Method for preparing grinding aid for cement

A grinding aid and cement technology, which is applied in the field of cement grinding aid production and processing, can solve the problems of low cost and high cost of grinding aid, and achieve the effects of low cost, improved grinding aid performance, and high comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

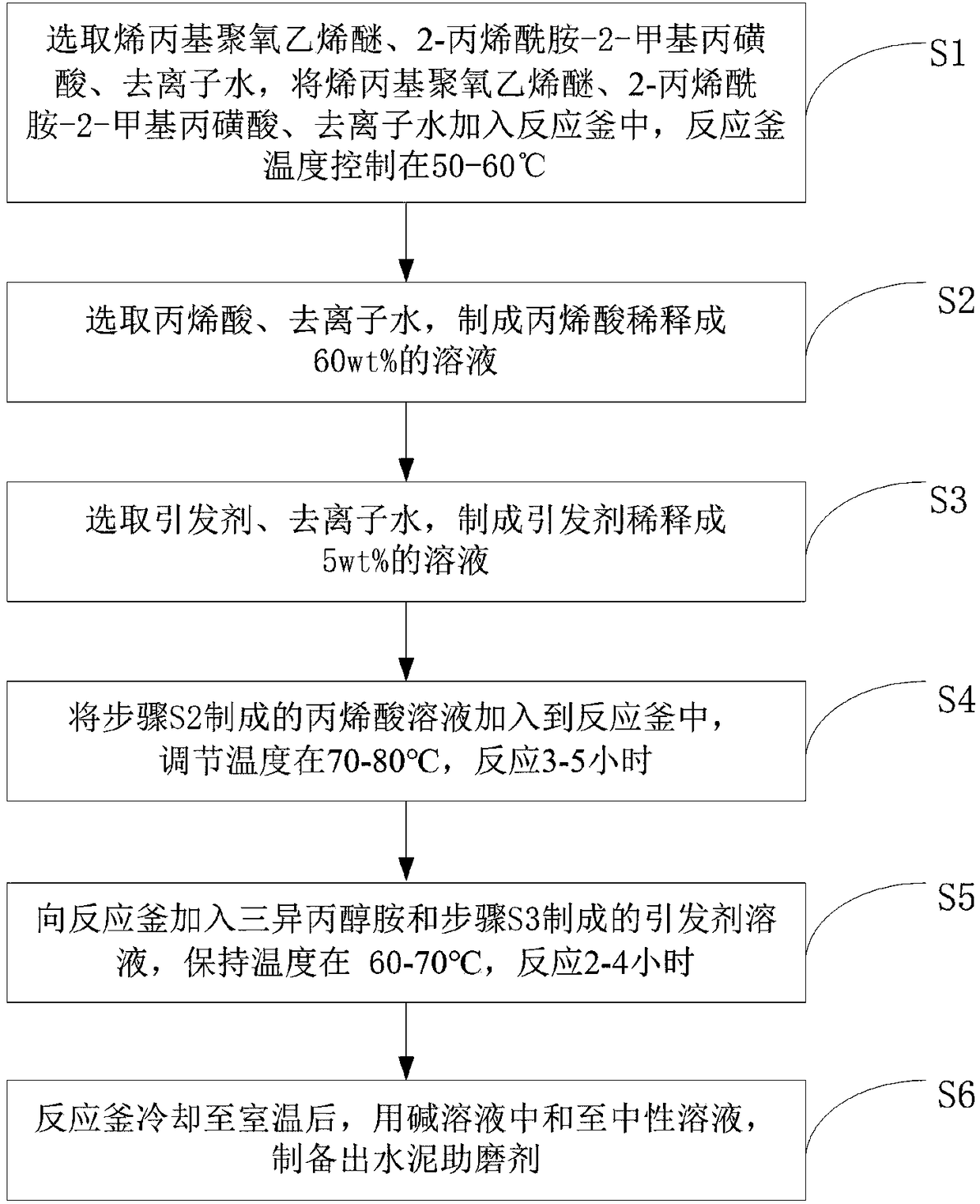

[0025] combine figure 1 , a kind of grinding aid preparation method for cement, comprises the following steps:

[0026] S1. Select allyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, and deionized water, and mix allyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, Deionized water is added to the reactor, and the temperature of the reactor is controlled at 50-60°C; the molar ratio of allyl polyoxyethylene ether to 2-acrylamide-2-methylpropanesulfonic acid is 1:1;

[0027] S2, select acrylic acid and deionized water to make acrylic acid diluted to 60wt% solution;

[0028] S3, choose initiator, deionized water, make the solution that initiator is diluted into 5wt%; Initiator is ammonium persulfate;

[0029] S4. Add the acrylic acid solution prepared in step S2 into the reaction kettle, adjust the temperature at 70-80° C., and react for 3-5 hours;

[0030] S5, adding triisopropanolamine and the initiator solution prepared in step S3 to the...

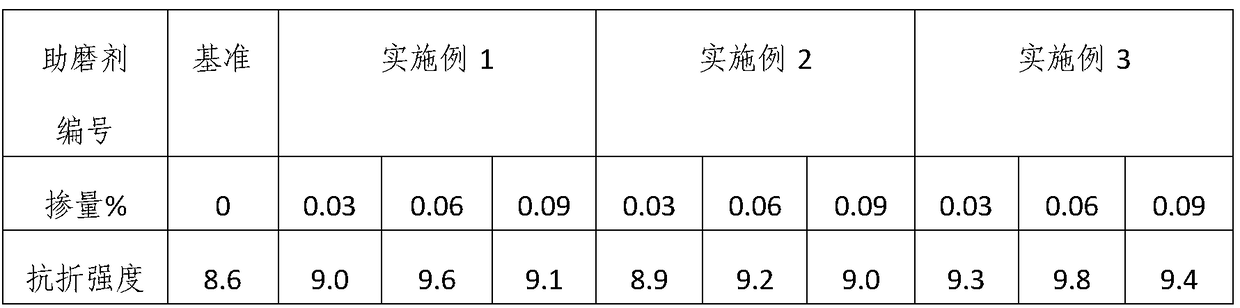

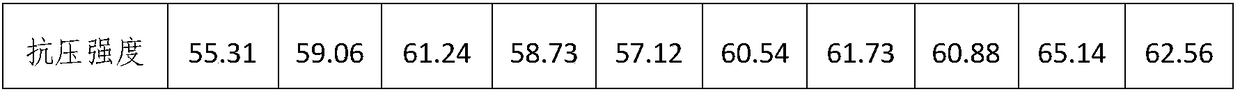

Embodiment 1

[0033] A method for preparing a grinding aid for cement, comprising the following steps:

[0034] S1. Select allyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, and deionized water, mix 1mol allyl polyoxyethylene ether, 1mol 2-acrylamide-2-methylpropanesulfonic acid Add acid and 1L deionized water into the reactor, and control the temperature of the reactor at 50°C;

[0035] S2, choose 1.8mol acrylic acid, deionized water, make the solution that acrylic acid is diluted into 60wt%;

[0036] S3, choose 0.008mol initiator ammonium persulfate, deionized water, make the solution that initiator is diluted into 5wt%;

[0037] S4. Add the acrylic acid solution prepared in step S2 into the reaction kettle, adjust the temperature at 70° C., and react for 5 hours;

[0038] S5, add 0.18mol triisopropanolamine and the initiator ammonium persulfate solution prepared in step S3 to the reactor, keep the temperature at 60°C, and react for 4 hours;

[0039] S6. After the ...

Embodiment 2

[0041] A method for preparing a grinding aid for cement, comprising the following steps:

[0042] S1. Select allyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, and deionized water, mix 1mol allyl polyoxyethylene ether, 1mol 2-acrylamide-2-methylpropanesulfonic acid Acid and 1L deionized water were added to the reactor, and the temperature of the reactor was controlled at 60°C;

[0043] S2, choose 2.4mol acrylic acid, deionized water, make the solution that acrylic acid is diluted to 60wt%;

[0044] S3, choose 0.012mol initiator ammonium persulfate, deionized water, make the solution that initiator is diluted into 5wt%;

[0045] S4. Add the acrylic acid solution prepared in step S2 into the reaction kettle, adjust the temperature at 80° C., and react for 3 hours;

[0046] S5, add 0.24mol triisopropanolamine and the initiator ammonium persulfate solution prepared in step S3 to the reactor, keep the temperature at 70°C, and react for 2 hours;

[0047] S6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com