A kind of preparation method of gas diffusion layer for proton exchange membrane fuel cell

A gas diffusion layer, proton exchange membrane technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low surface energy, uneven dispersion, and widespread concern of PTFE, and achieve improved electrical conductivity and air permeability. The degree of dispersion and the effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

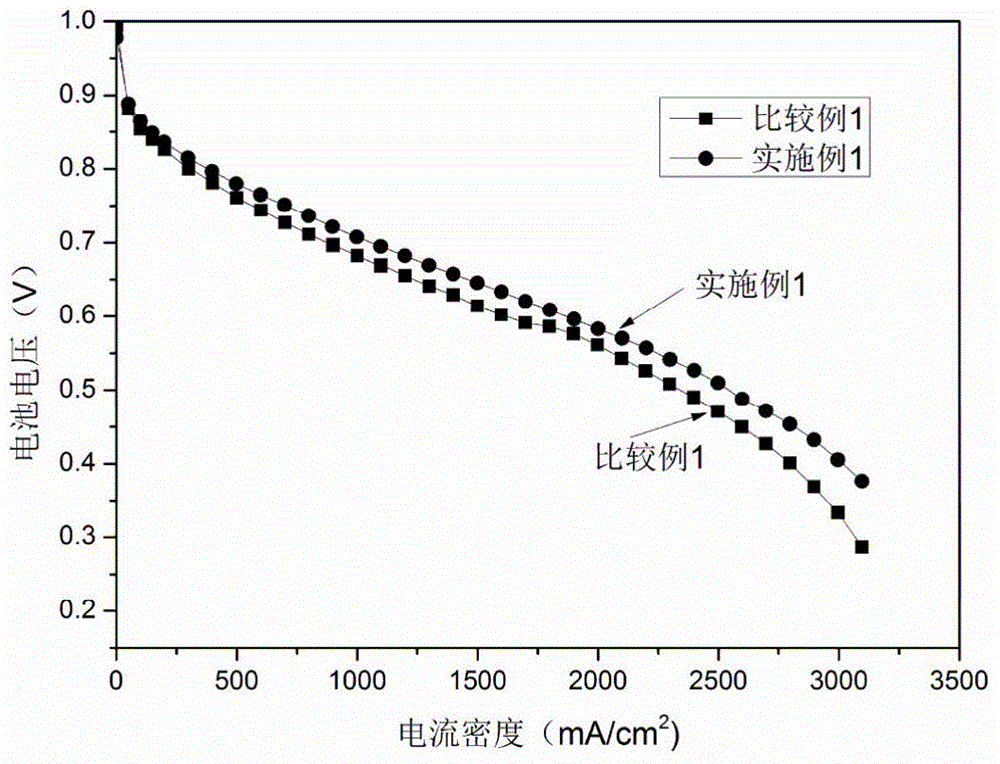

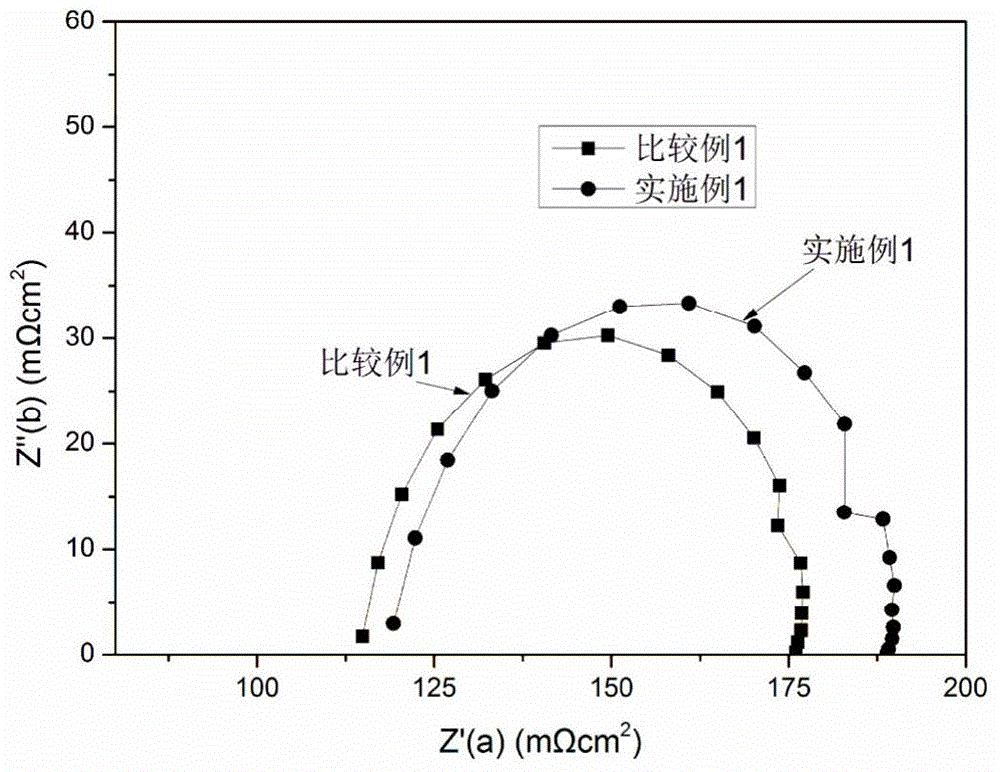

Embodiment 1

[0023] According to the method of the present invention, weigh 60 mg of polyvinylpyrrolidone (PVP) and add it to 70 g of deionized water to form a uniform aqueous solution. Measure 5 ml of the aqueous solution, add 62.5 mg of acetylene black into it, and stir magnetically for 2 hours. The stirrer rotates at 1600 rpm, and then ultrasonically disperses for 30 minutes to form a uniform suspension, and then adds 500 mg of PTFE emulsion (5wt%) to the above suspension, and stirs evenly to obtain a microporous layer slurry. The above microporous layer slurry was evenly coated on one side of Toray carbon paper, dried and weighed, and then this step was repeated until the loading amount of carbon black reached 0.5 mg / cm 2 ; Then spray a low concentration of PTFE emulsion (0.25wt%) on the side of the carbon paper that is not coated with the microporous layer, so that the loading of PTFE reaches 1% of the mass of the carbon paper. Finally, the entire diffusion layer was sintered in a nit...

Embodiment 2

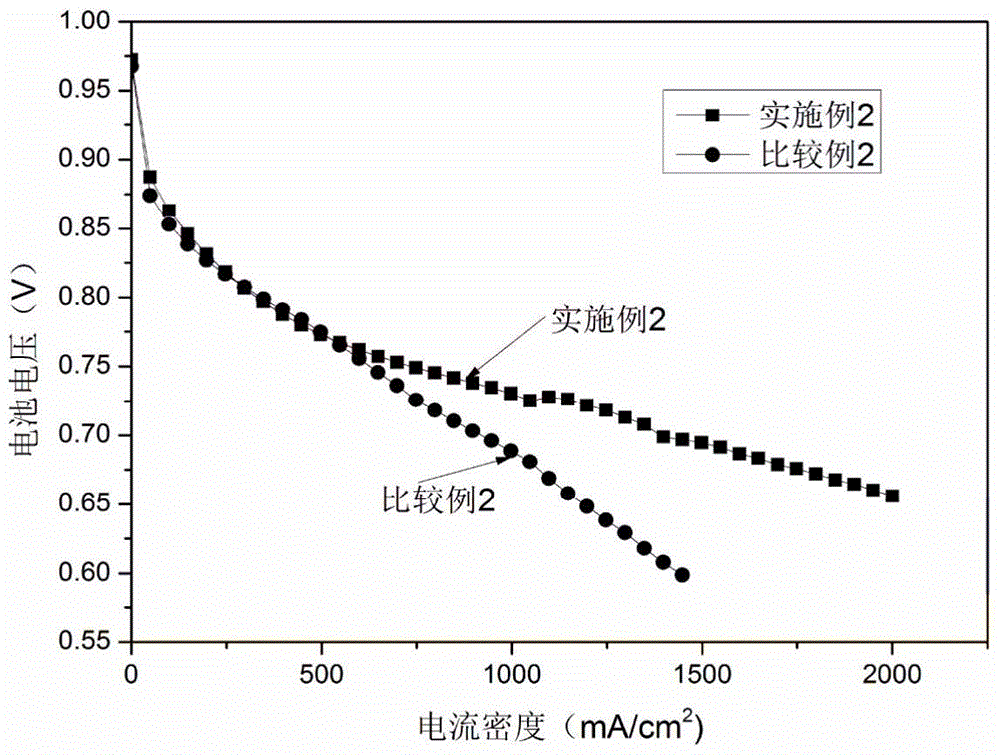

[0028] According to the method of the present invention, weigh 60 mg of polyvinylpyrrolidone (PVP) and add it to 70 g of deionized water to form a uniform aqueous solution. Measure 10 ml of the aqueous solution, add 62.5 mg of acetylene black into it, and stir magnetically for 1 hour. The stirrer rotates at 1600 rpm, and then ultrasonically disperses for 30 minutes to form a uniform suspension, and then adds 500 mg of PTFE emulsion (5wt%) to the above suspension, and stirs evenly to obtain a microporous layer slurry. The above microporous layer slurry was evenly coated on one side of Toray carbon paper, dried and weighed, and then this step was repeated until the loading amount of carbon black reached 0.5 mg / cm 2 ; Then spray a low concentration of PTFE emulsion (0.25wt%) on the side of the carbon paper that is not coated with the microporous layer, so that the loading of PTFE reaches 2% of the mass of the carbon paper. Finally, the entire diffusion layer was sintered in a nit...

Embodiment 3

[0033] According to the method of the present invention, weigh 60 mg of polyvinylpyrrolidone (PVP) and add it to 70 g of deionized water to form a uniform aqueous solution. Measure 10 ml of the aqueous solution, add 120 mg of acetylene black to it, magnetically stir for 5 hours, and stir The rotation speed of the machine was 1600 rpm, and then ultrasonic dispersion was performed for 30 minutes to form a uniform suspension, and then 960 mg of PTFE emulsion (5wt%) was added to the above suspension, and stirred evenly to obtain a microporous layer slurry. The above microporous layer slurry was uniformly coated on one side of three Toray carbon papers (8×8cm), dried and weighed, and then this step was repeated until the loading amount of carbon black on the surface of the three carbon papers reached 0.5 mg / cm 2 Then spray low-concentration PTFE emulsion on the uncoated microporous layer side of the three carbon papers, so that the loading of PTFE reaches 1%, 2%, and 3% of the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com