:2.

[0029] 3) Feed N into the reactor 2 Oxygen was driven for 15 min, and at the same time, 3 mL of cerium ammonium nitrate initiator with a concentration of 0.1 mol / L was added at 10 min.

[0030] 4) Stir the reactor for 5 minutes under anaerobic...

Embodiment 2

[0032] Anionic chitosan-based flocculants were prepared in the following manner:

[0033] 1) Weigh a certain amount of chitosan and place it in pure water, stir until the chitosan is evenly dispersed, then slowly add glacial acetic acid dropwise into the reactor and continue to stir rapidly to control the mass ratio of chitosan to glacial acetic acid to 1.5 : 1; after the chitosan is completely dissolved, a chitosan solution with a concentration of 4% is obtained.

[0034] 2) Add 5:1 AM and AMPS monomers into the reactor and continue to stir until the two are completely dissolved. Control the total mass fraction of chitosan, AM, and AMPS in pure water to 40%. Chitosan and AMPS The mass ratio of the sum of AM and AMPS is 1:2.

[0035] 3) Feed N into the reactor 2 Oxygen was driven for 15 min, and at the same time, 2 mL of cerium ammonium nitrate initiator with a concentration of 0.1 mol / L was added at 10 min.

[0036] 4) Stir the reactor for 5 minutes under anaerobic conditi...

Embodiment 3

[0038] Anionic chitosan-based flocculants were prepared in the following manner:

[0039] 1) Weigh a certain amount of chitosan and place it in pure water, stir until the chitosan is evenly dispersed, then slowly add glacial acetic acid dropwise into the reactor and continue to stir rapidly, controlling the mass ratio of chitosan to glacial acetic acid to be 2 : 1; after the chitosan was completely dissolved, a chitosan solution with a concentration of 4% was obtained.

[0040]2) Add 8:1 AM and AMPS monomers into the reactor and continue to stir until the two are completely dissolved. Control the total mass fraction of chitosan, AM, and AMPS in pure water to 40%. Chitosan and AMPS The mass ratio of the sum of AM and AMPS is 1:3.

[0041] 3) Feed N into the reactor 2 Oxygen was driven for 15 min, and at the same time, 2 mL of cerium ammonium nitrate initiator with a concentration of 0.1 mol / L was added at 10 min.

[0042] 4) Stir the reactor for 5 minutes under anaerobic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com