High performance XNBR vulcanized rubber containing graphene oxide and its preparation method

A vulcanized rubber and high-performance technology, which is applied in the field of preparation of rubber-like polymer composite materials, can solve the problems of not mentioning the application effect of carboxyl nitrile butadiene rubber, no implementation effect, and more reaction steps, etc., so as to improve mechanical strength, The effect of improving the thermal conductivity and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

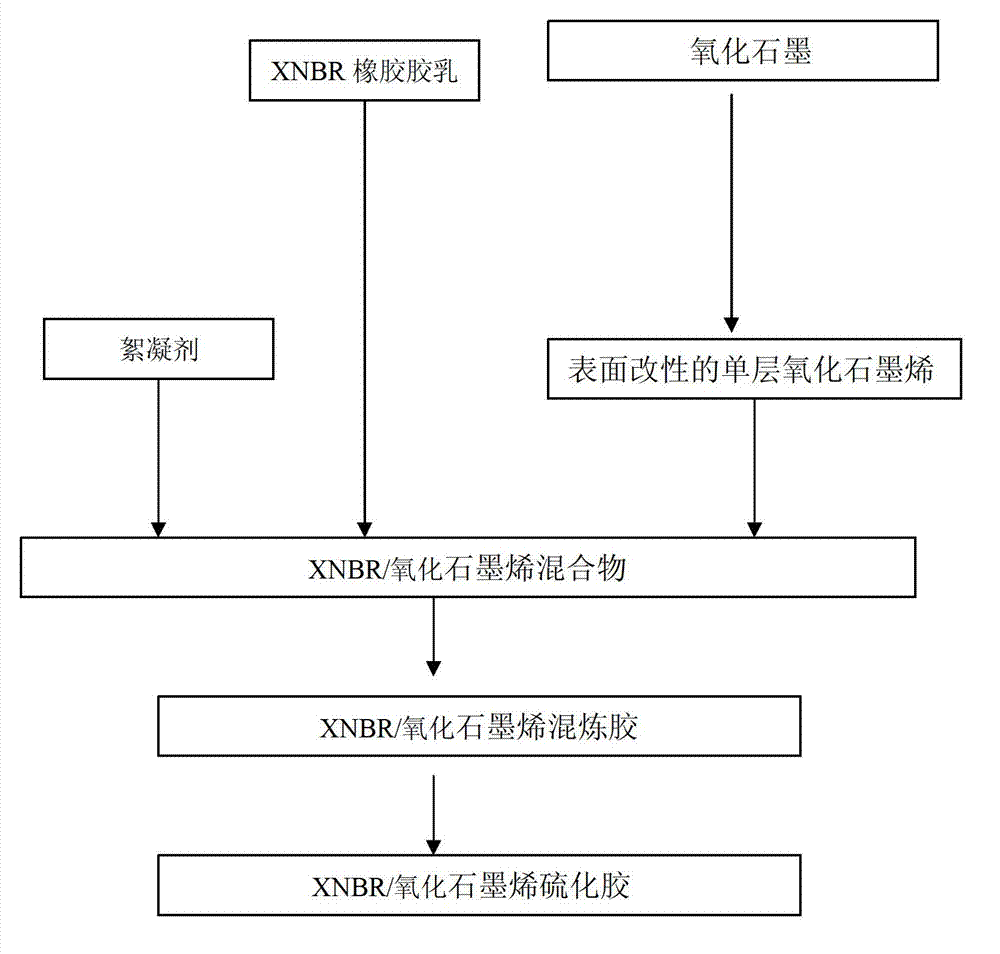

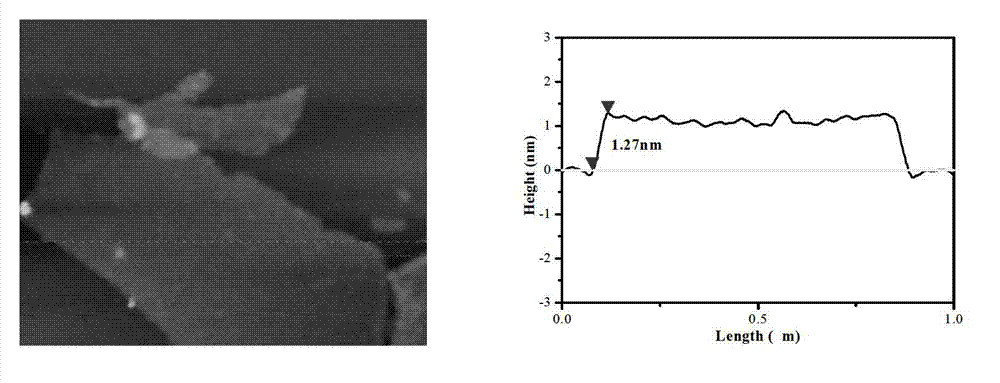

[0021] Weigh 10g of graphene oxide, 50g of sodium lauryl sulfate, and dissolve them in 1L of deionized water. The ultrasonic power is 125W, the temperature is 20°C, ultrasonication is 6h, and the centrifugate in the upper layer is centrifuged at a speed of 6000 rpm. Take the upper liquid to obtain a suspension of graphene oxide with a single-sheet structure. The thickness of graphene oxide see figure 2 .

[0022] Weigh the corresponding mass of single-layer graphene oxide suspension, ultrasonic 20min, weigh 30gXNBR latex, under magnetic stirring, add the graphene oxide solution (the net content of graphene oxide is 0.3g) into the latex, ultrasonic 1h, Add anti-aging agent WL0.15 gram. Adjust the pH value of the latex to about 2, add the latex to the KCl solution for flocculation, then repeatedly wash the flocculated latex with 100° C. deionized water, and dry it at 110° C. for 2 hours. Weigh 10g of graphene / XNBR (masterbatch), add 0.3g of vulcanizing agent DCP, and mix on ...

Embodiment 2

[0024] Repeat the method of Example 1 according to the specified content of each component, but adopt 0.9 gram of graphene oxide in the formula, 0.3 gram of antioxidant WL, 0.3 gram of DTBP, the tensile strength of the vulcanized rubber obtained is 15.61MPa, and the elongation at break The rate is 177%, the 100% modulus is 7.74MPa, the Shore hardness is 77, the maximum thermal decomposition temperature is 473.°C, the thermal conductivity is 0.233W×mK-1, and the thermal diffusivity is 0.096mm 2 ·s -1 . Oil absorption (ASTM1 # Oil) after treatment, the tensile strength is 10.4MPa, the elongation at break is 176%, and the Shore hardness is 73.

Embodiment 3

[0026] Repeat the method of Example 1 according to the specified content of each component, but adopt 1.2 grams of graphene oxide in the formula, 0.15 grams of antioxidant 4010NA, 0.2 grams of DCP, the tensile strength of the vulcanized rubber obtained is 12.9MPa, and the elongation at break The rate is 191%, the 100% modulus is 5.0MPa, the Shore hardness is 77, the maximum thermal decomposition temperature is 473.°C, the thermal conductivity is 0.270W×mK-1, and the thermal diffusivity is 0.096mm 2 ·s -1 . Oil absorption (ASTM1 # ) After treatment, the tensile strength is 12.1MPa, the elongation at break is 191%, and the Shore hardness is 75.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com