Patents

Literature

81results about How to "Solve the shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

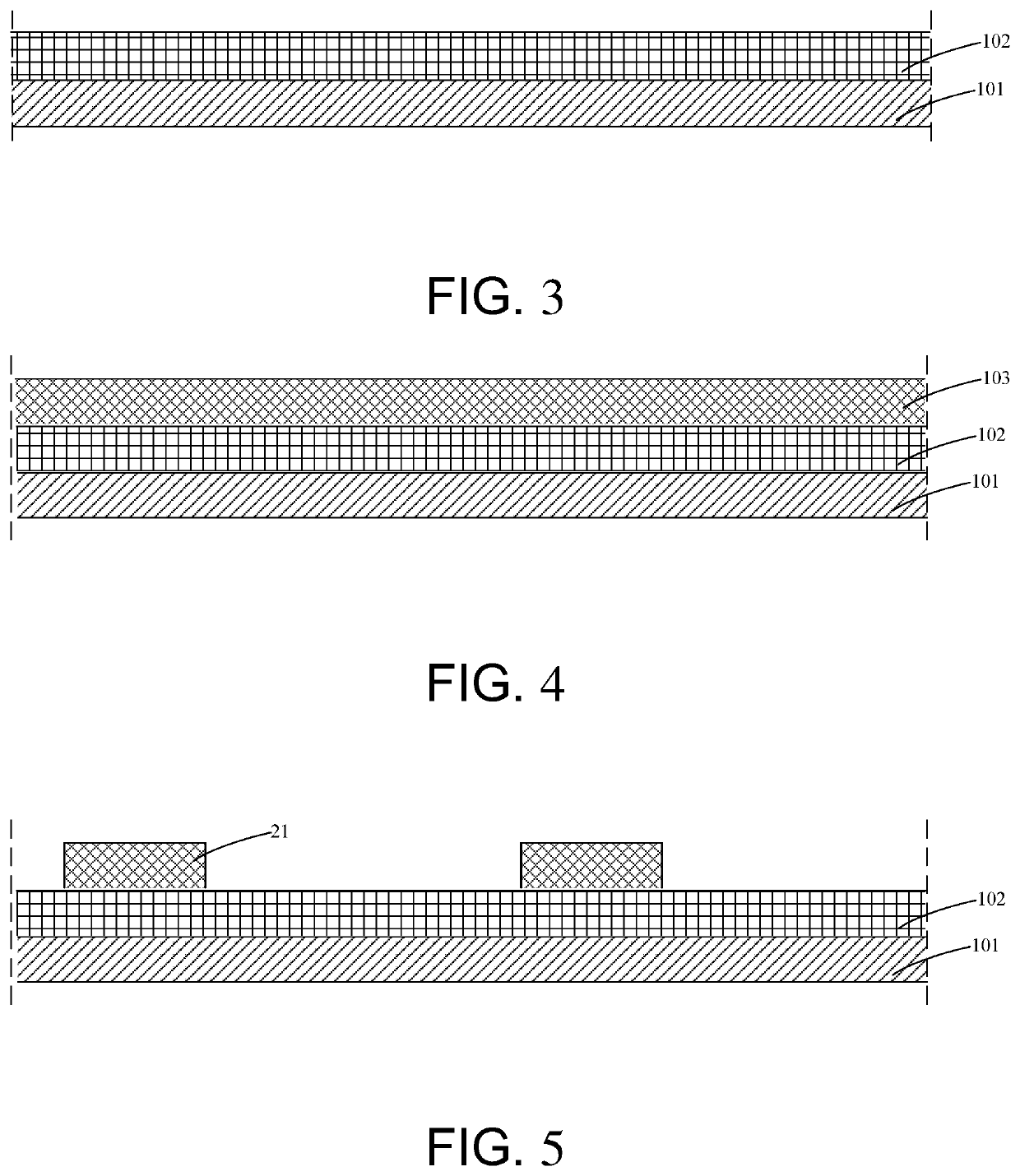

Wafer level fan-out chip packaging method

ActiveCN101604638AAchieve connectionAvoid displacementSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingMetal electrodes

The invention relates to a wafer level fan-out chip packaging method, comprising the following technological processes: a stripping foil and a film dielectric layer I are sequentially covered on the surface of the wafer of a carrier, a photoetching pattern opening I is formed on the film dielectric layer I; a metal electrode and a re-wiring metal routing wire which are connected with a base plate end are arranged on the photoetching pattern opening and the surface thereof, a film dielectric layer II is covered on the surface of the metal electrode, the surface of the re-wiring metal routing wire, and the surface of the film dielectric layer I which are connected with the base plate end, and a photoetching pattern opening II is formed on the film dielectric layer II; a metal electrode connected with a chip end is arranged on the photoetching pattern opening II, after a chip is arranged on the metal electrode connected with the chip end in an inverting way, the injection molding of packaging material and solidification are carried out, so as to form a packaging body with plastic-packaging material; the wafer of the carrier and the stripping foil are separated from the packaging body with plastic-packaging material, so as to form a plastic-packaging wafer; a welding sphere back returns to form a welding ball salient point; cutting is carried out by uniwafers for forming the final structure of the fan-out chip. The method has low cost and a carrying function, and can well solve the problem that the chip is shifted in the technological process.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

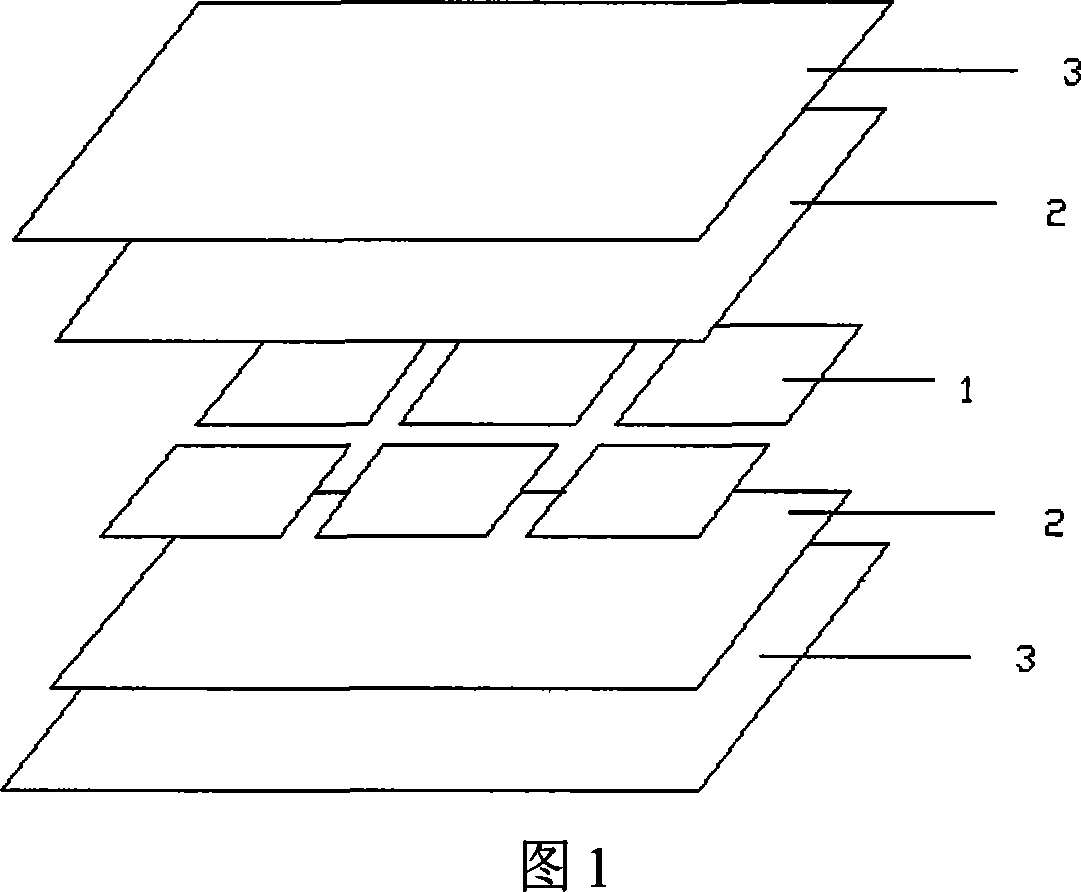

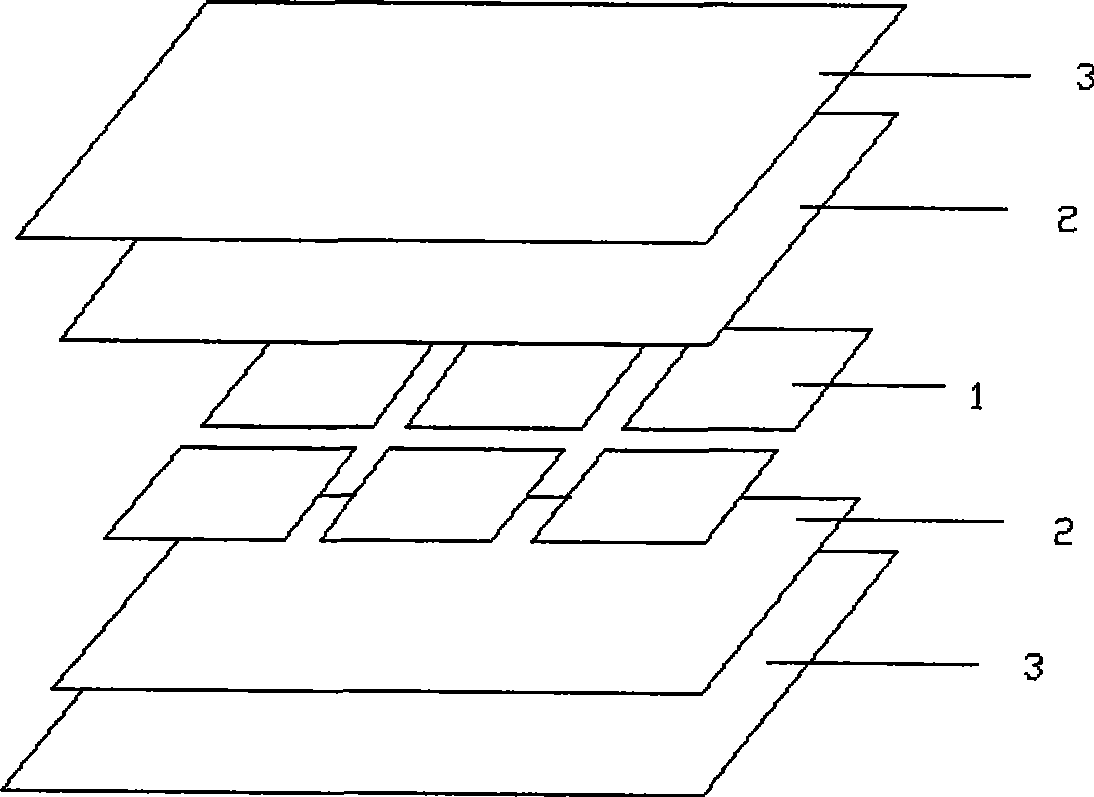

A package method for double-side silicon-glass solar cell assembly

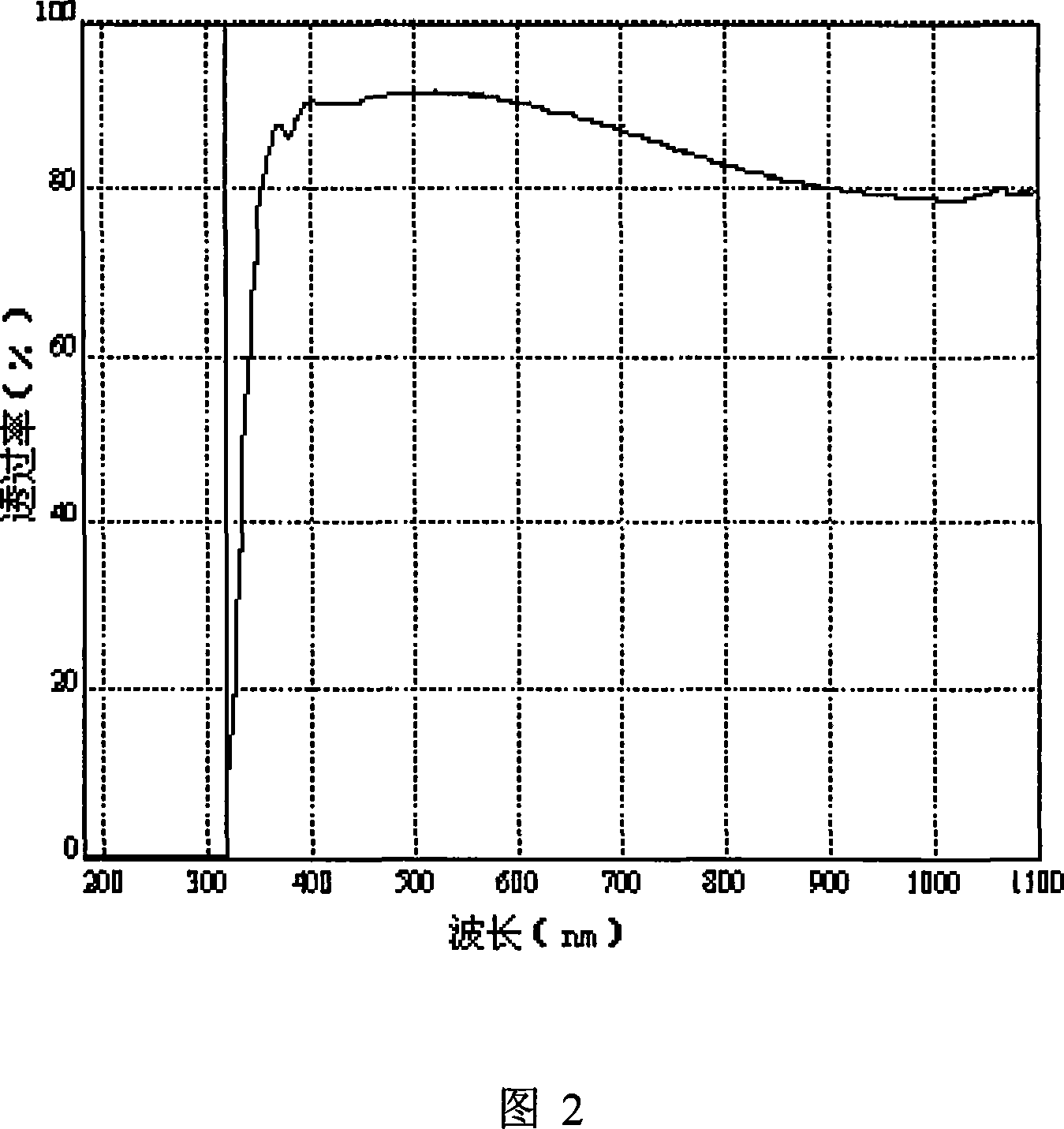

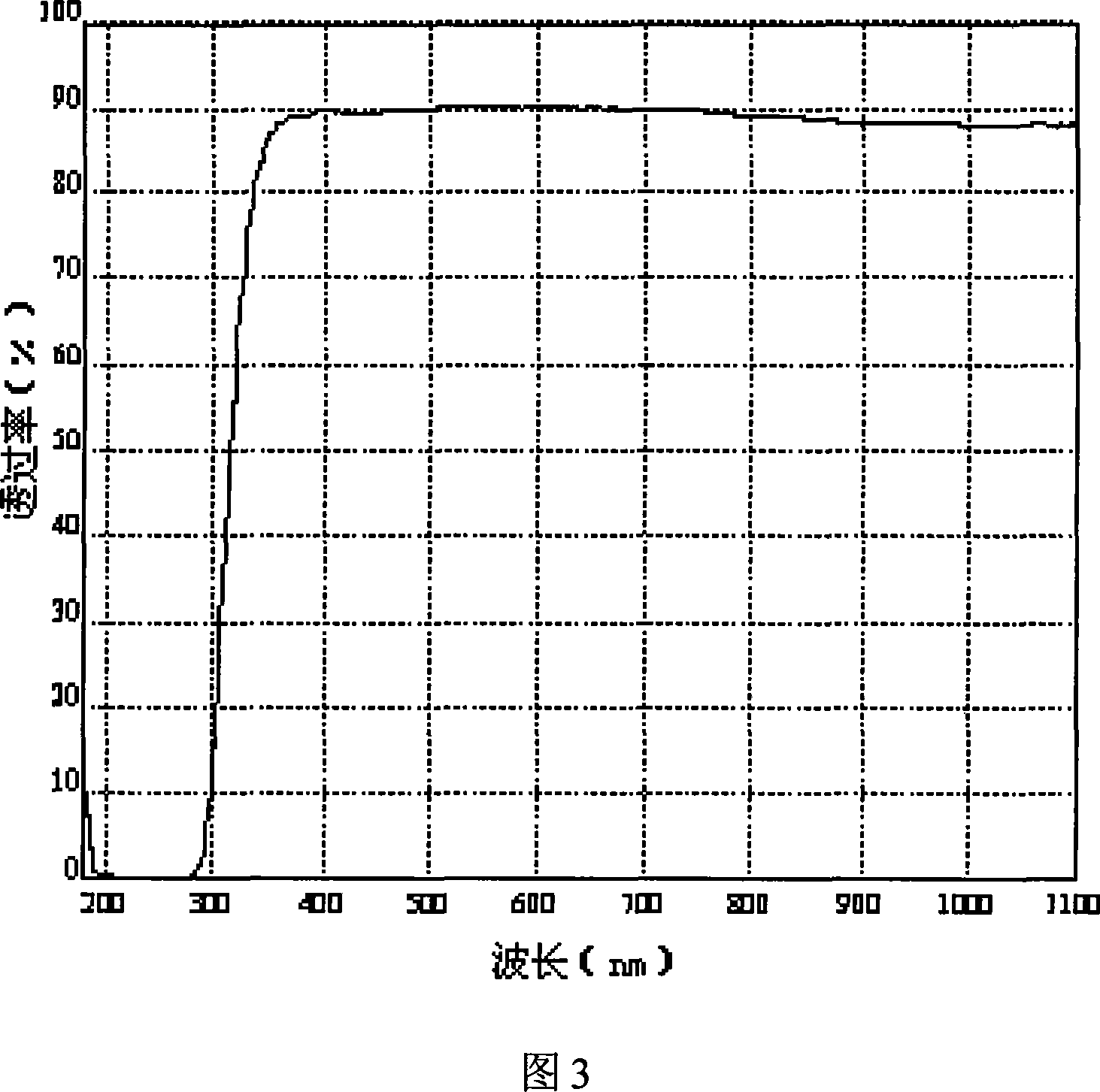

InactiveCN101060146ATo avoidGood effectFinal product manufactureSemiconductor devicesCell layerSilicon solar cell

The related package method for double-face glass crystal silicon solar cell assembly comprises: from top to bottom, stacking a glass-EVA film-solar cell-EVA film-glass structure with the serial solar cell, glass, and EVA film; treating the five-layer structure with special macromolecular material; when heating the cell layer-press machine to 70Deg, putting the five-layer structure into the machine for pressing; setting the machine temperature as 125-145Deg for 15-25min; then, balancing the gas pressure of machine lower cavity with outer atmosphere, and taking out the product. This invention overcomes the damage to product.

Owner:SOUTH CHINA UNIV OF TECH

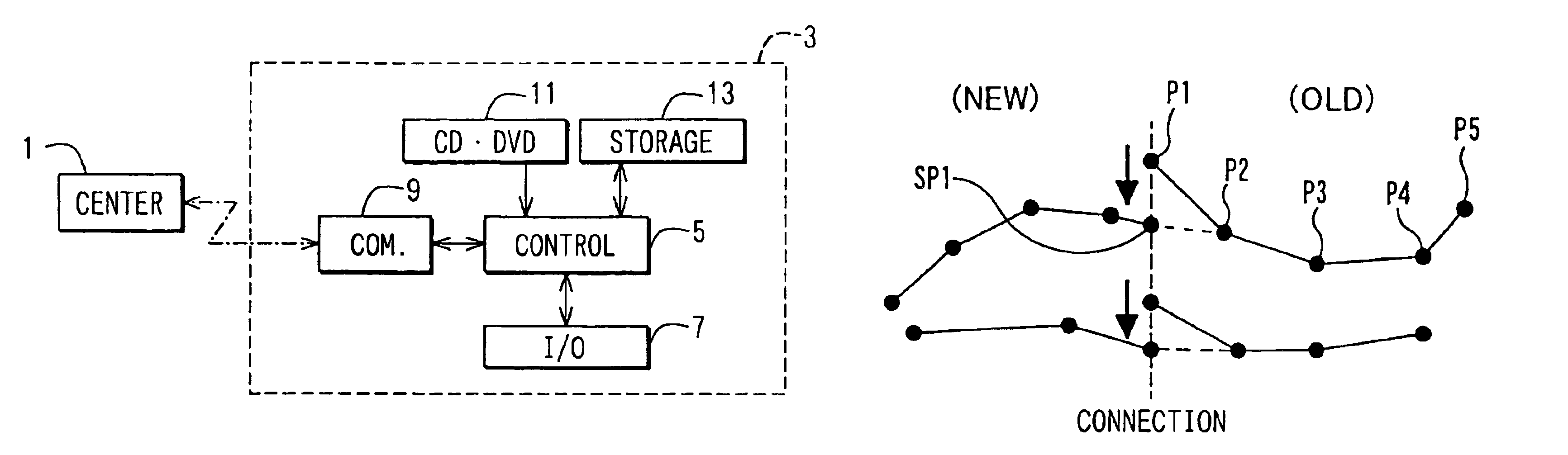

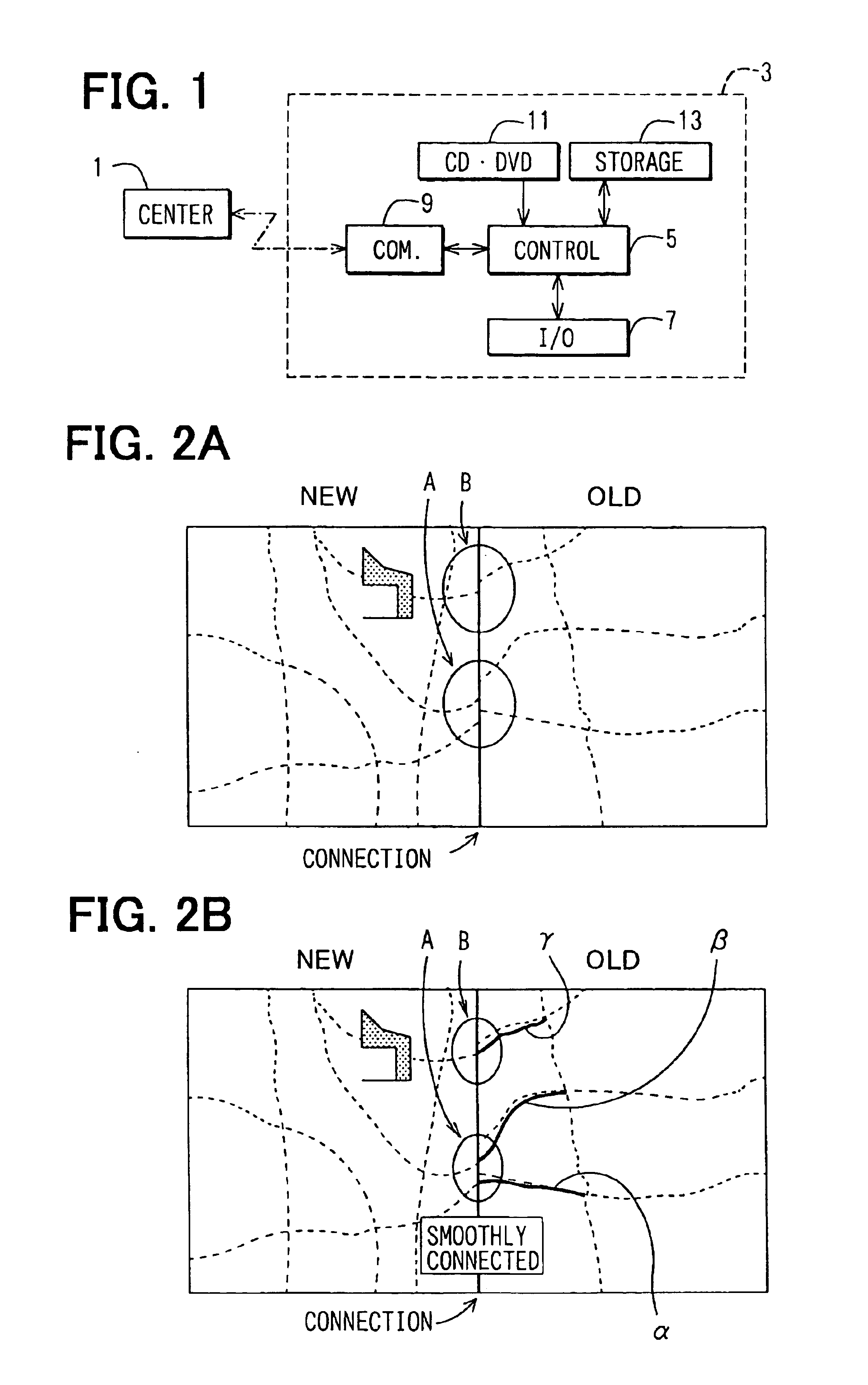

Electronic device and program

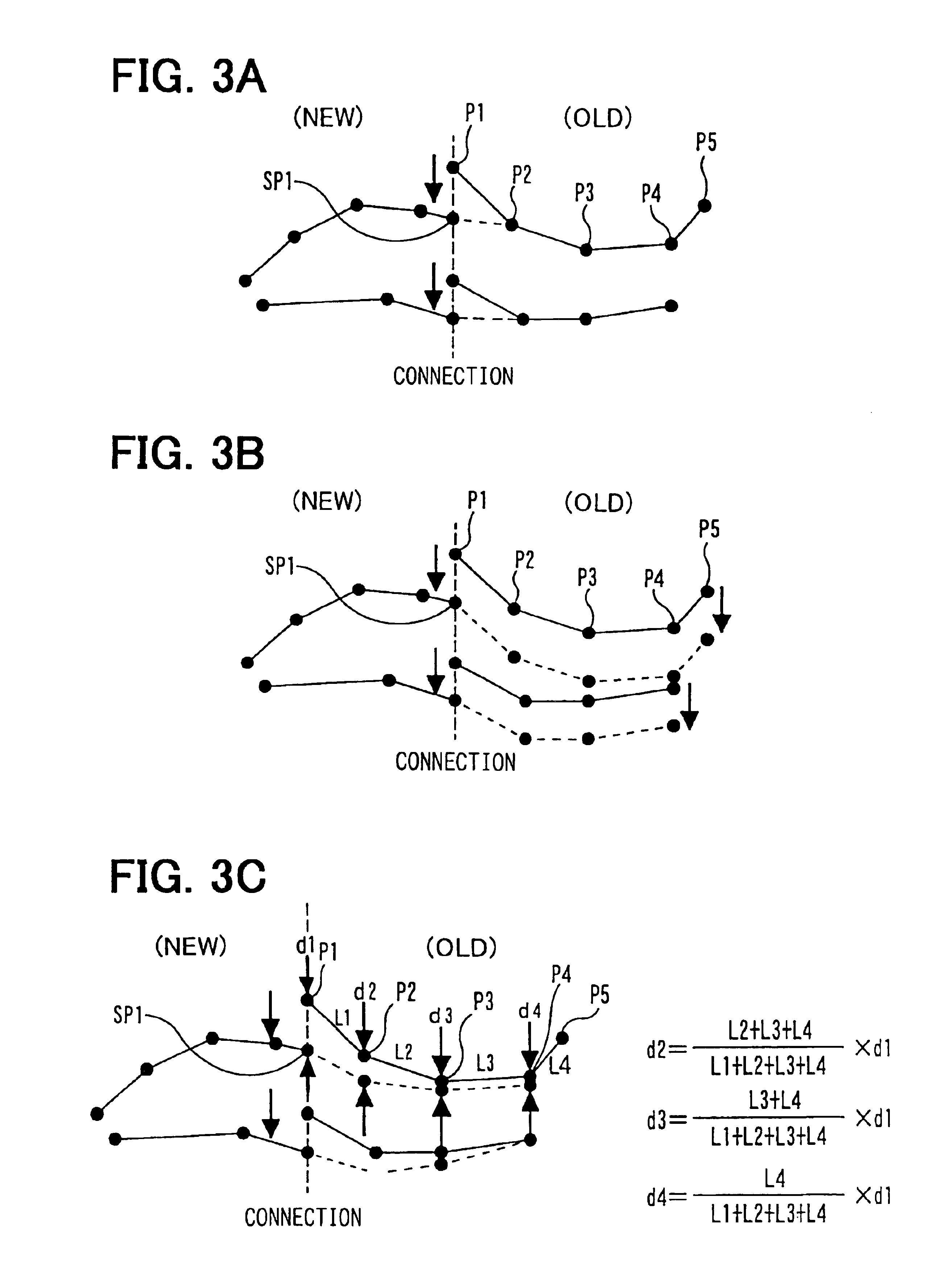

InactiveUS6922157B2Restrict degradation of appearanceConvenient and accurateInstruments for road network navigationRoad vehicles traffic controlSoftware engineeringMechanical engineering

Owner:DENSO CORP

Method for encapsulating pervious crystalline silicon solar cell modules

InactiveCN101533873ATo avoidGood effectFinal product manufactureSemiconductor devicesPolyesterCrystalline silicon

The invention discloses a method for encapsulating pervious crystalline silicon solar cell modules, comprising the following steps: upper and lower layers of macromolecular polyester films are arranged at the bottom and top of the solar cell modules featuring five layers of superposed structures, and the margins of the two layers of macromolecular polyester films exceed the margins of the solar cell modules featuring five layers of superposed structures; the preheating temperature of layer presses of the solar cell modules is set at 60-80 DEG C, the five layers of superposed structures are placed in the layer presses, the layer presses are vacuumized until the pressure is lower than 200kPa and the modules are pressurized; the lamination temperature of the layer presses is set at 135-145 DEG C, under which the lamination lasts for 15-25min, after lamination, the layer presses are opened for taking out the molded solar cell modules. The obtained solar cell modules are pervious and beautiful and eliminate bubbles, displacement, solar cell split and glass fragmentation faced by the pervious cell modules in the process of encapsulation.

Owner:SOUTH CHINA UNIV OF TECH

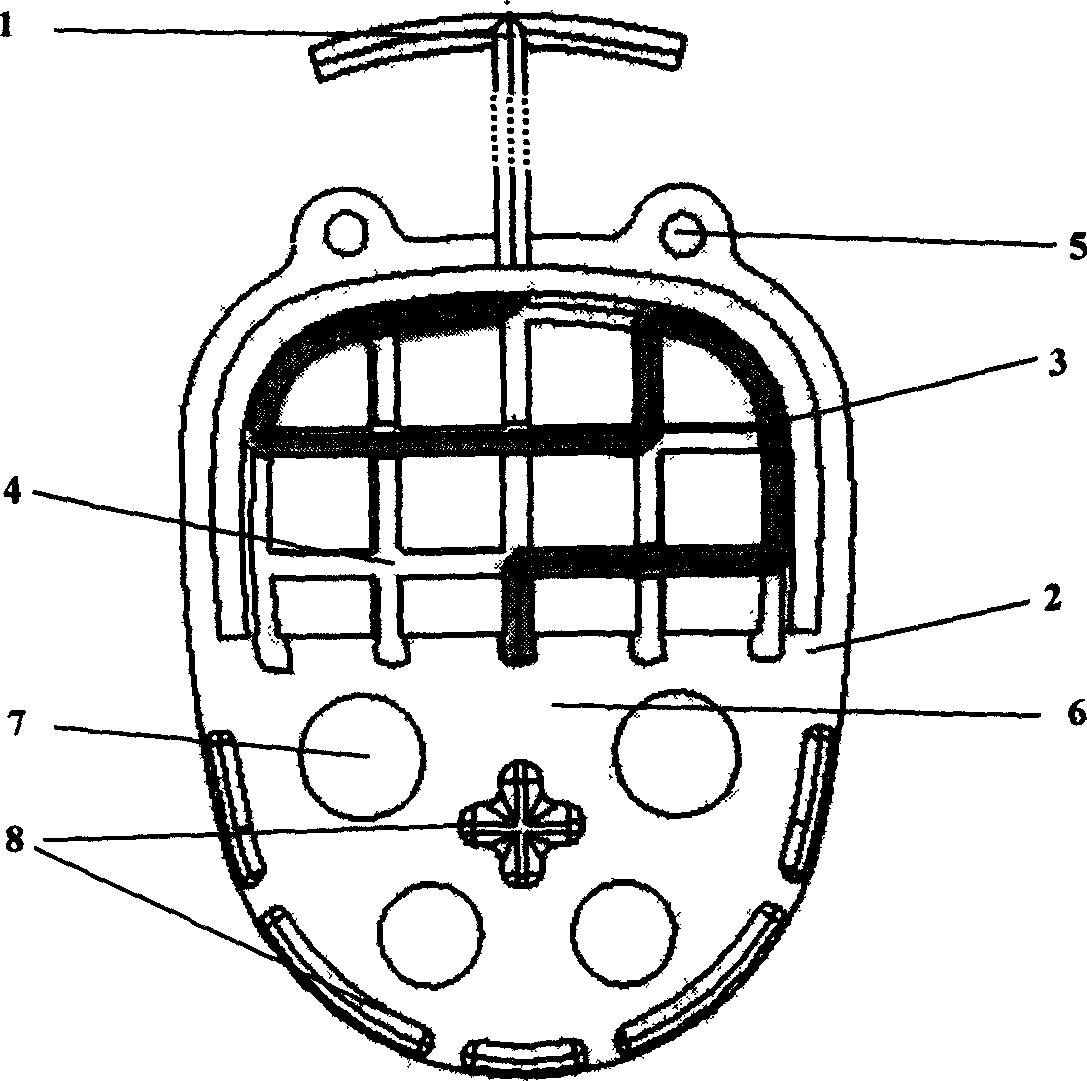

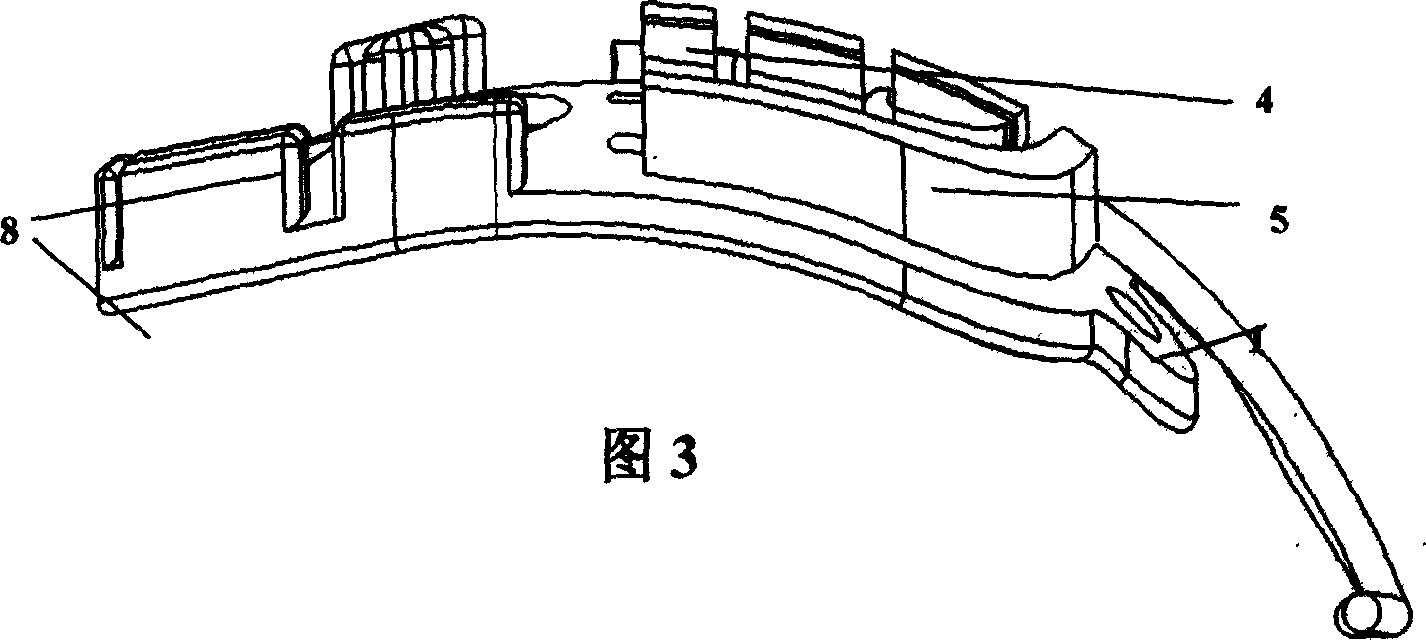

Novel aqueous humor drainage device for glaucoma

The novel aqueous humor drainage device for glaucoma consists of T-shaped pipe and draining disc connected together. The T-shaped pipe has an elastic transverse pipe with many homogeneously distributed humor inflowing holes in the aqueous humor contacting surface and a vertical pipe communicated perpendicularly with the transverse pipe and with back pressure controlling system. The draining disc has groove in the front part for the pressure controlling system, humor storing area in the back part, humor flow holes in the bottom and ridges in the center and the edge. The pressure controlling system is constituted in the extending part of the T-shaped pipe and inside the grooves of the draining disc. The aqueous humor drainage device makes the explant attached to the eyeball closely, has expanded filtering volume to reduce the stimulation to eyeball and peripheral tissue. It has good implanting operation performance, and can lower eye pressure and control eye pressure in normal range.

Owner:XI AN JIAOTONG UNIV

Foldable three-dimensional double-opening iron core oil-immersed transformer

InactiveCN105513756AHigh mechanical strengthEasy to loosenTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerLow voltage

The invention discloses a foldable three-dimensional double-opening iron core oil-immersed transformer. The foldable three-dimensional double-opening iron core oil-immersed transformer comprises a double-opening transformer iron core having an L-shaped interlock structure, wherein the iron core is formed by splicing three single-frame double-opening iron cores at an center angle of 120 degrees, and the cross section of the spliced iron core is in an inscribed polygonal shape of a circle, an circular shape (R type) and a regular hexagonal shape; the iron core is arranged in an oil tank, three side surfaces of the oil tank are each provided with a heat radiation device, and the outer side of a core column is sequentially sleeved by a low-voltage coil and a high-voltage coil from inside to outside. The iron core of the foldable three-dimensional double-opening iron core oil-immersed transformer adopts a ferrite yoke and core column interlock structure, so that the foldable three-dimensional double-opening iron core oil-immersed transformer has the characteristics of low loss, small noise, high sudden short circuit resistance, high iron core mechanical strength and high production efficiency.

Owner:齐侠

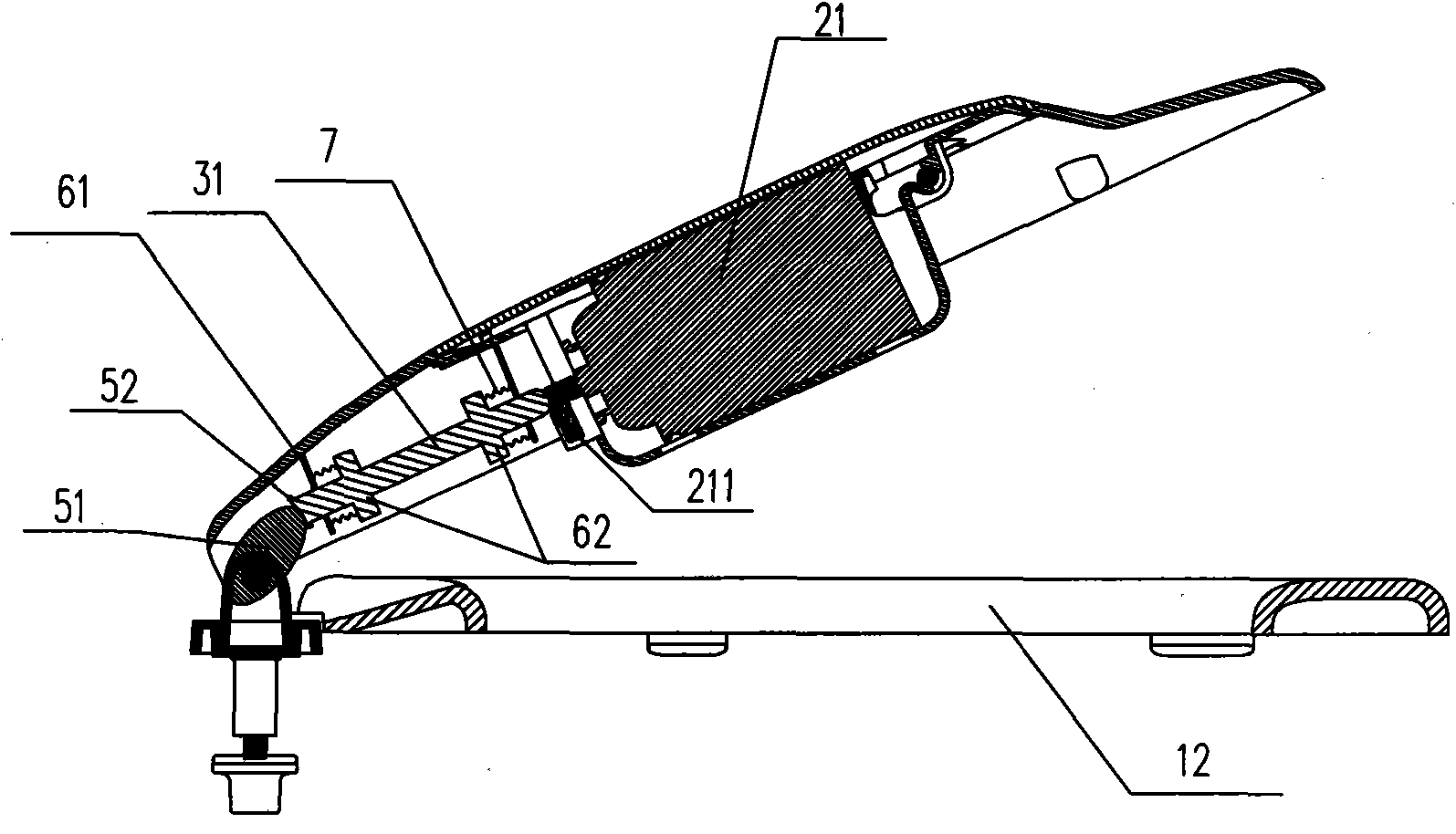

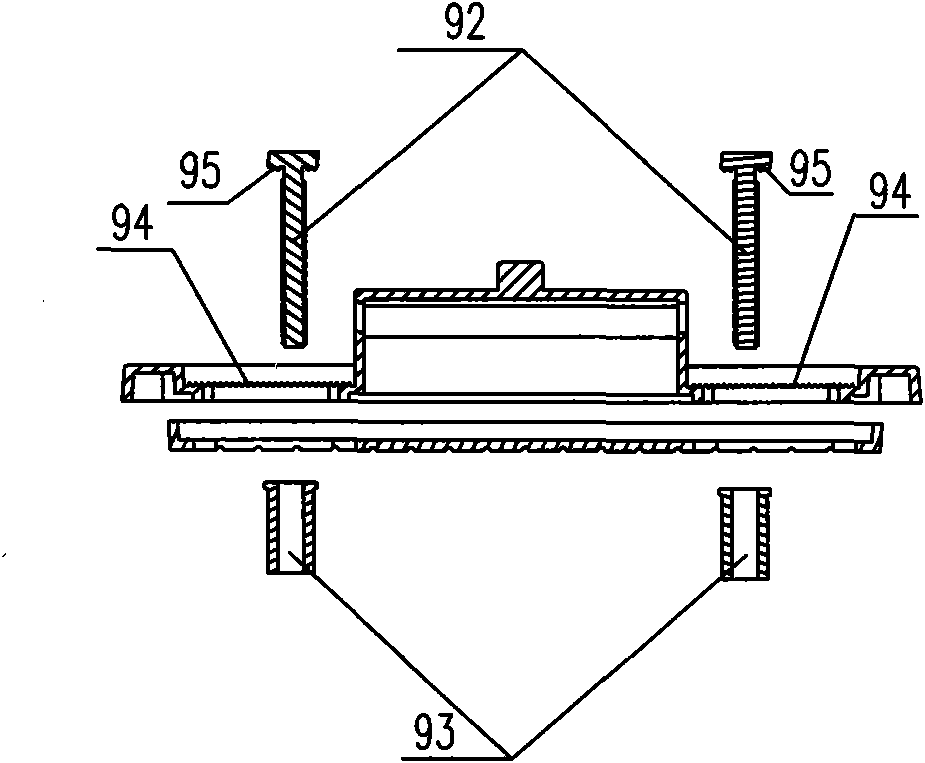

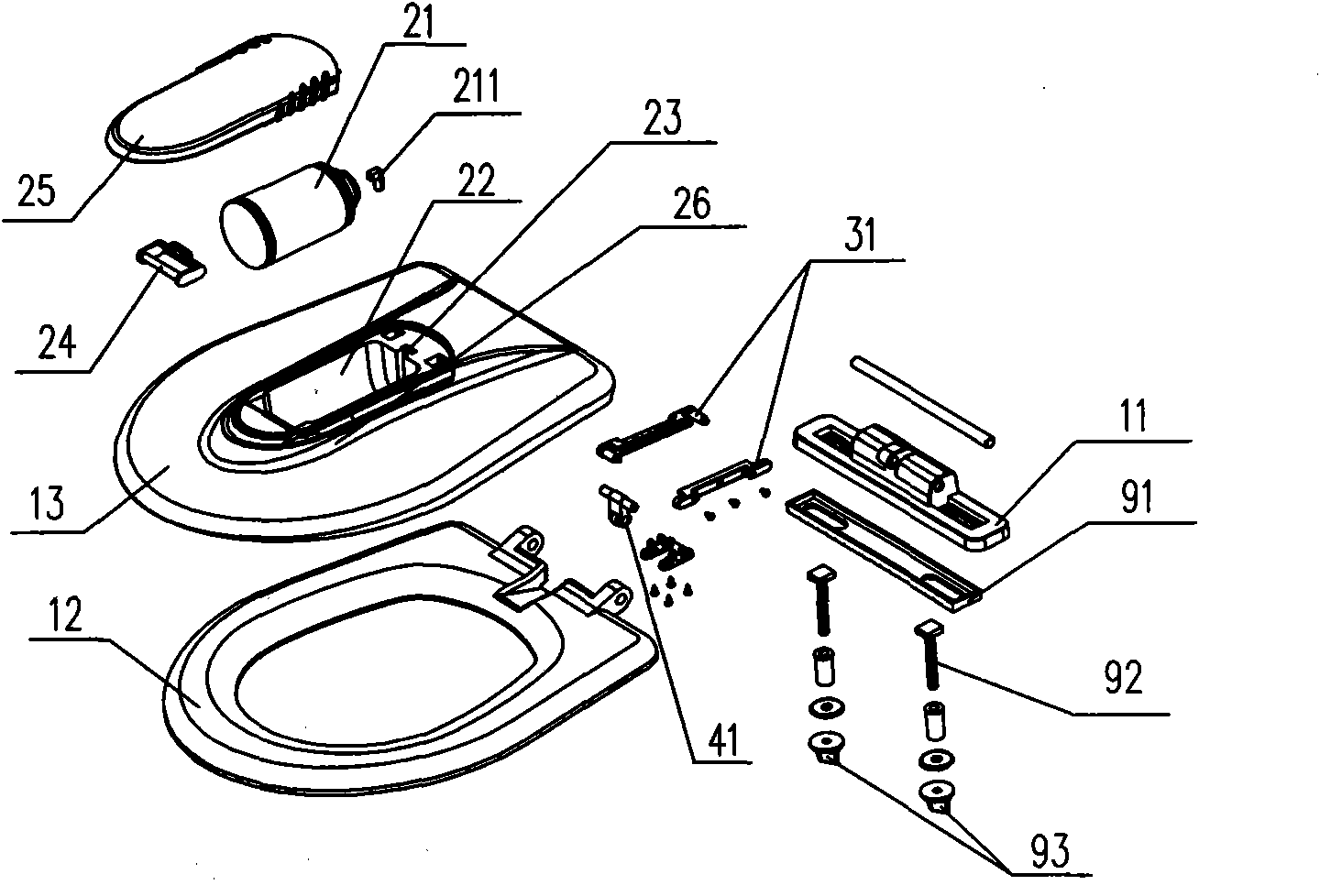

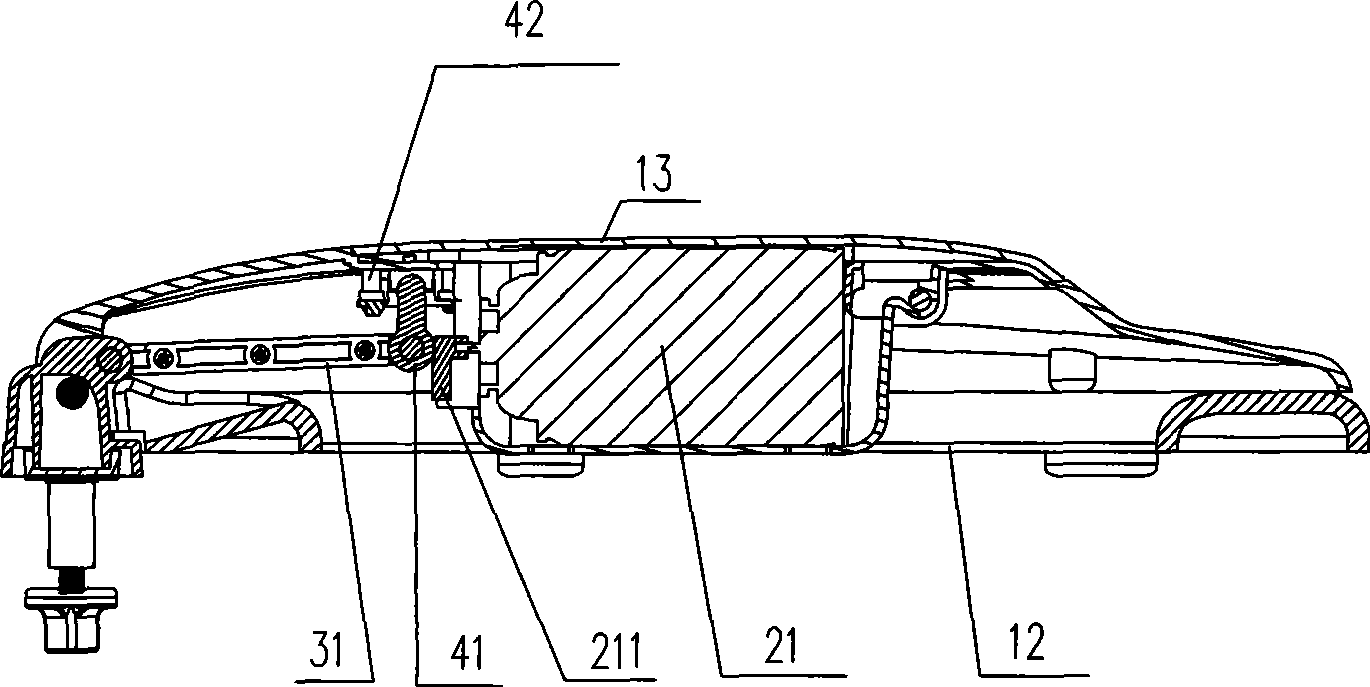

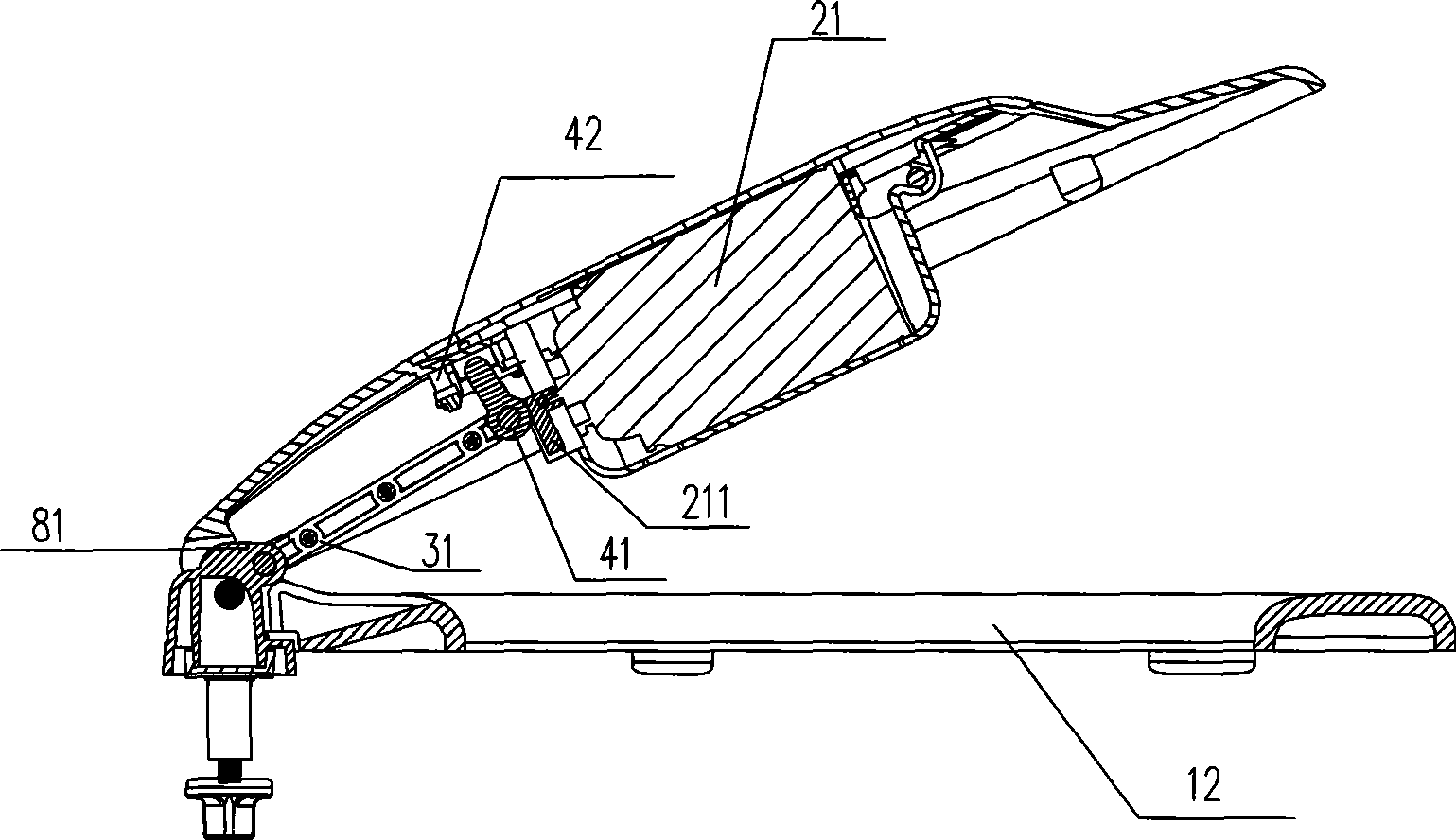

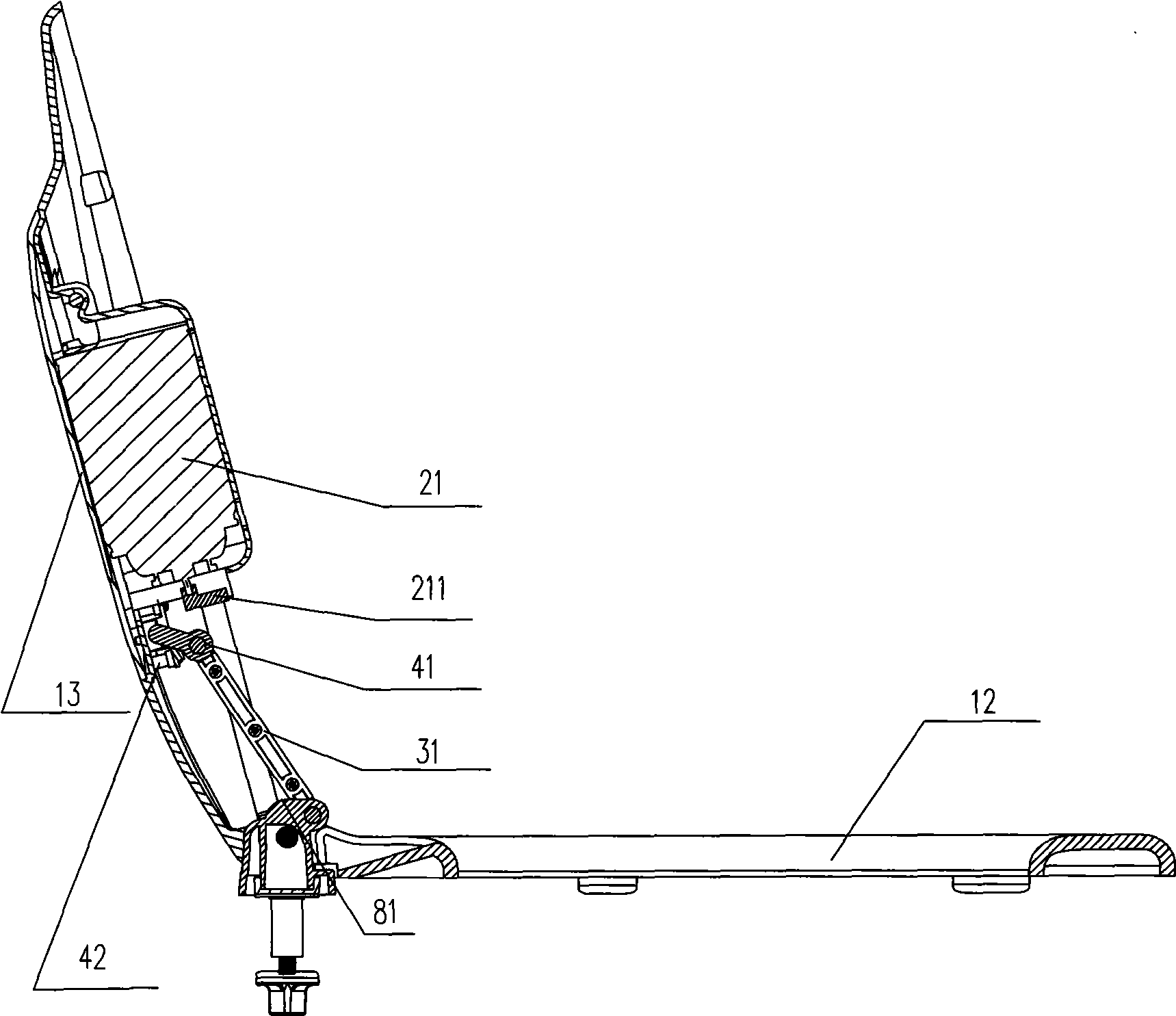

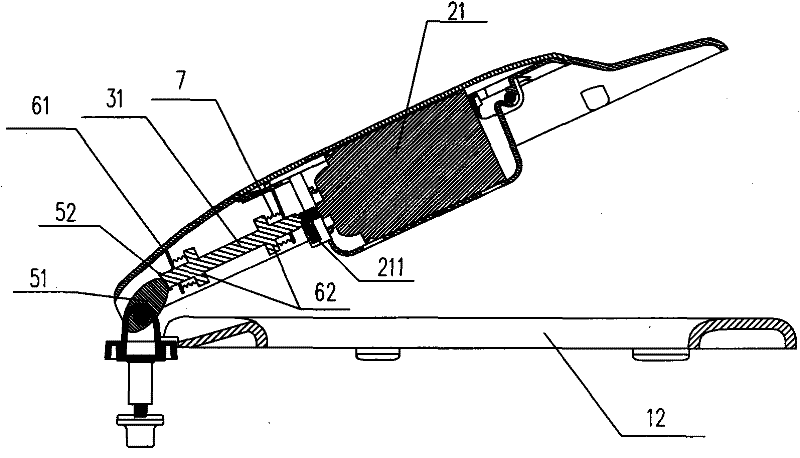

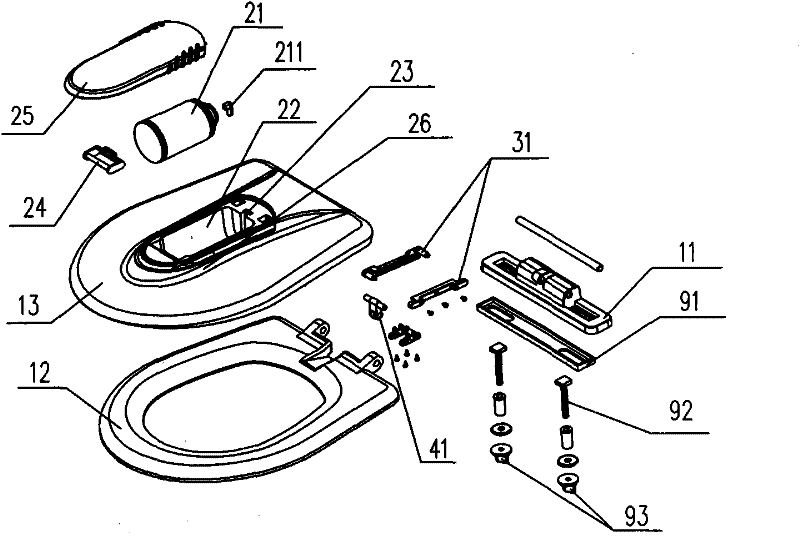

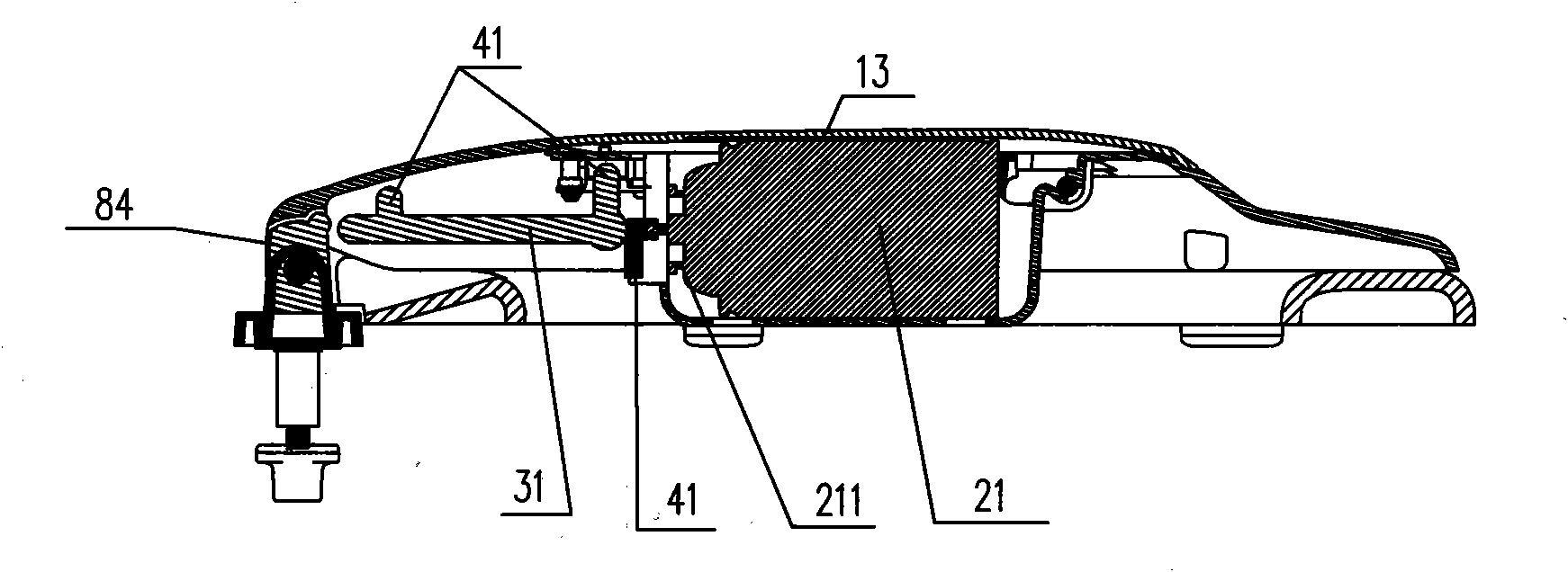

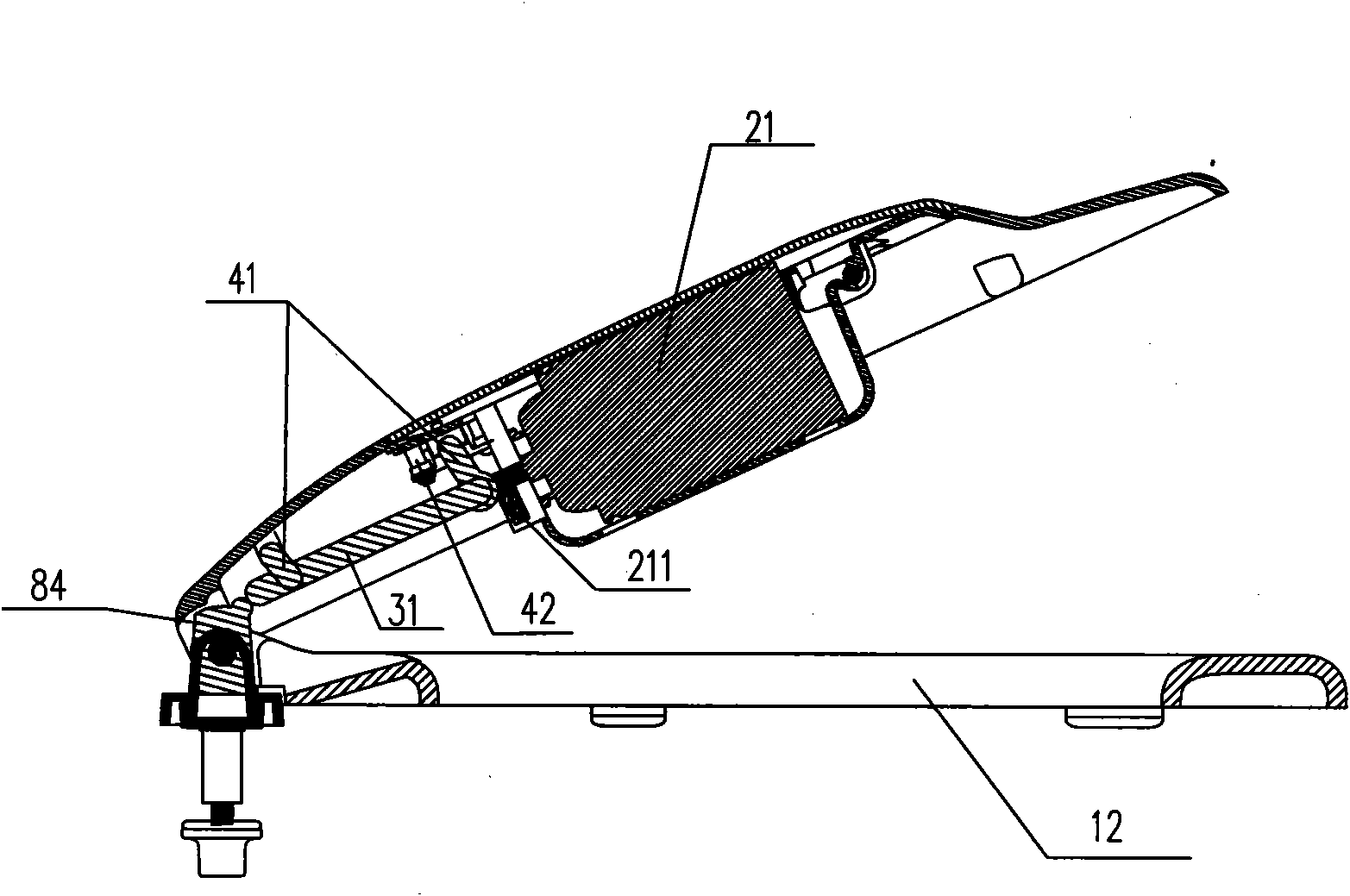

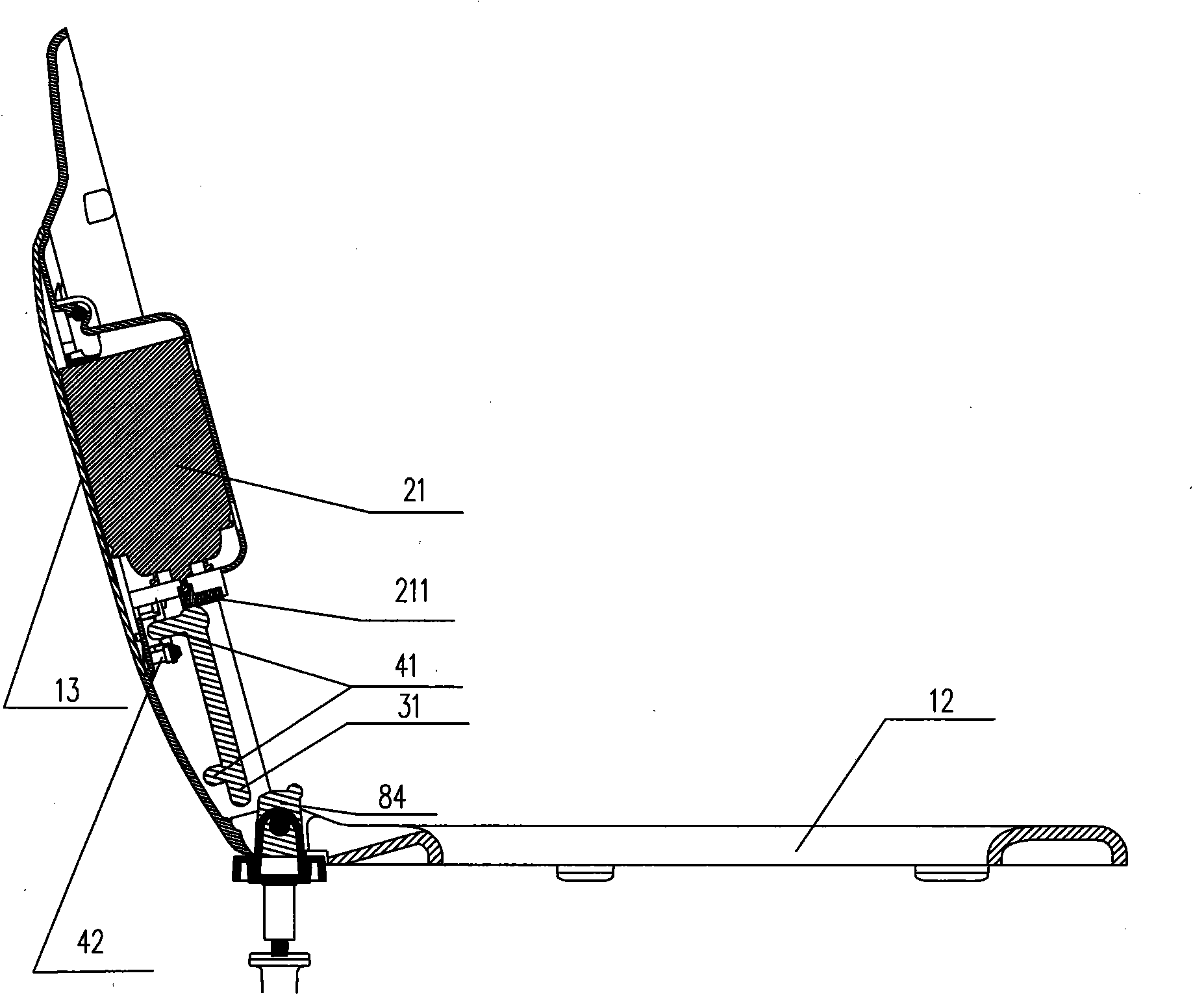

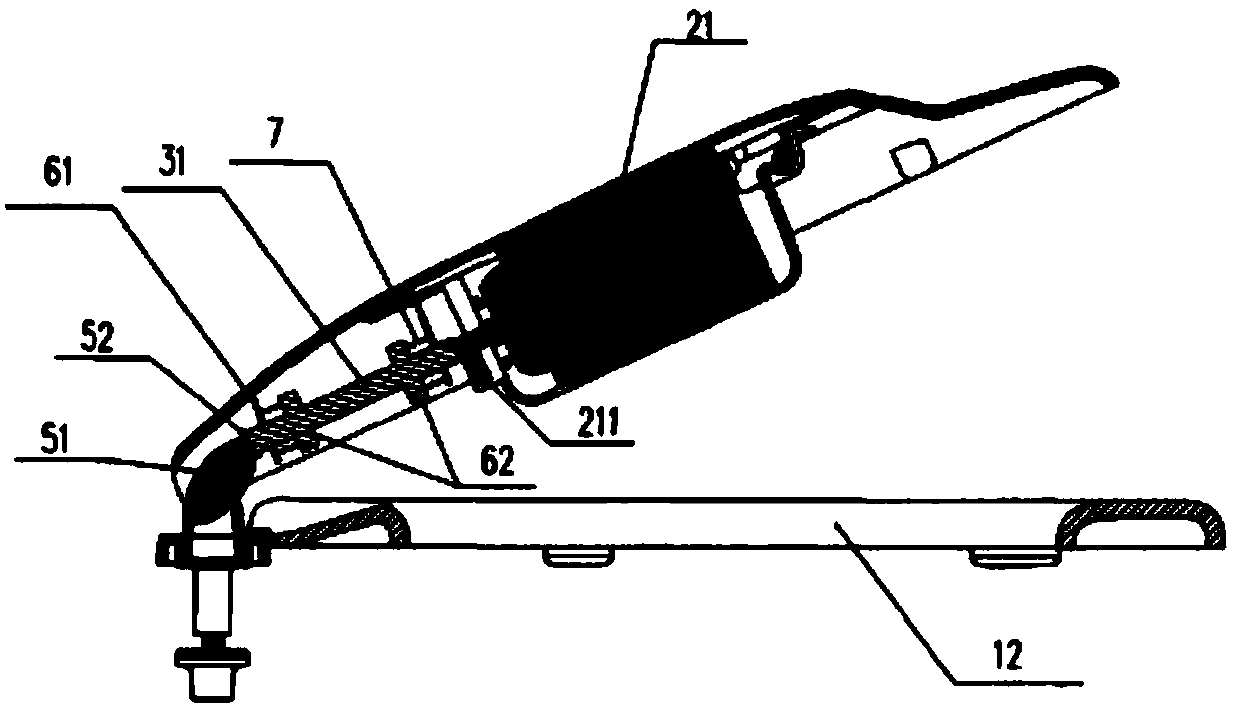

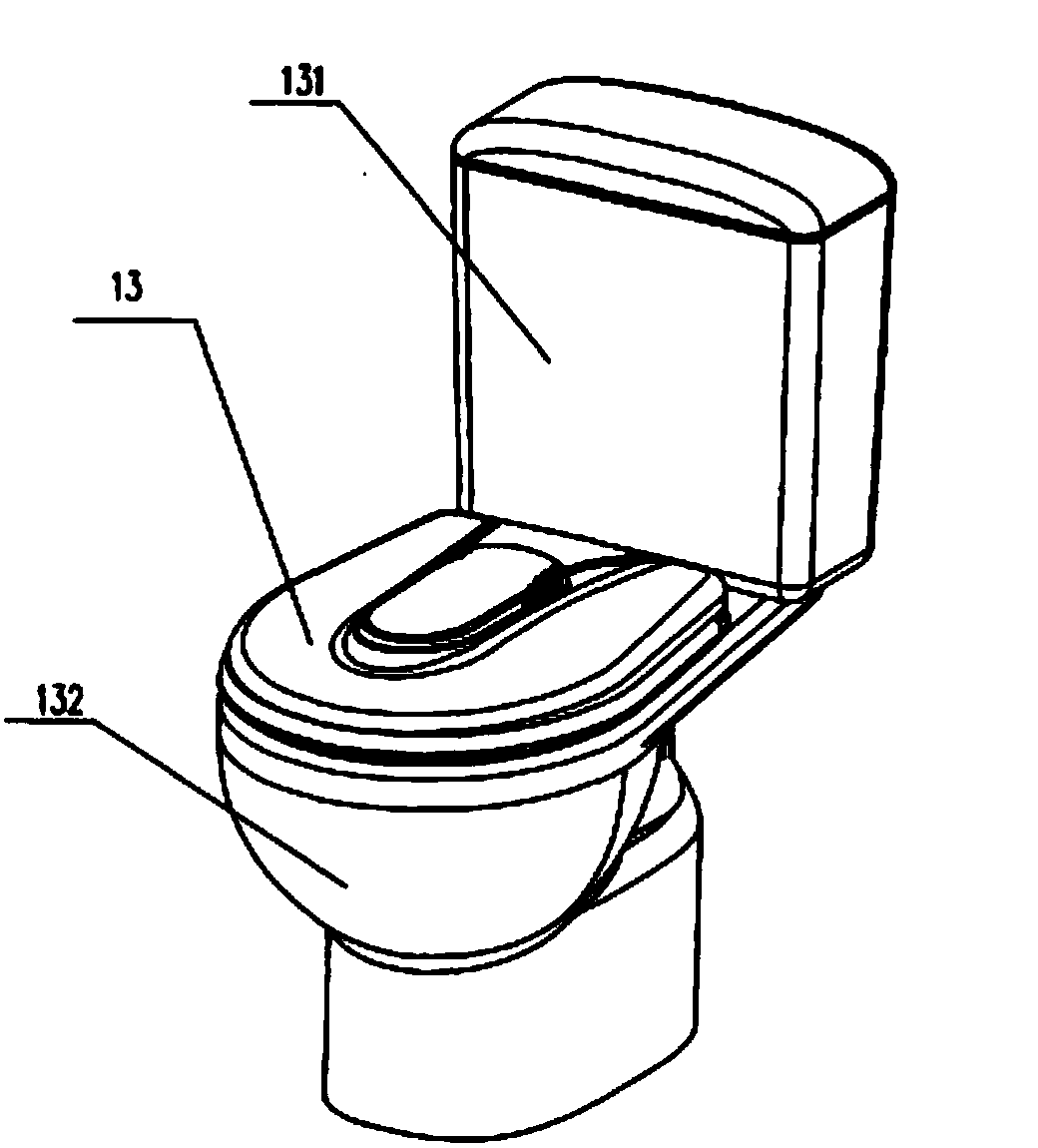

Toilet having built-in spraying system plate cover

InactiveCN101933781ASolve the weight problemSolve the shiftFlushing devicesBathroom coversToiletNozzle

The invention discloses a toilet having a built-in spraying system plate cover. A toilet plate cover assembly is arranged on a toilet body and comprises a fixed base fixed on the toilet body, a seat retainer coaxially arranged on the fixed base and a toilet plate cover, wherein the toilet plate cover is provided with a spray tank fixing structure for positioning and holding a common sterilizing scented spray tank; a trigger mechanism which is opened and closed by the toilet plate cover to trigger a nozzle to act is arranged at a position opposite to the nozzle of the spray tank; and the outlet of the nozzle points to the inner bottom of the seat retainer in a horizontal state when the nozzle is triggered. The toilet is designed for culturing household and personal health consciousness, can force a user to sterilize and spray the toilet before and after the use of the toilet so as to ensure that all people can enjoy a scented and sanitary washroom at any time, and has the advantages of simple and novel structure, simple and convenient manufacturing, low cost and easy popularization.

Owner:开平雅琪塑胶机械模具厂

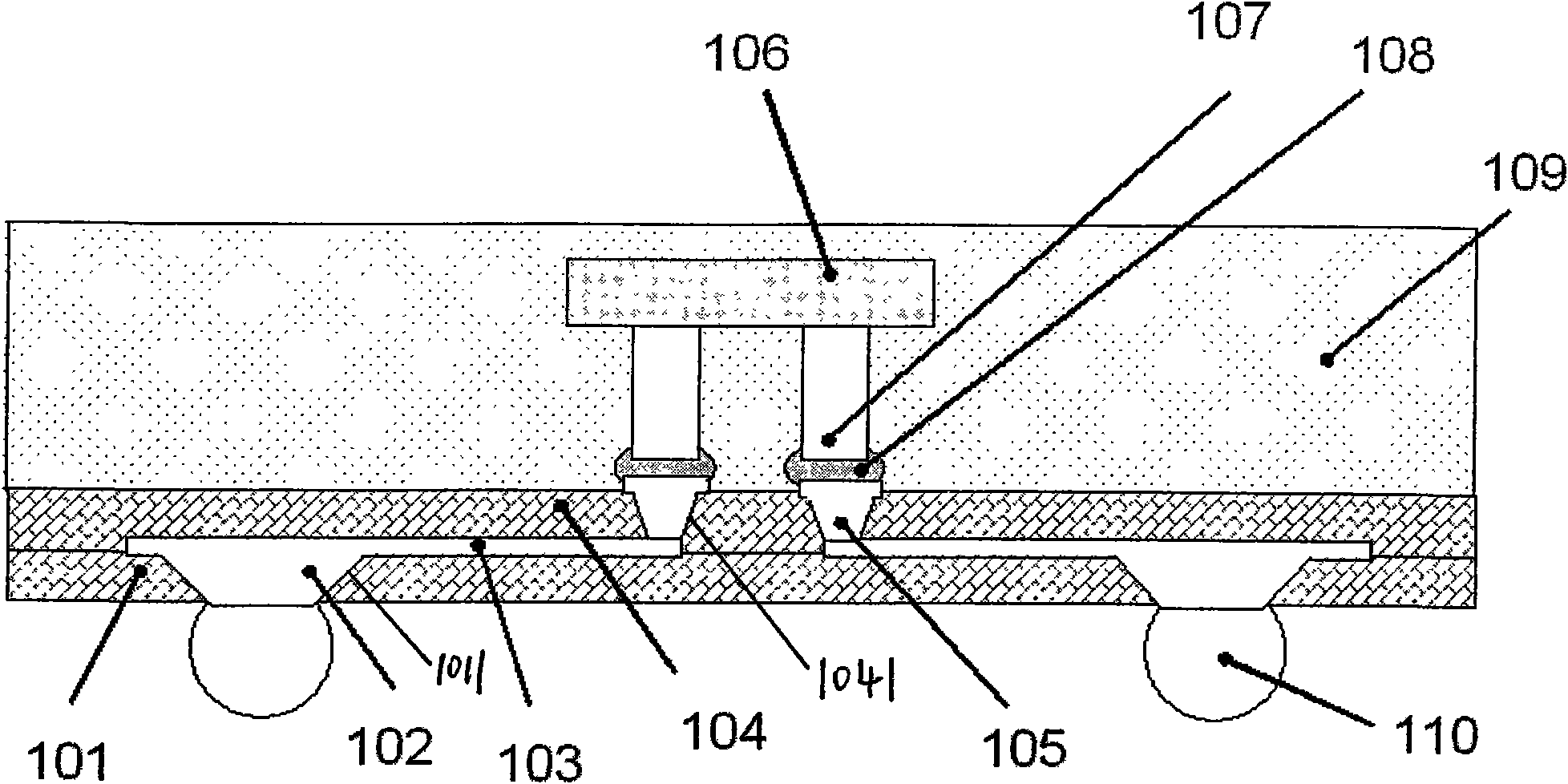

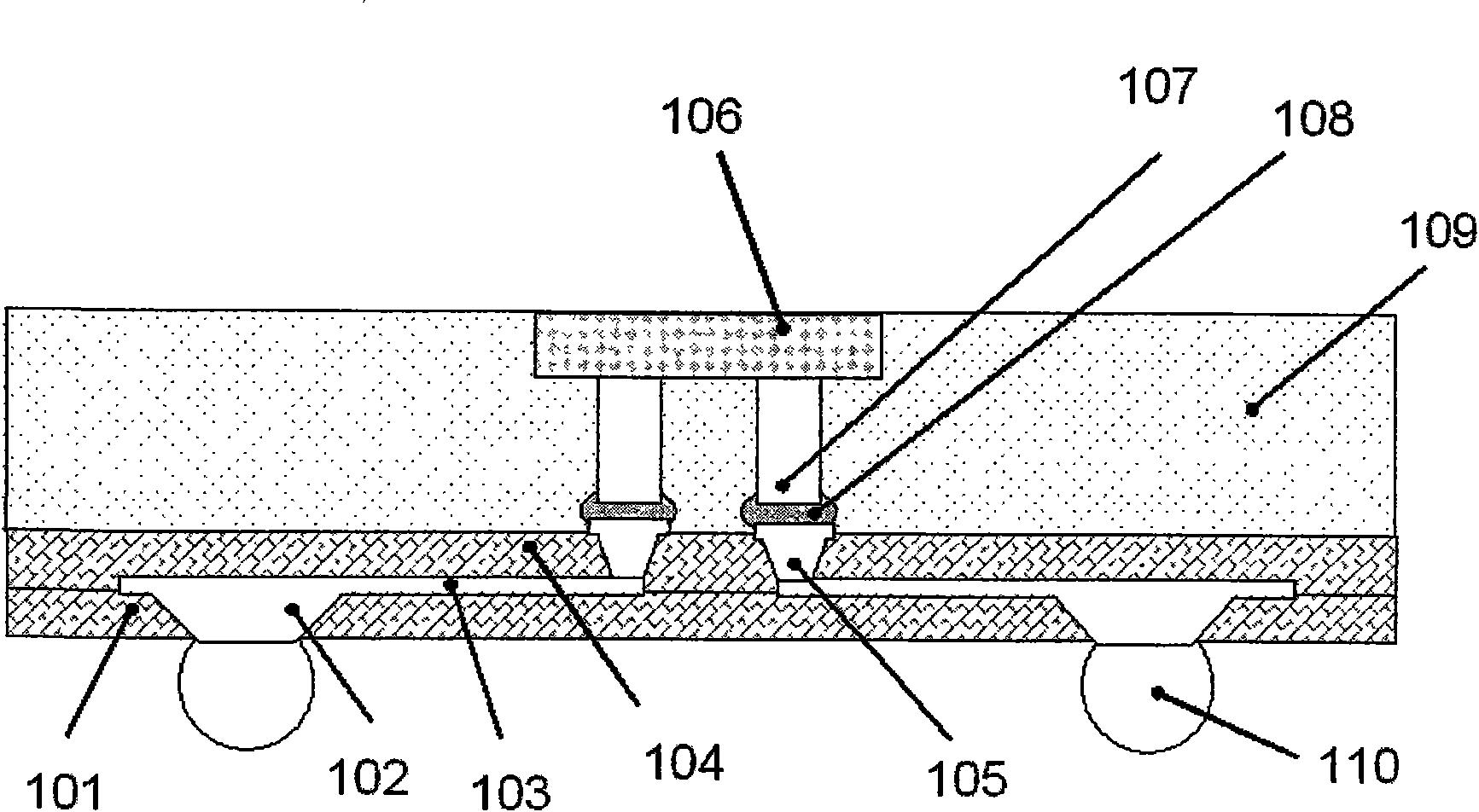

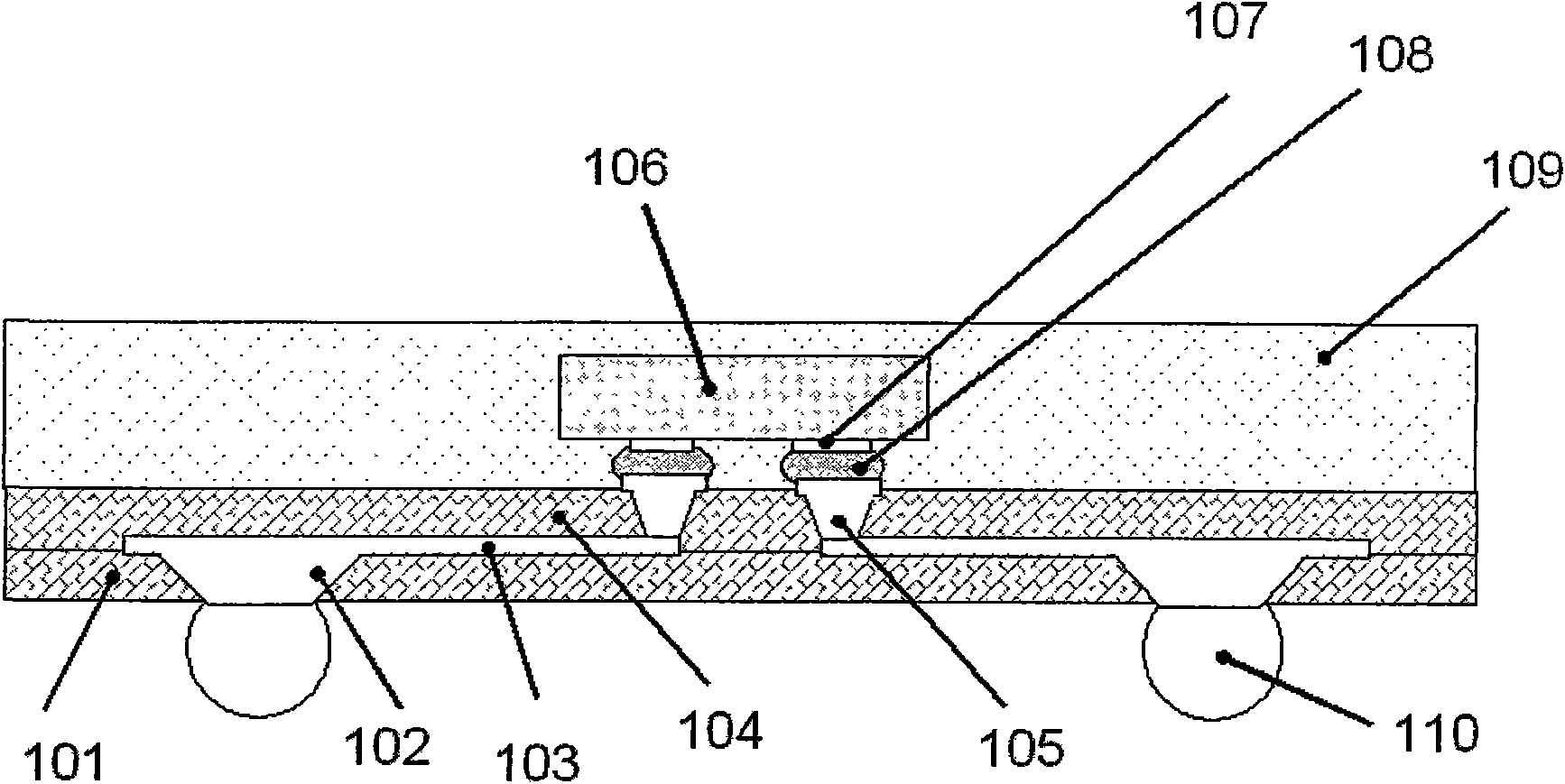

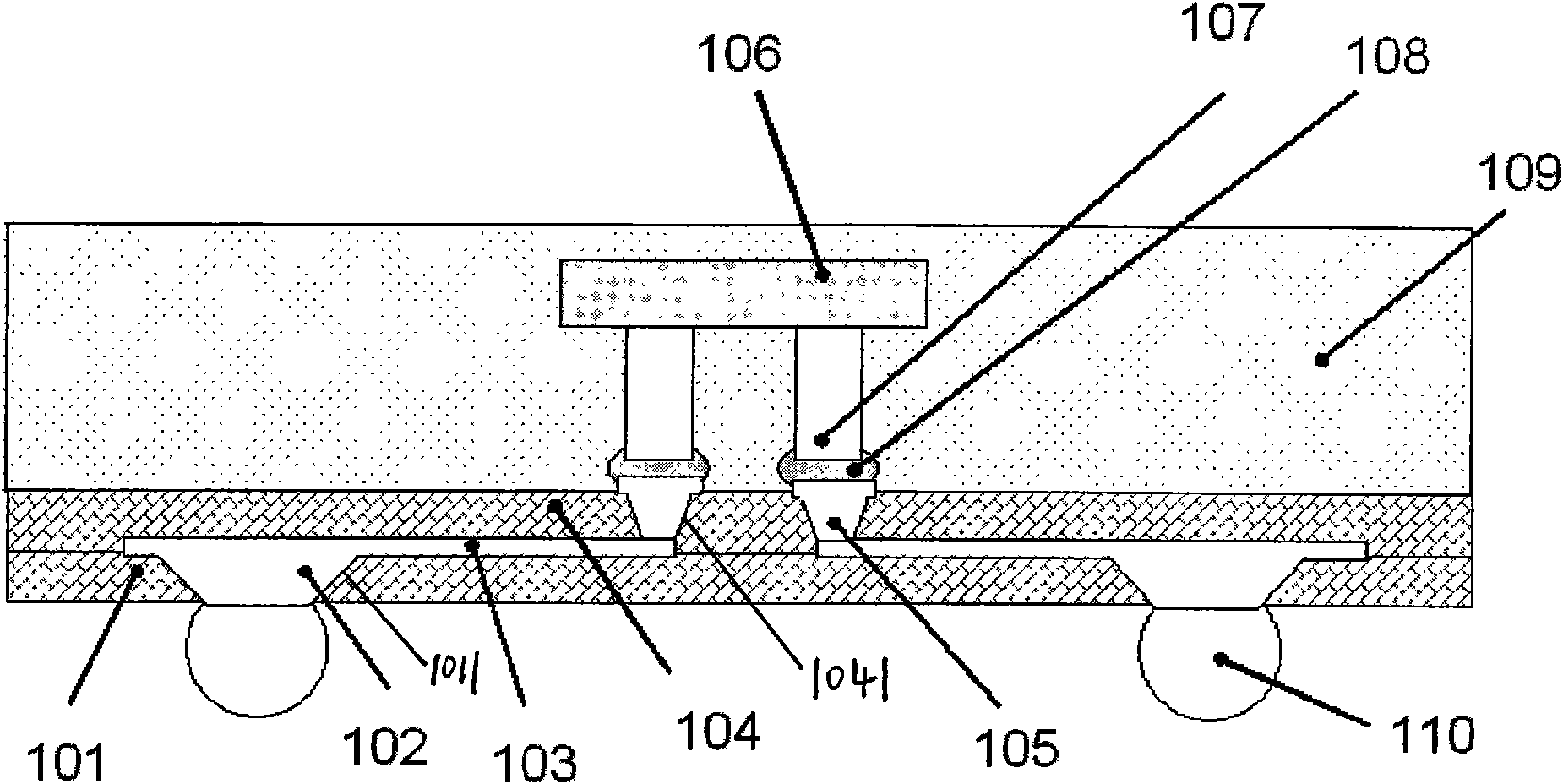

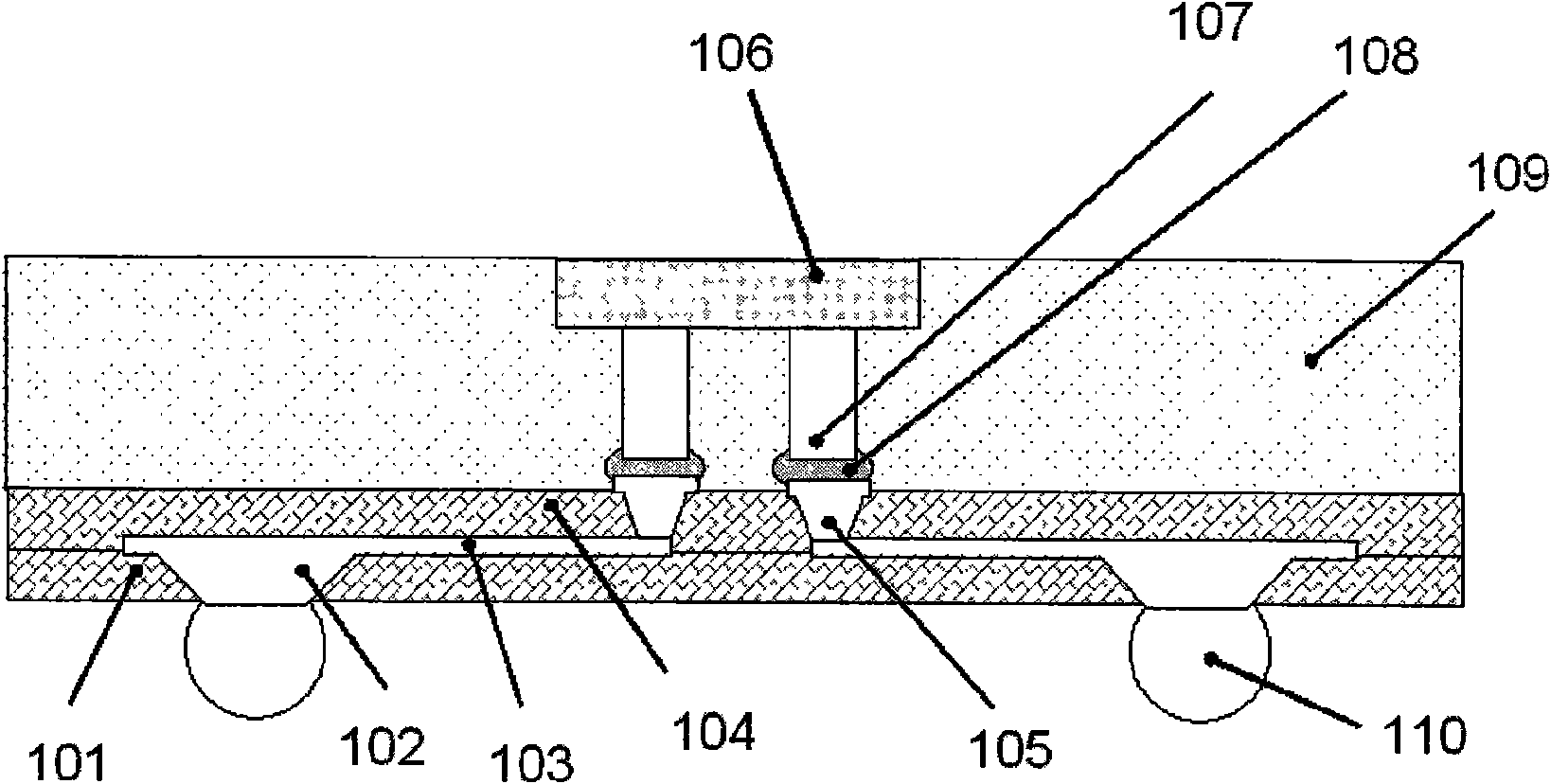

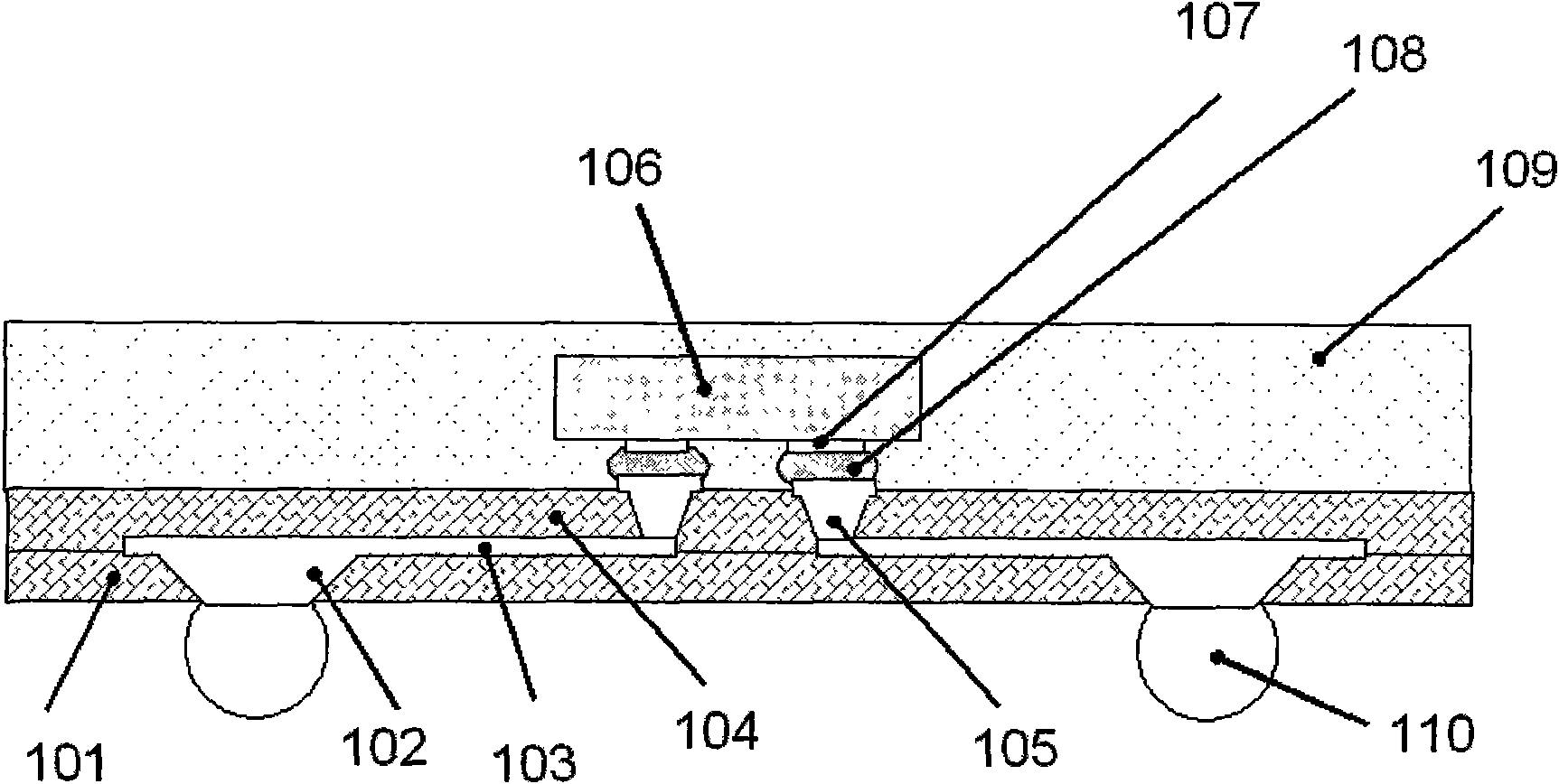

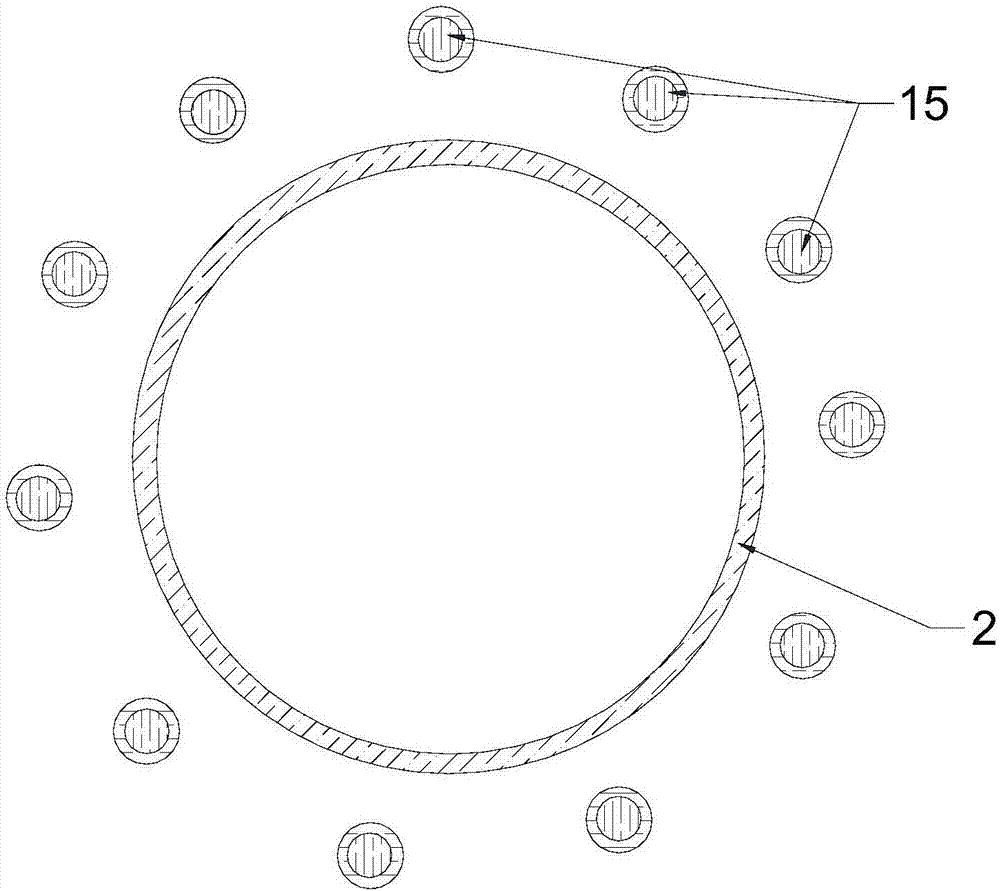

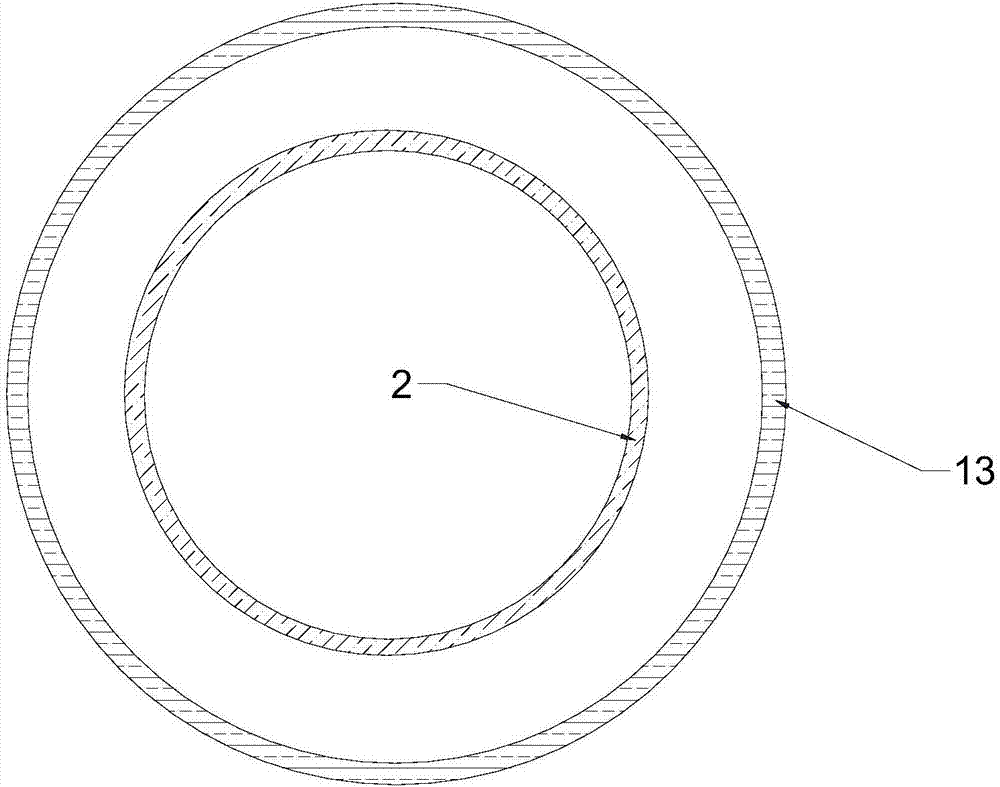

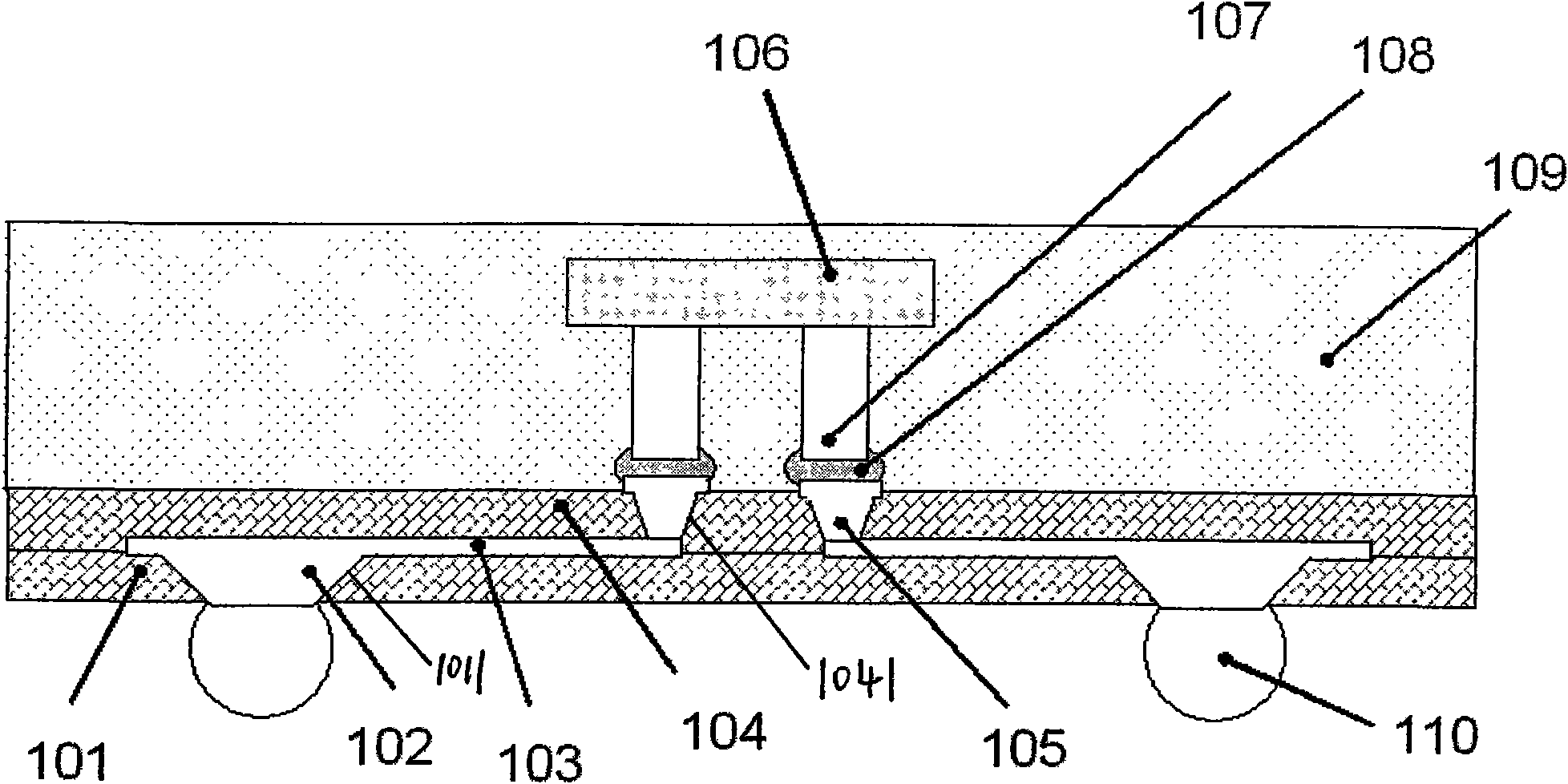

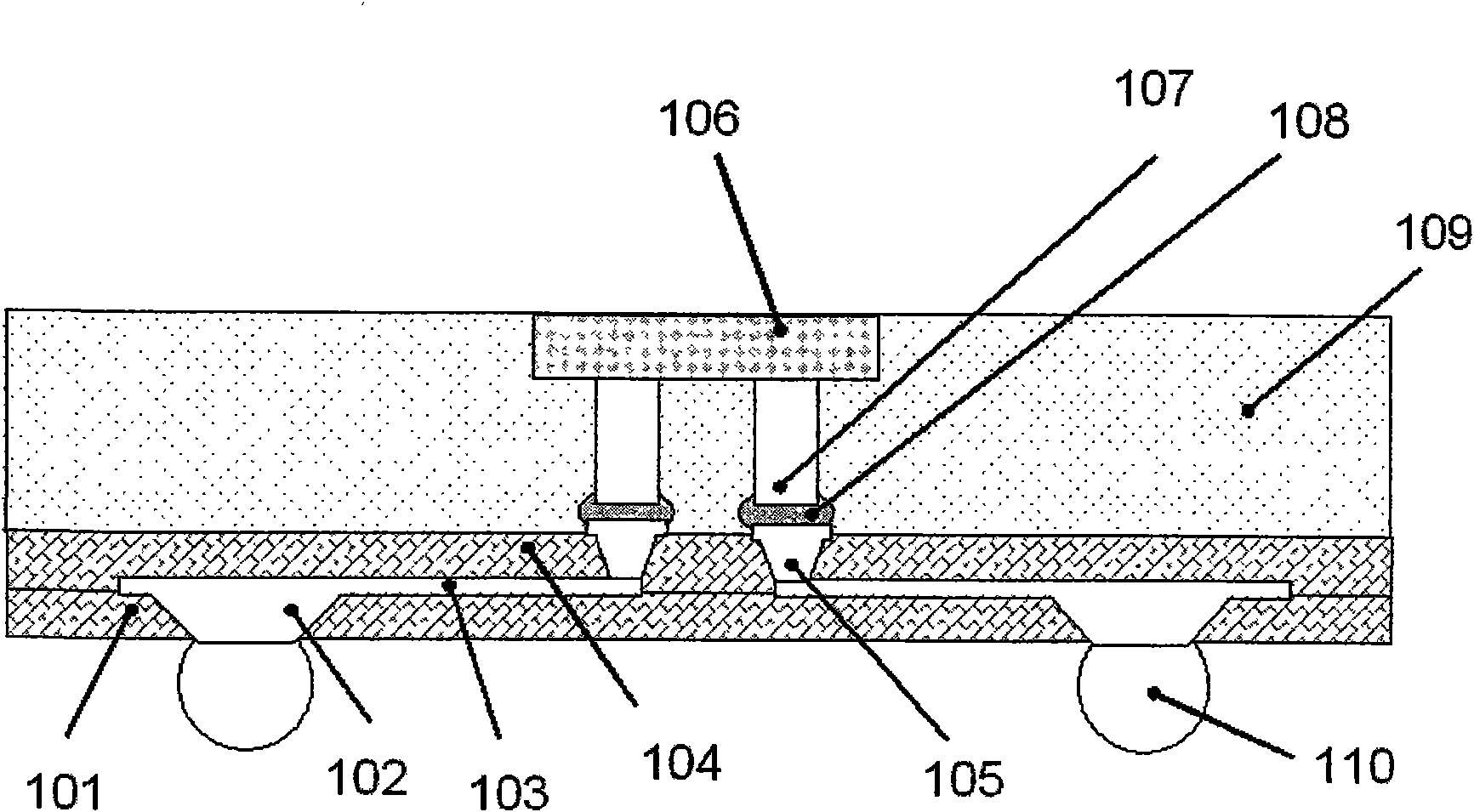

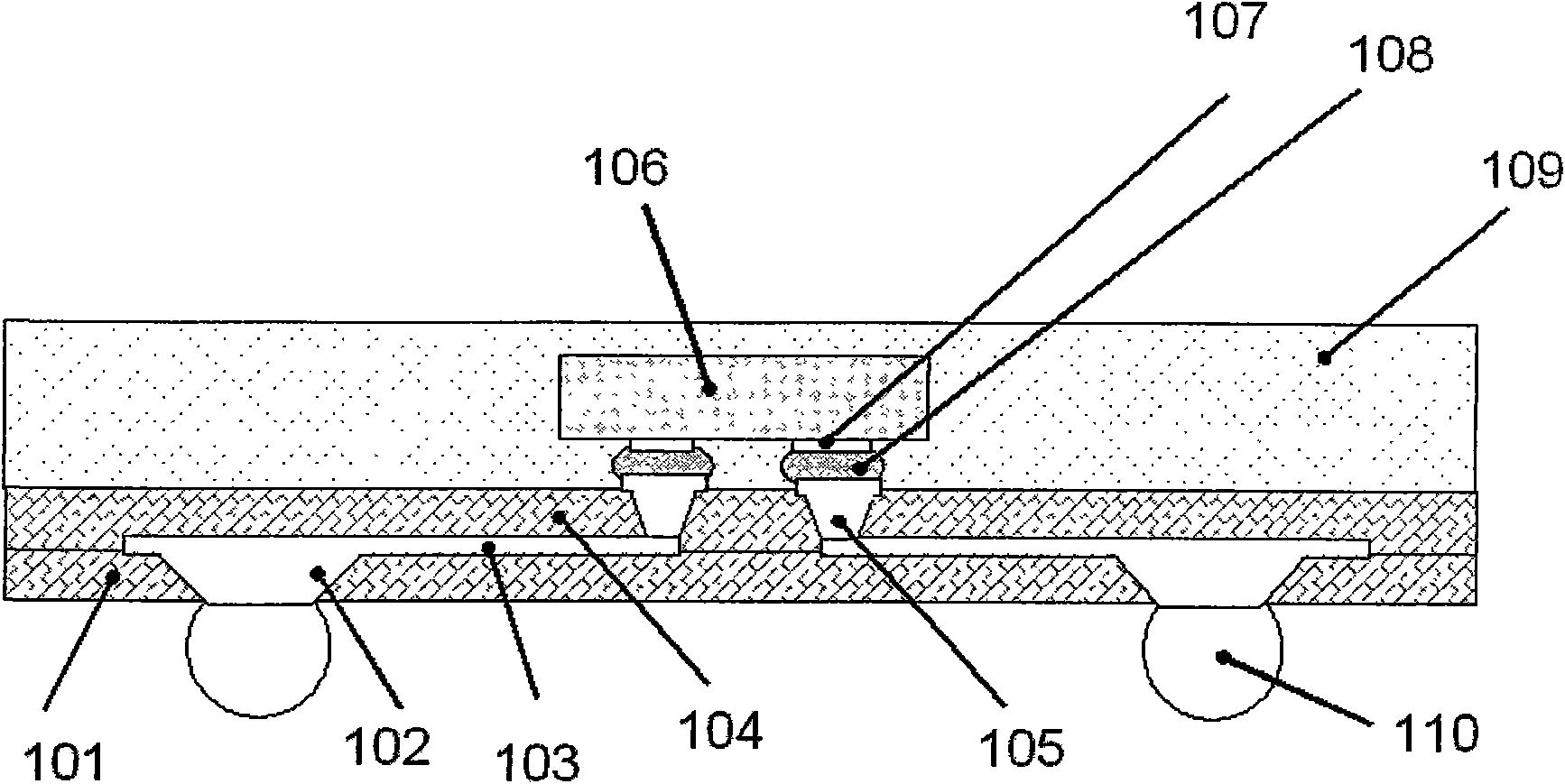

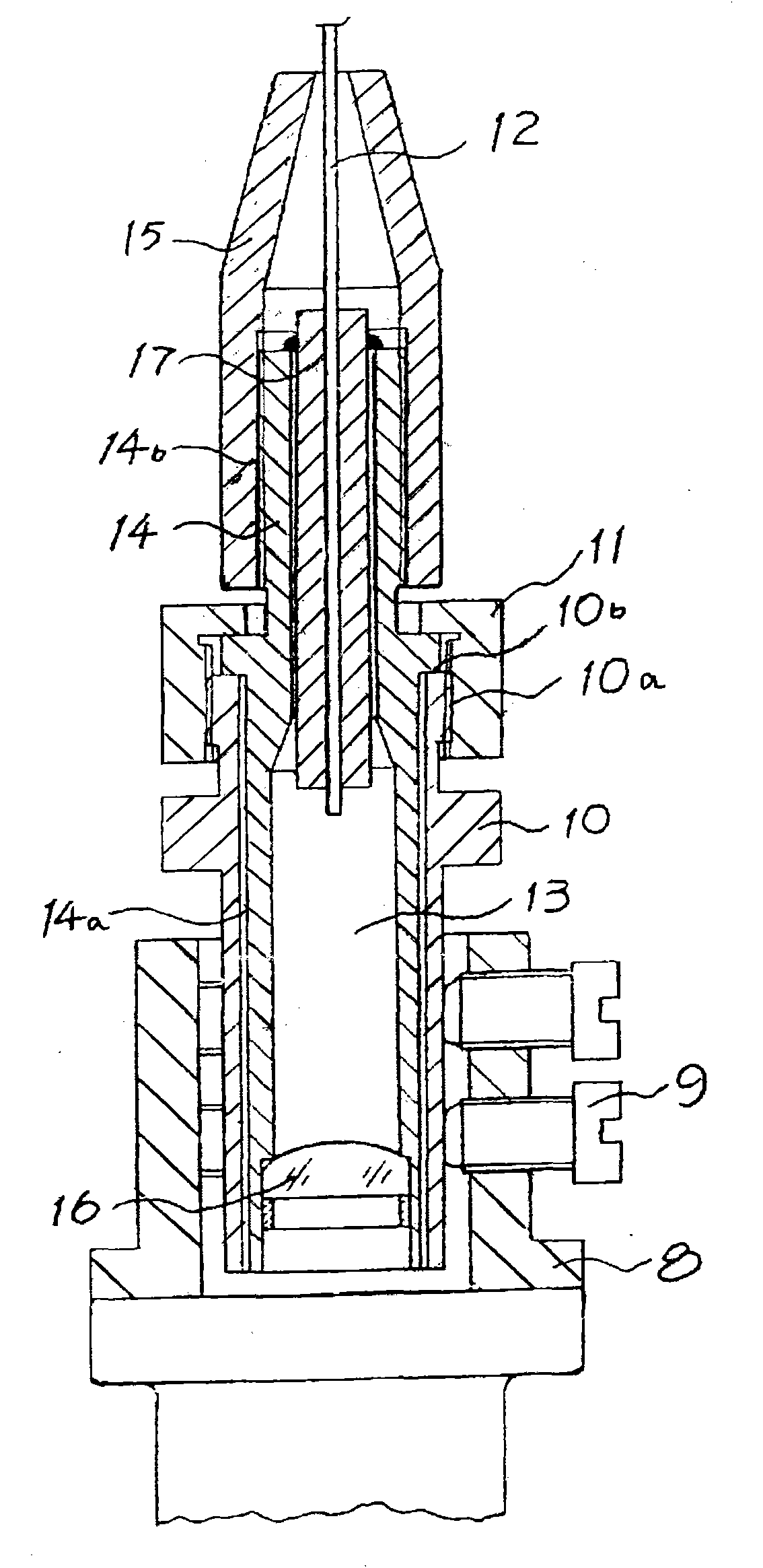

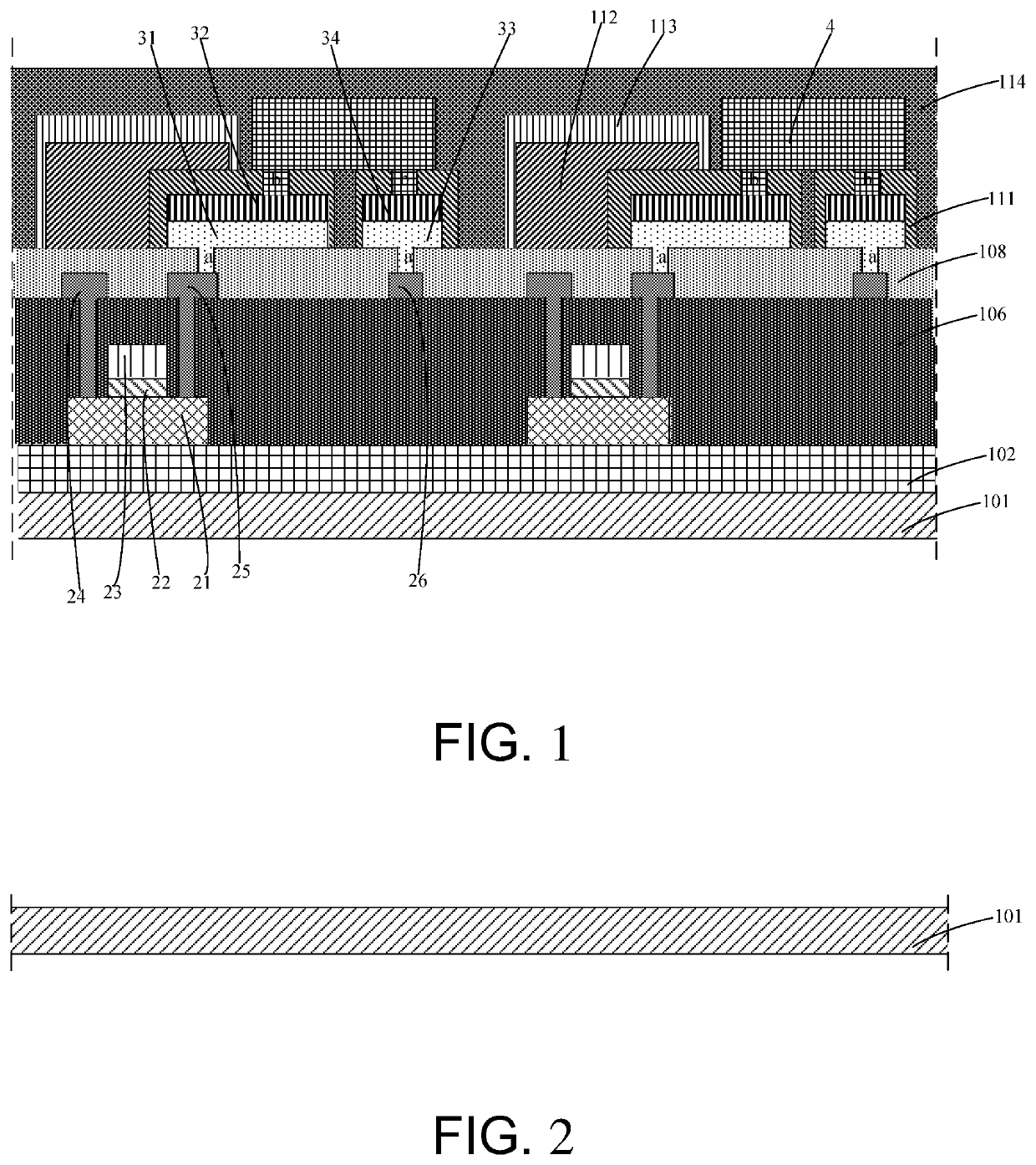

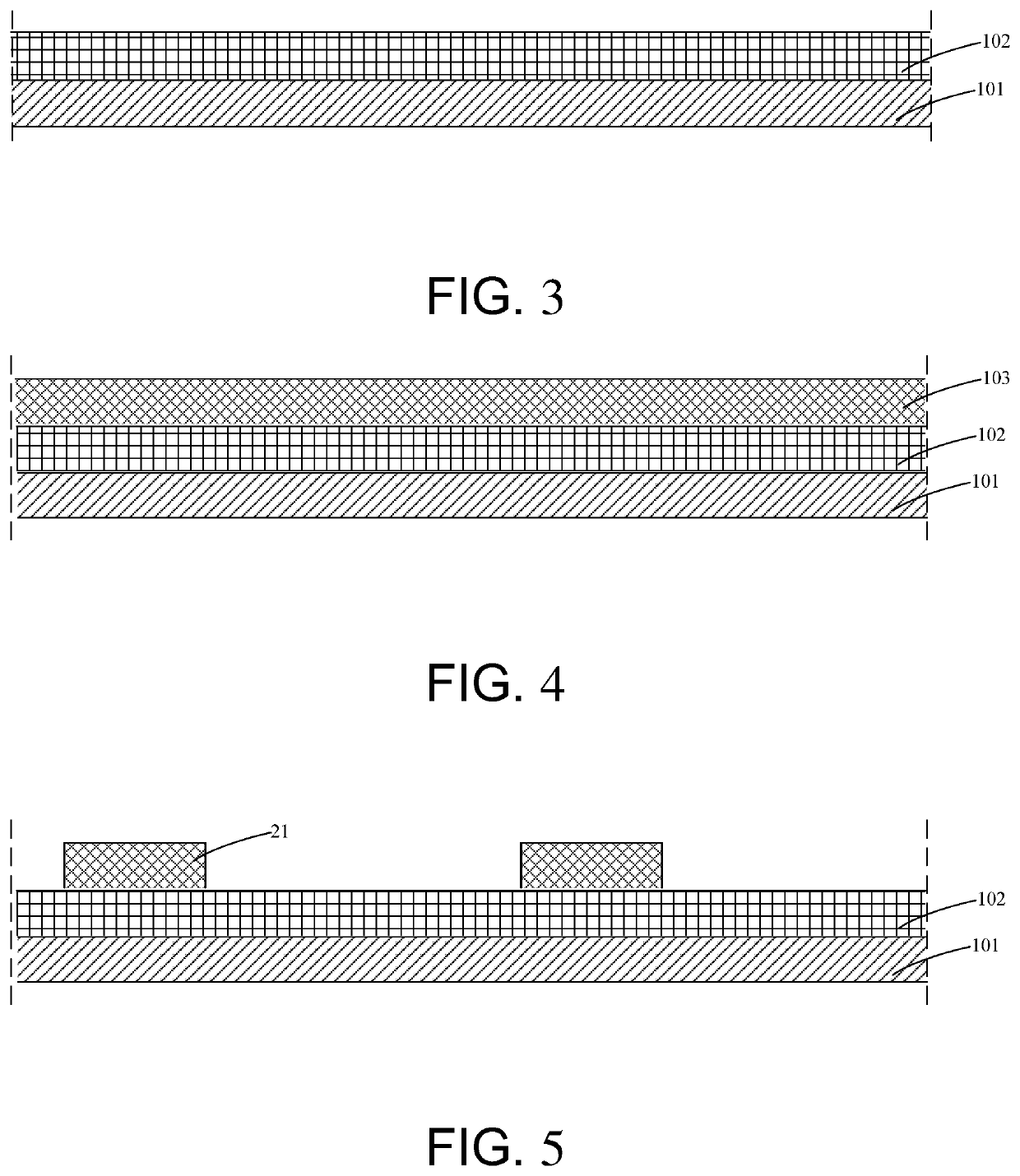

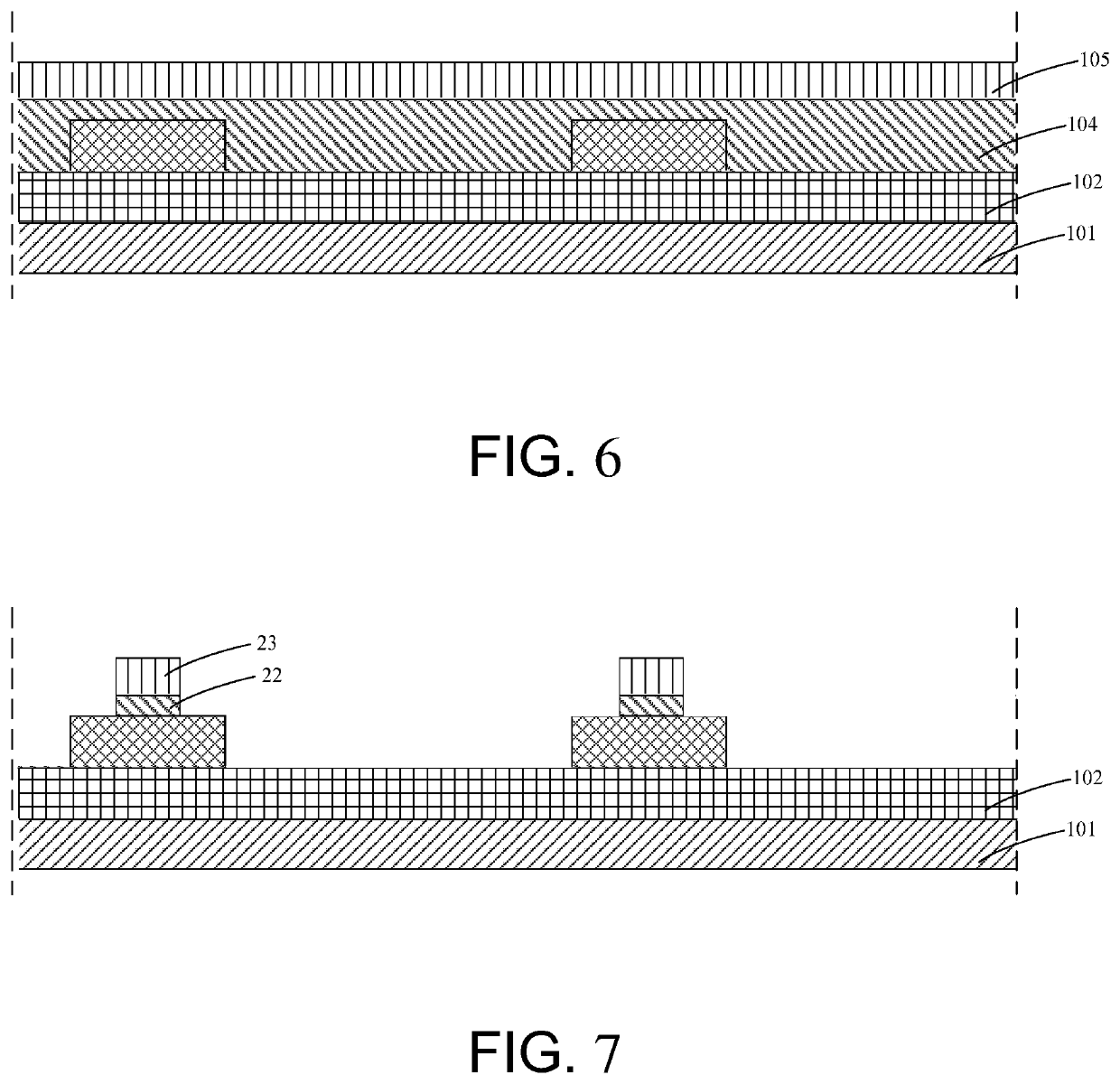

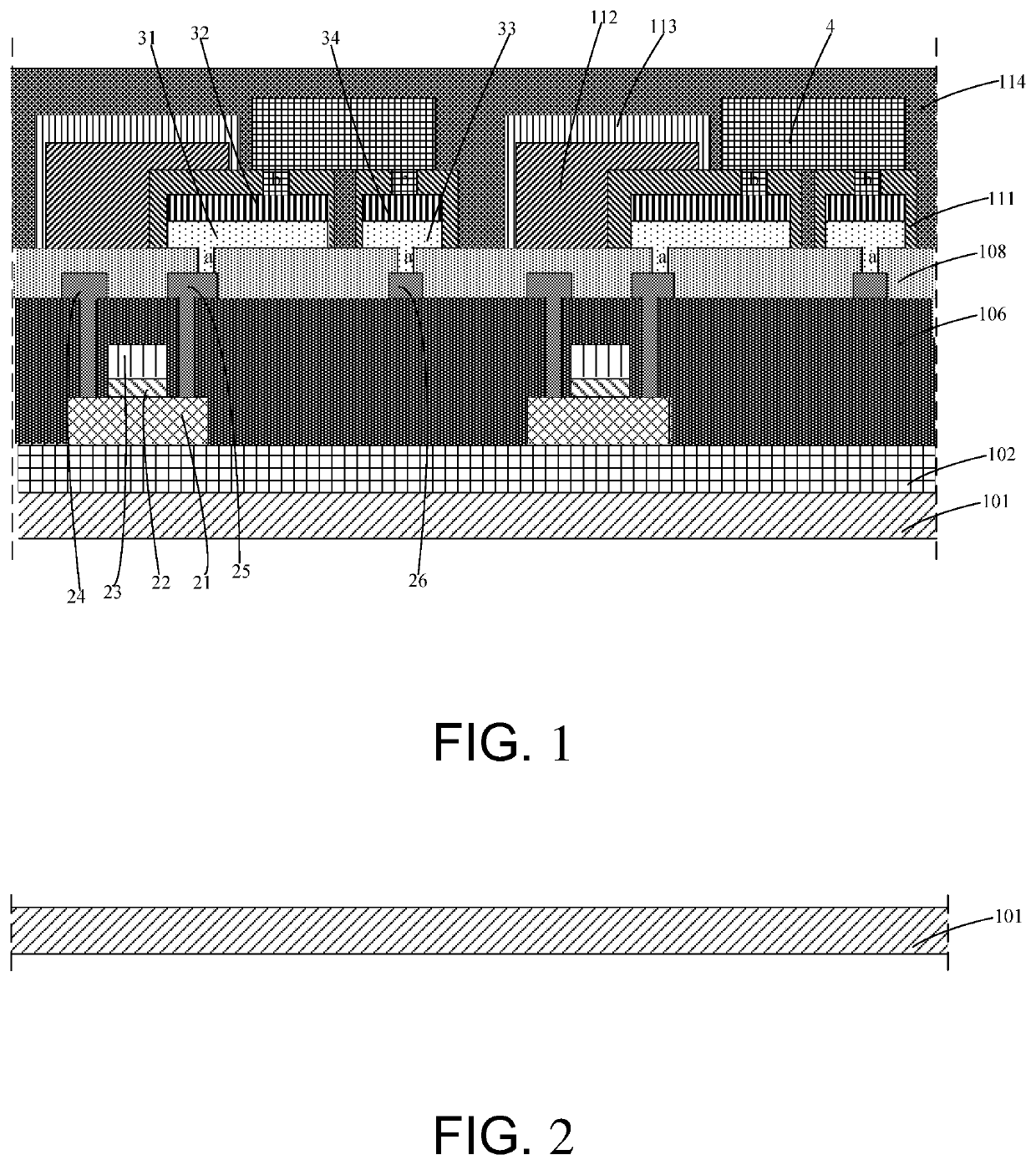

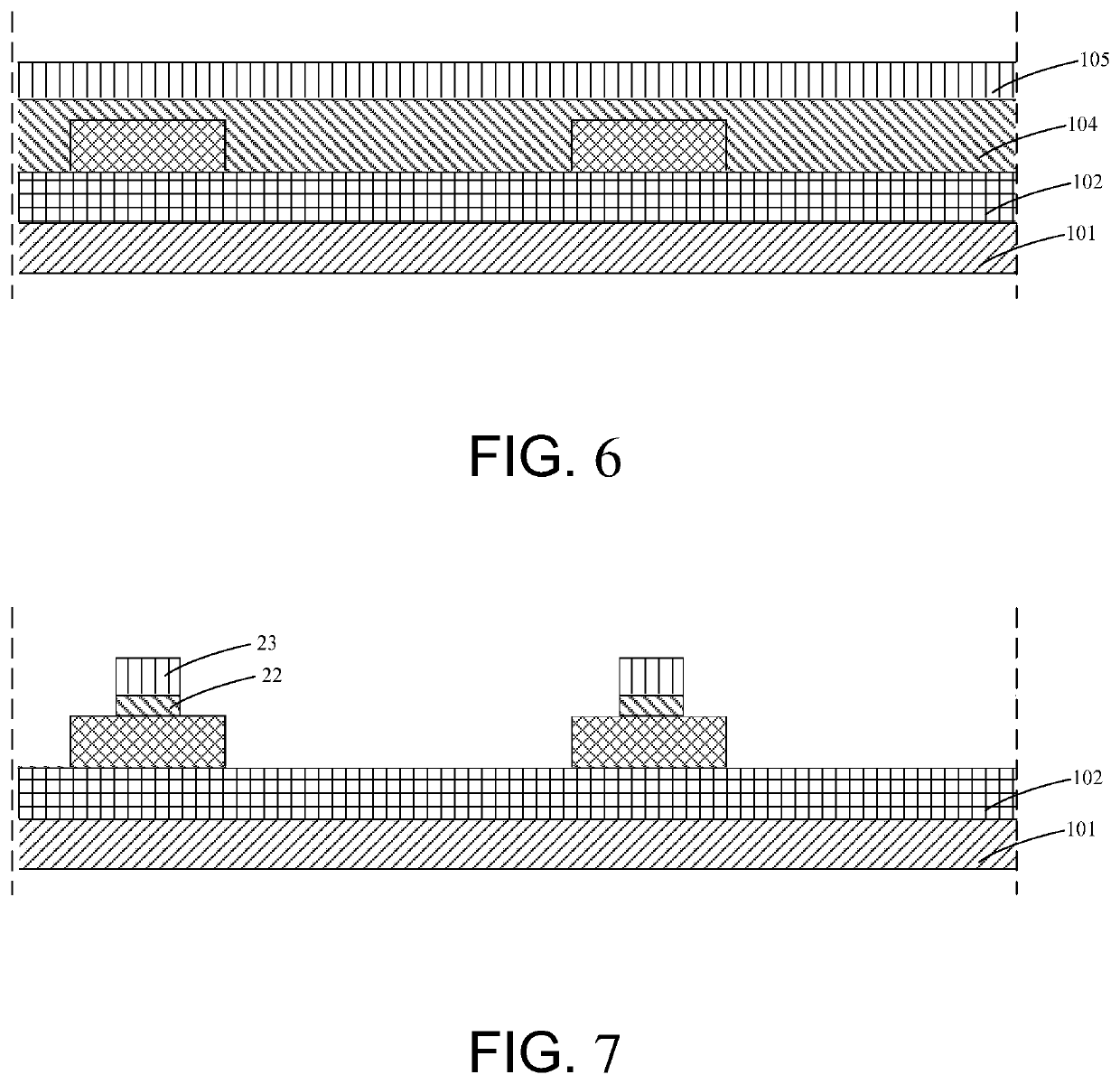

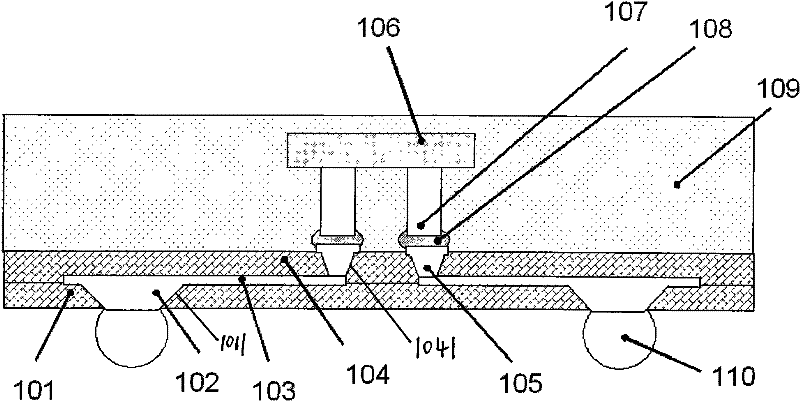

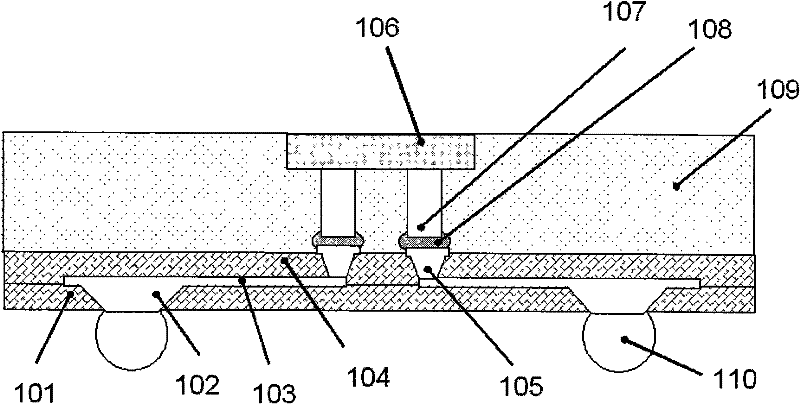

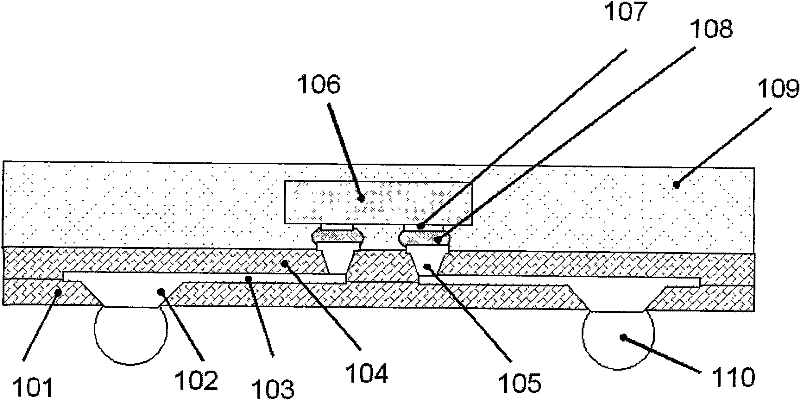

Wafer level fan-out chip packaging structure

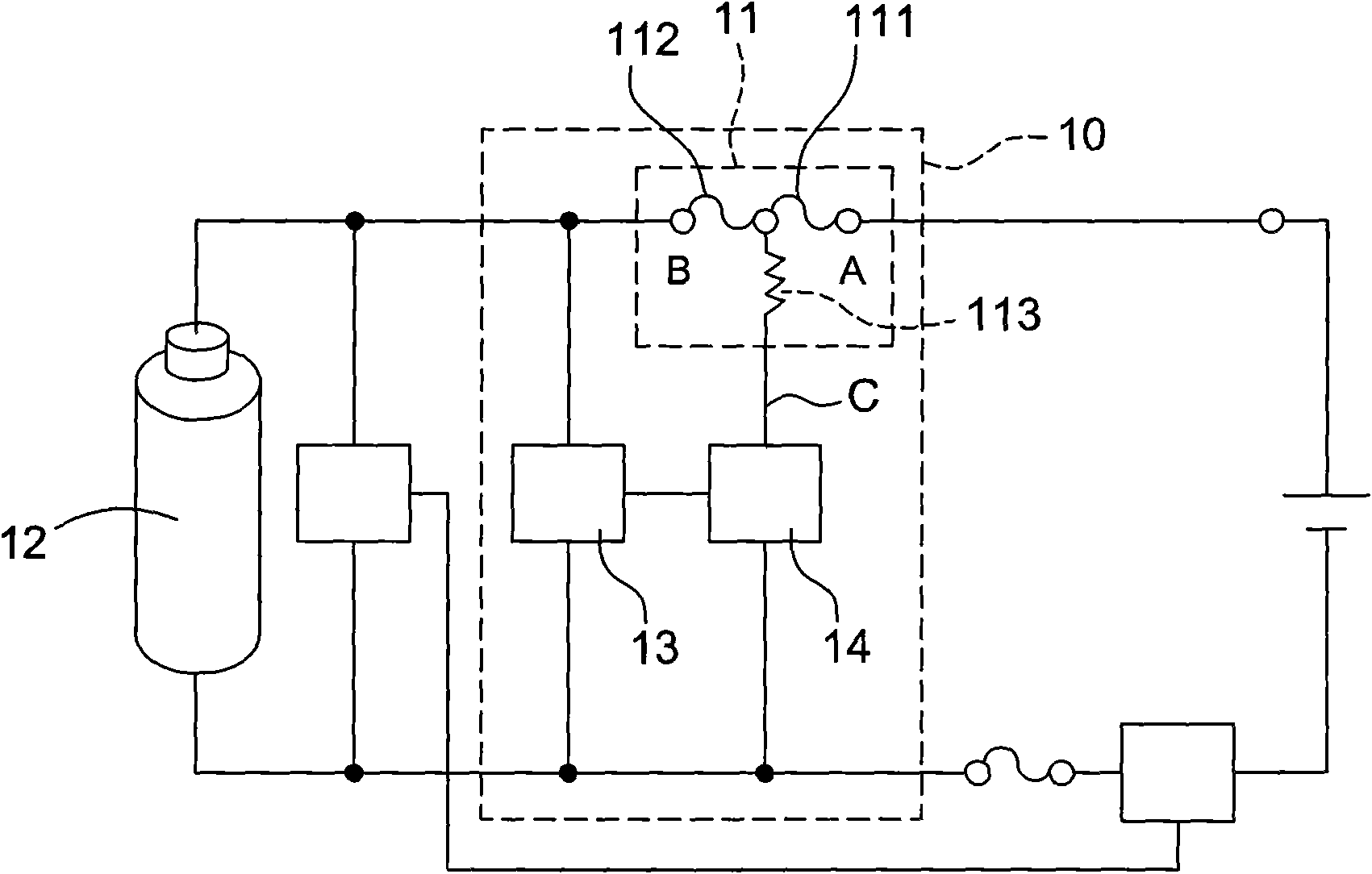

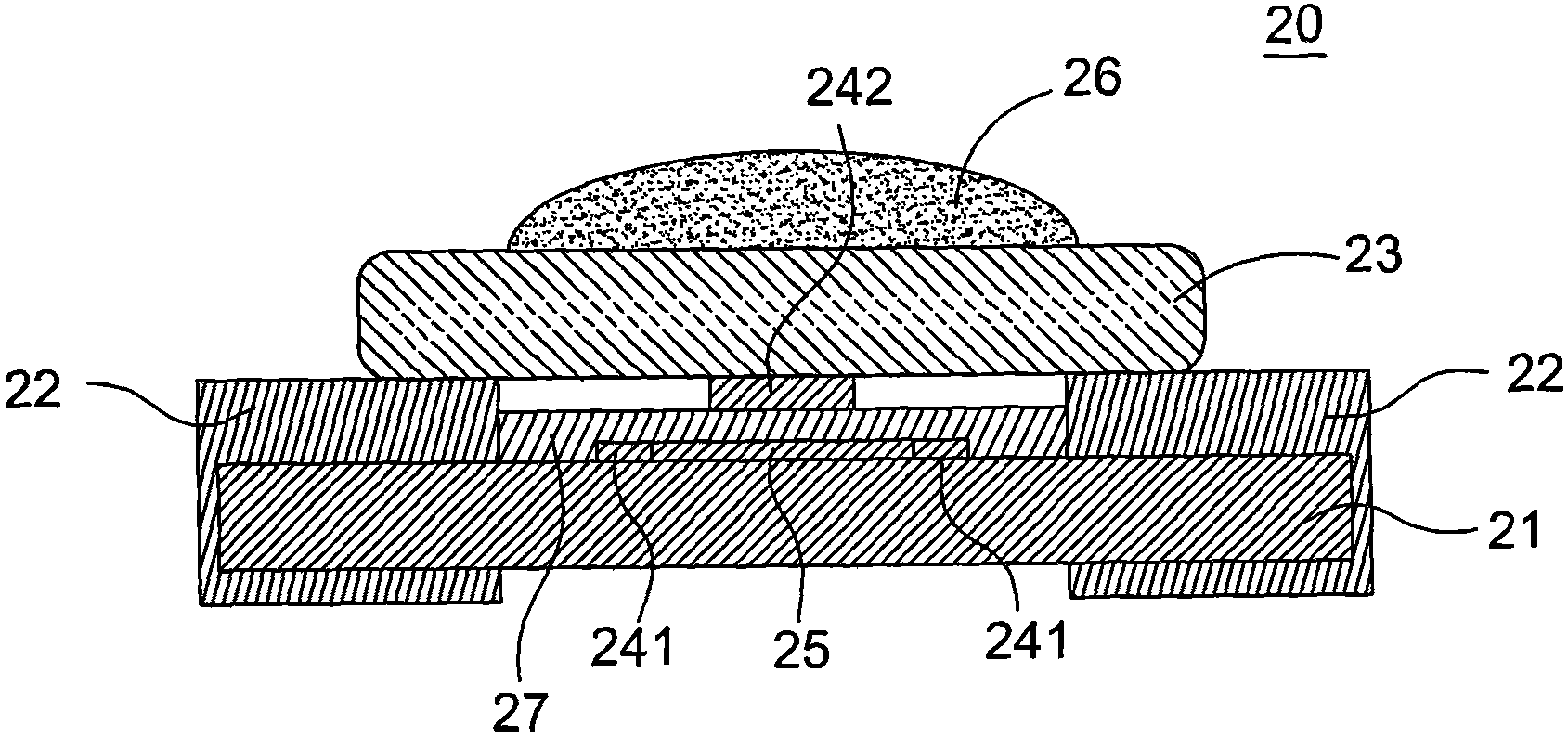

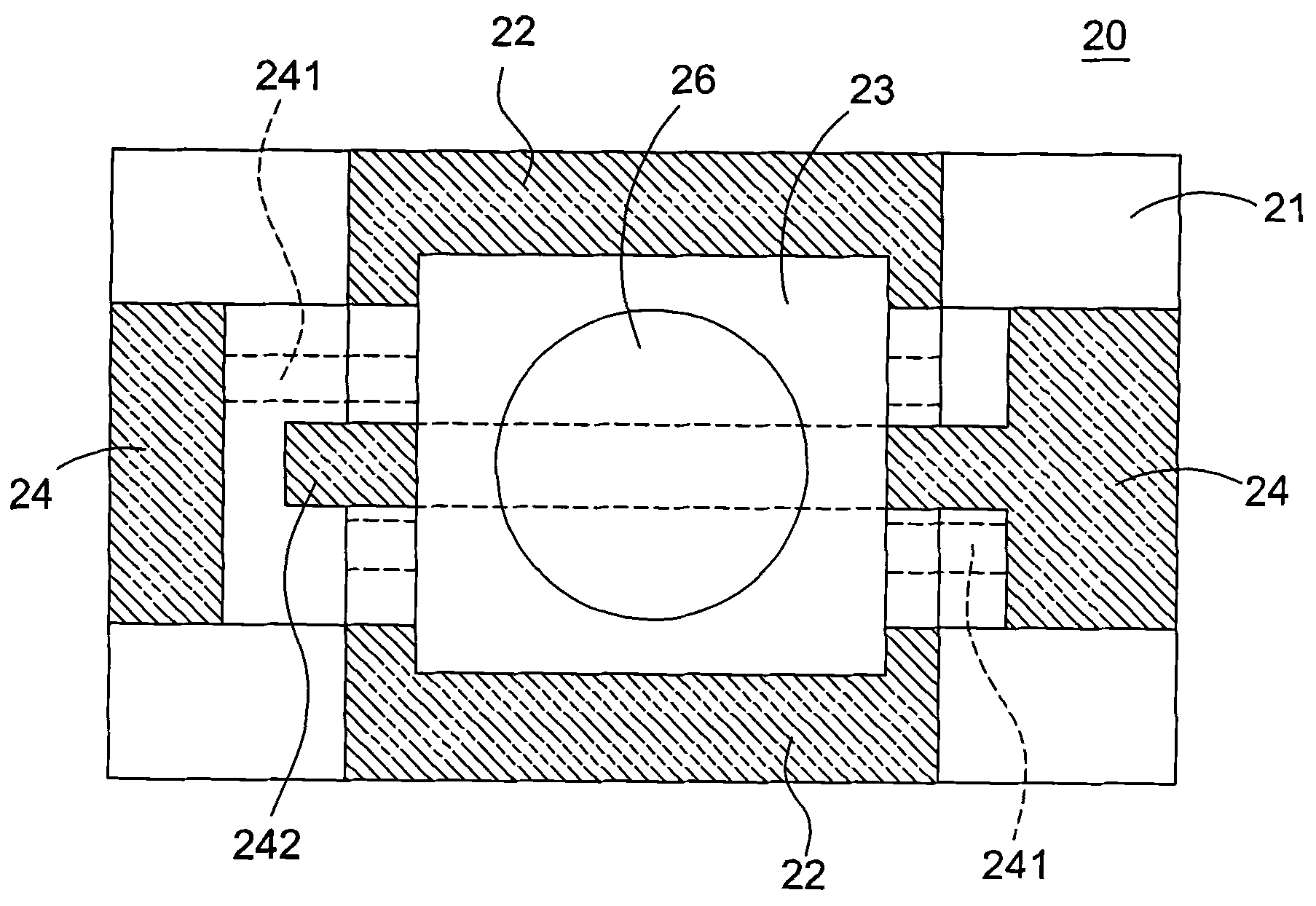

ActiveCN101604674ALower packaging costsSolve chip shiftSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringDielectric layer

The invention relates to a wafer level fan-out chip packaging structure, comprising a film dielectric layer I (101), a photoetching pattern opening I (1011) is formed on the film dielectric layer I (101), a metal electrode (102) and a re-wiring metal routing wire (103) which are connected with a base plate end are arranged on the photoetching pattern opening and the surface of the film dielectric layer I (101), a photoetching pattern opening I (1011) is formed on the film dielectric layer I, a film dielectric layer II (104) is covered on the surface of the metal electrode, the surface of the re-wiring metal routing wire, and the surface of the film dielectric layer I which are connected with the base plate end, and a photoetching pattern opening II (1041) is formed on the film dielectric layer II; a metal electrode (105) connected with a chip end is arranged on the photoetching pattern opening II, a chip (106), a metal column / metal salient point (107) and a welding flux are arranged on the metal electrode connected with the base plate end in an inverting way, so as to form a wafer with an inverted chip, packaging material (109) is injected on the surface of the wafer, and a welding ball salient point (110) is arranged on the metal electrode (102) connected with the base plate end. The packaging is low, has a carrying function and can well solve the problem that the chip is shifted in the technological process.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING

Folding type planar three-phase open transformer core

InactiveCN105469950AHigh mechanical strengthEasy to loosenTransformers/inductances magnetic coresTransformerButt joint

The invention discloses a folding type planar three-phase open transformer core. The folding type planar three-phase open transformer core comprises a transformer core body provided with an L-shaped interlocking structure, wherein the transformer core body is assembled by two completely identical one-phase cores serving as inner rings and a large one-phase core serving as the outer ring, and the section of the assembled core body is in the shape of an inscribed polygon of a circle, or a circle (R type), or a rectangle or a long circle; a one-frame core is composed of a plurality of sets of rectangular open material straps arranged in a rectangular corner area, the butt joints of the openings of the material straps are located at the two ends of an upper yoke, the two bevels of the rectangle and the upper ends of two stems. The folded core stems and the yoke are interlocked, so that the mechanical strength of the core is improved. Therefore, the core has the advantages of being low in consumption, low in noise, high in sudden short circuit resistance and high in production efficiency.

Owner:齐侠

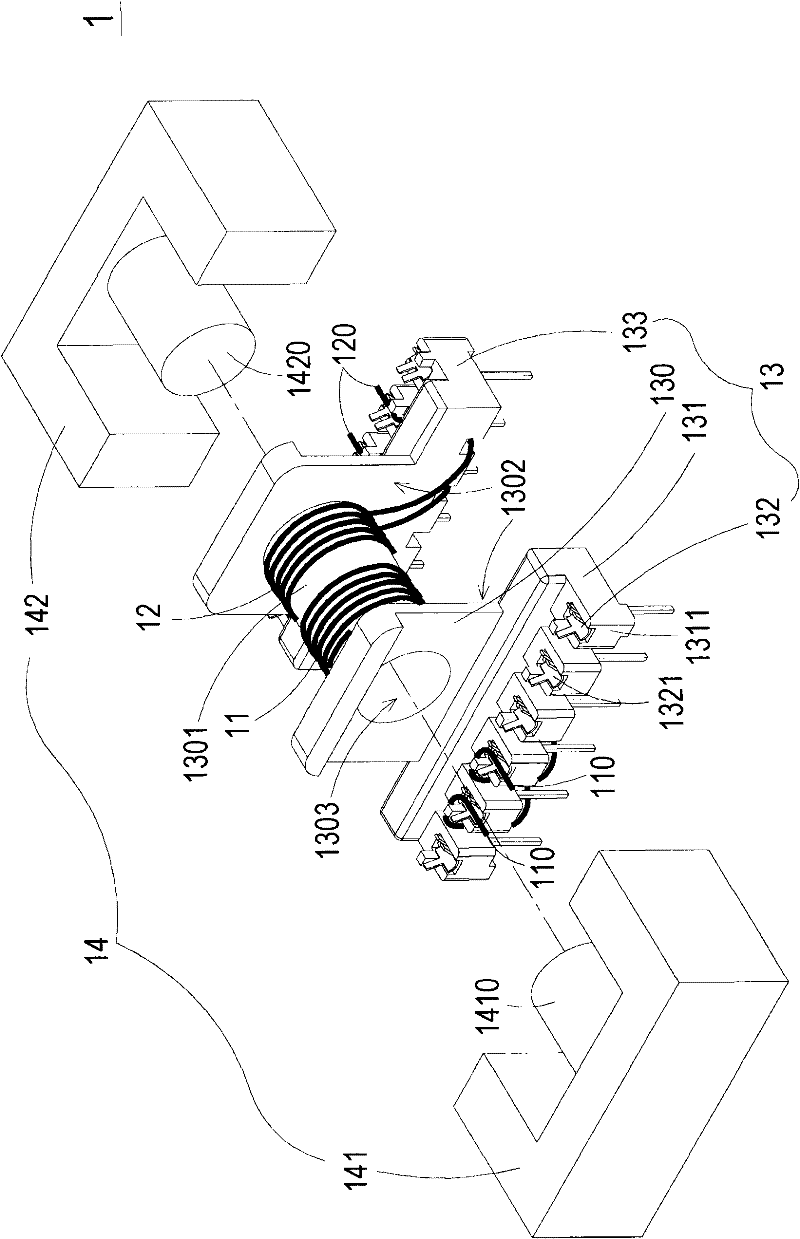

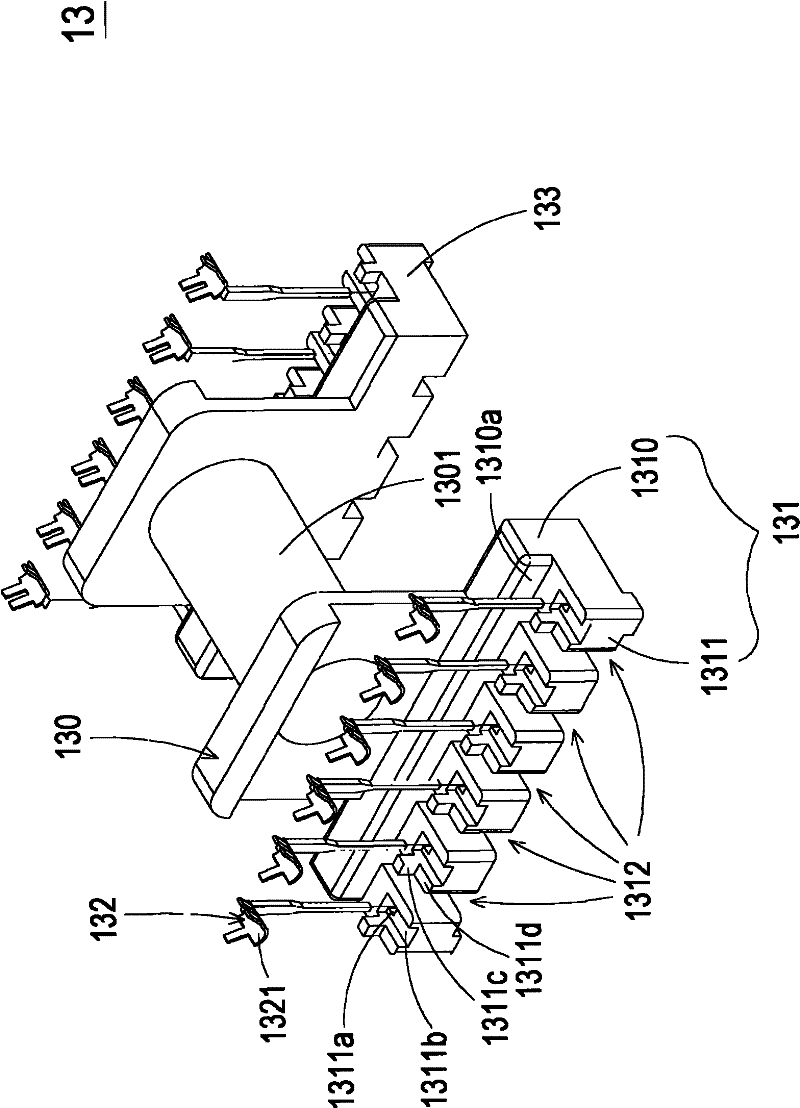

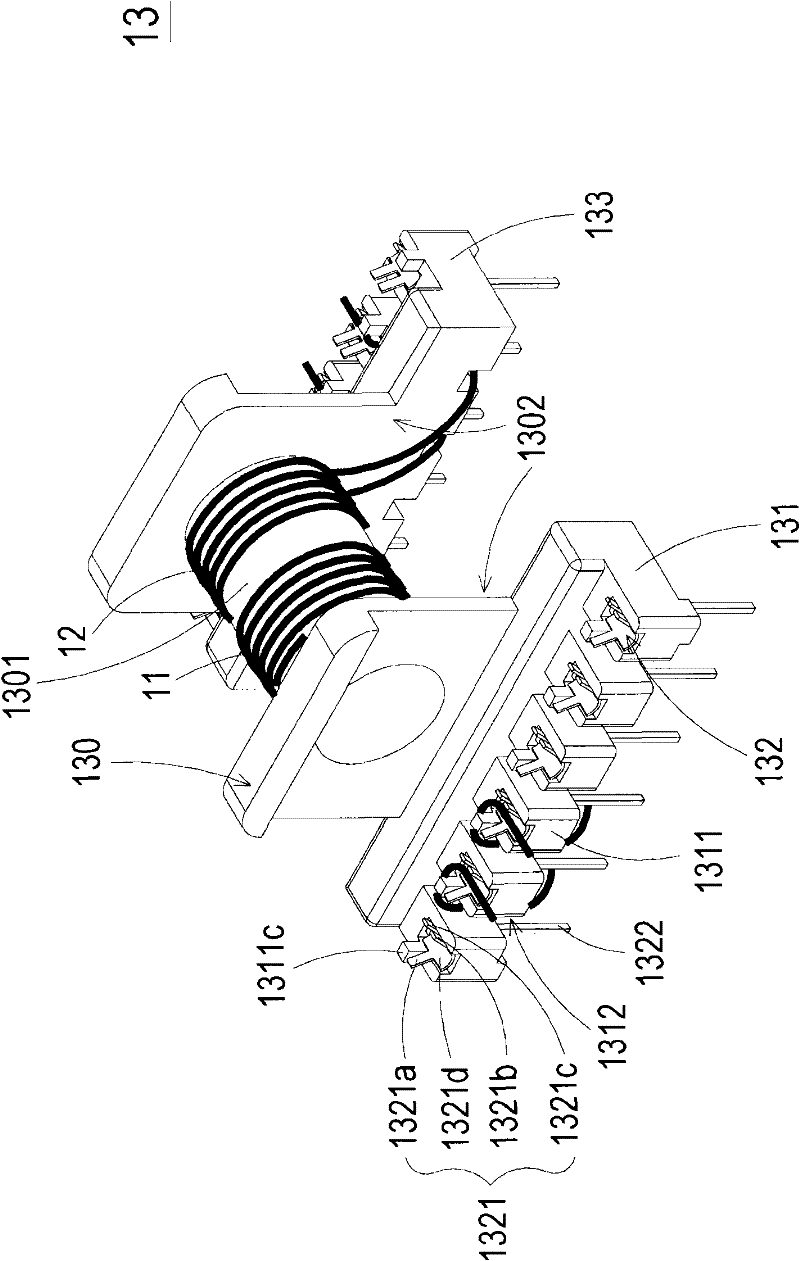

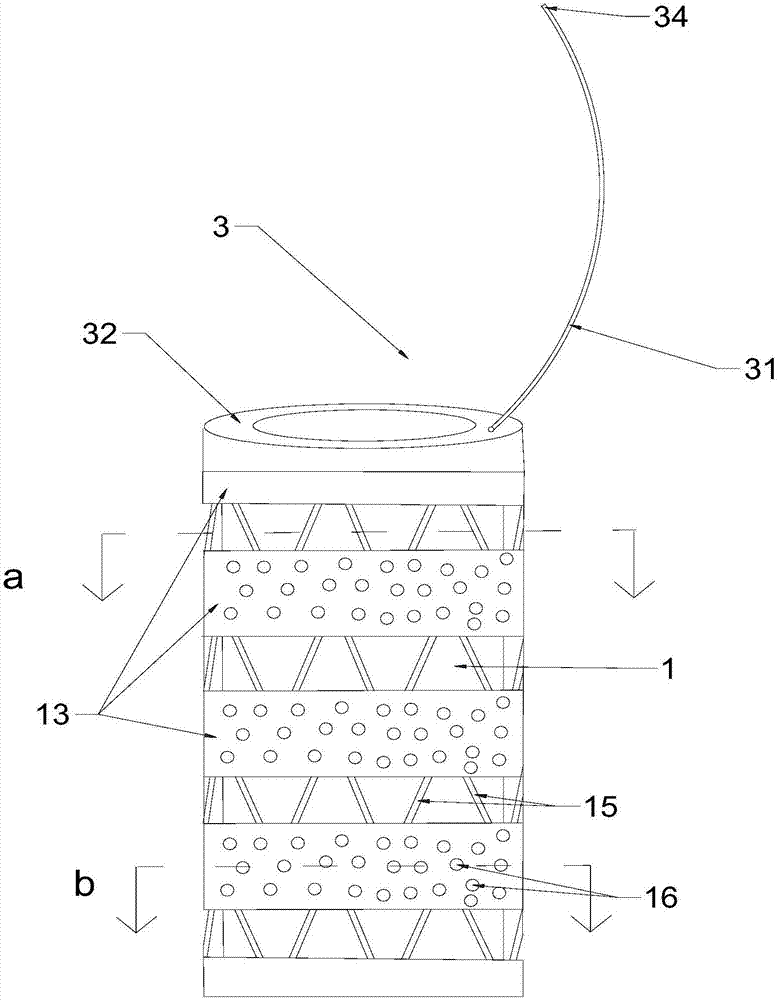

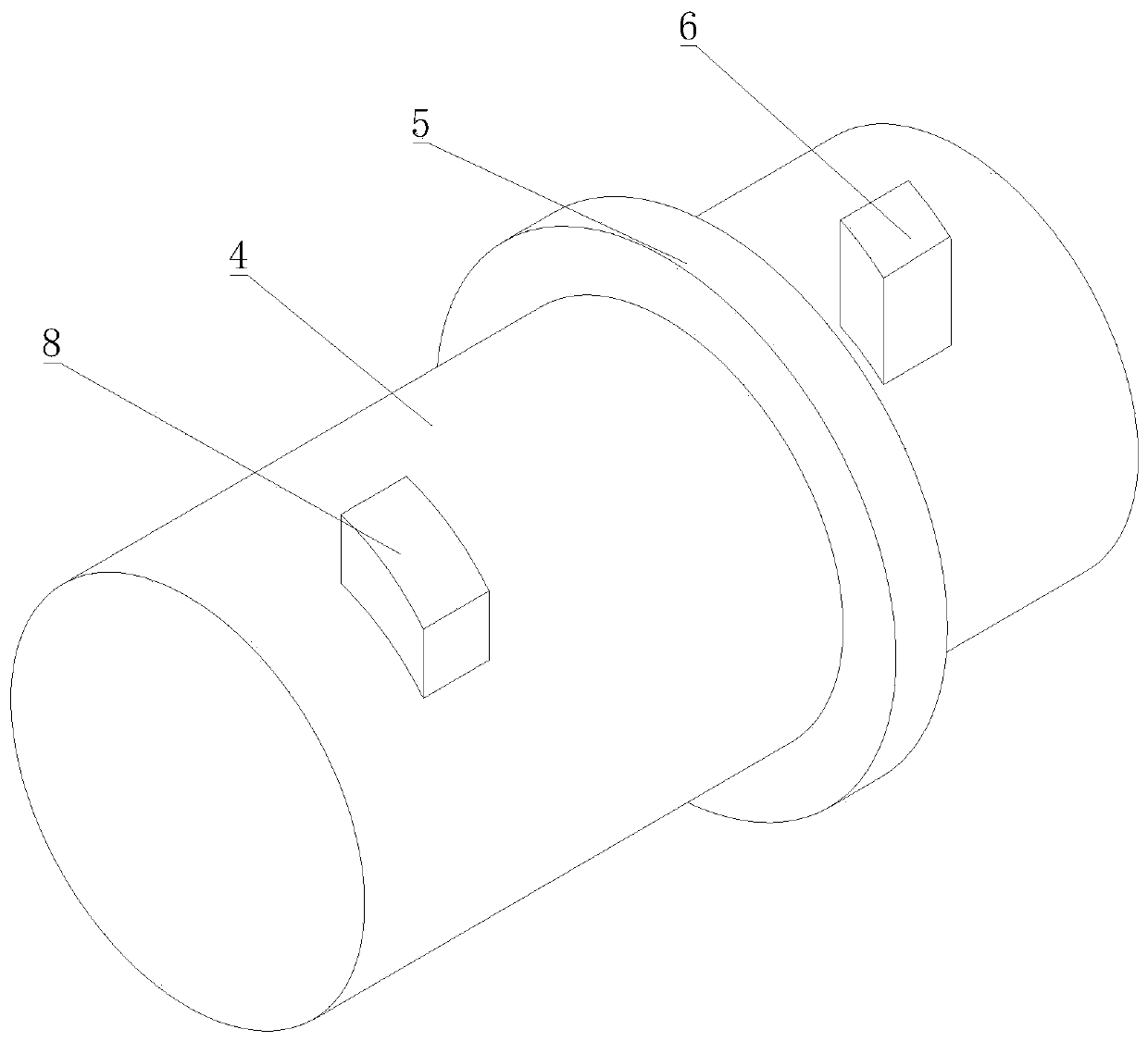

Reel and transformer utilizing same

InactiveCN102237184ASolve the shiftSave man hoursTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses a transformer and a reel. The transformer comprises at least one primary winding, at least one secondary winding, the reel and a magnetic core group, wherein the reel comprises a reel body, a first pin seat and a plurality of clamping pins; the reel body is provided with at least one winding area where the primary windings and the secondary windings are wound; the first pin seat is arranged at the bottom of the reel body; the plurality of clamping pins are arranged on the first pin seat; each clamping pin is provided with a clamping part; the clamping parts are used for clamping outgoing parts of the primary windings or the secondary windings onto the first pin seat; and at least a part of the magnetic core group is arranged in the reel. The transformer has the following beneficial effects: the pins are not easy to deform; the wires are easy to arrange; the wire arrangement time is reduced; and the problem of poor tinning during the welding of the pins can be avoided.

Owner:DELTA ELECTRONICS INC

Protection assembly

ActiveCN102468645ASolve process problemsSolve the shiftEmergency protective circuit arrangementsOvervoltageOvercurrent

A protection assembly comprises: a substrate, two first electrodes, a metal layer with a low melting point and an auxiliary layer. The first electrodes are arranged on two opposite sides of the substrate respectively. The metal layer with the low melting point is arranged on the first electrodes. The auxiliary layer is formed on the metal layer with the low melting point. A liquid phase point temperature of the auxiliary layer is lower than the liquid phase point temperature of the metal layer with the low melting point. And the liquid phase point temperature of the auxiliary layer is not lower than the temperature which is obtained by subtracting 25 degree from a maximum temperature of a reflow soldering technology. In the prior art, scaling powder has a gasification or shift problem in the reflow soldering technology. By using the protection assembly of the invention, the above problem can be solved. When the protection assembly encounters an overcurrent or an overvoltage, a charging device or a battery can be effectively protected.

Owner:CYNTEC

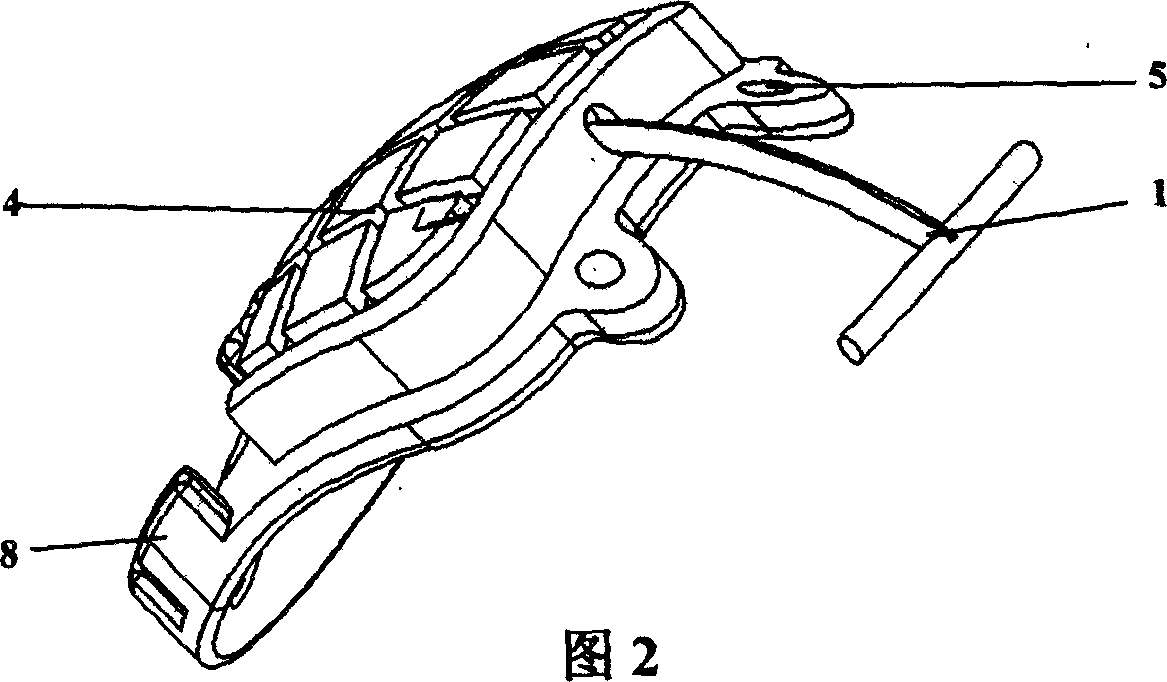

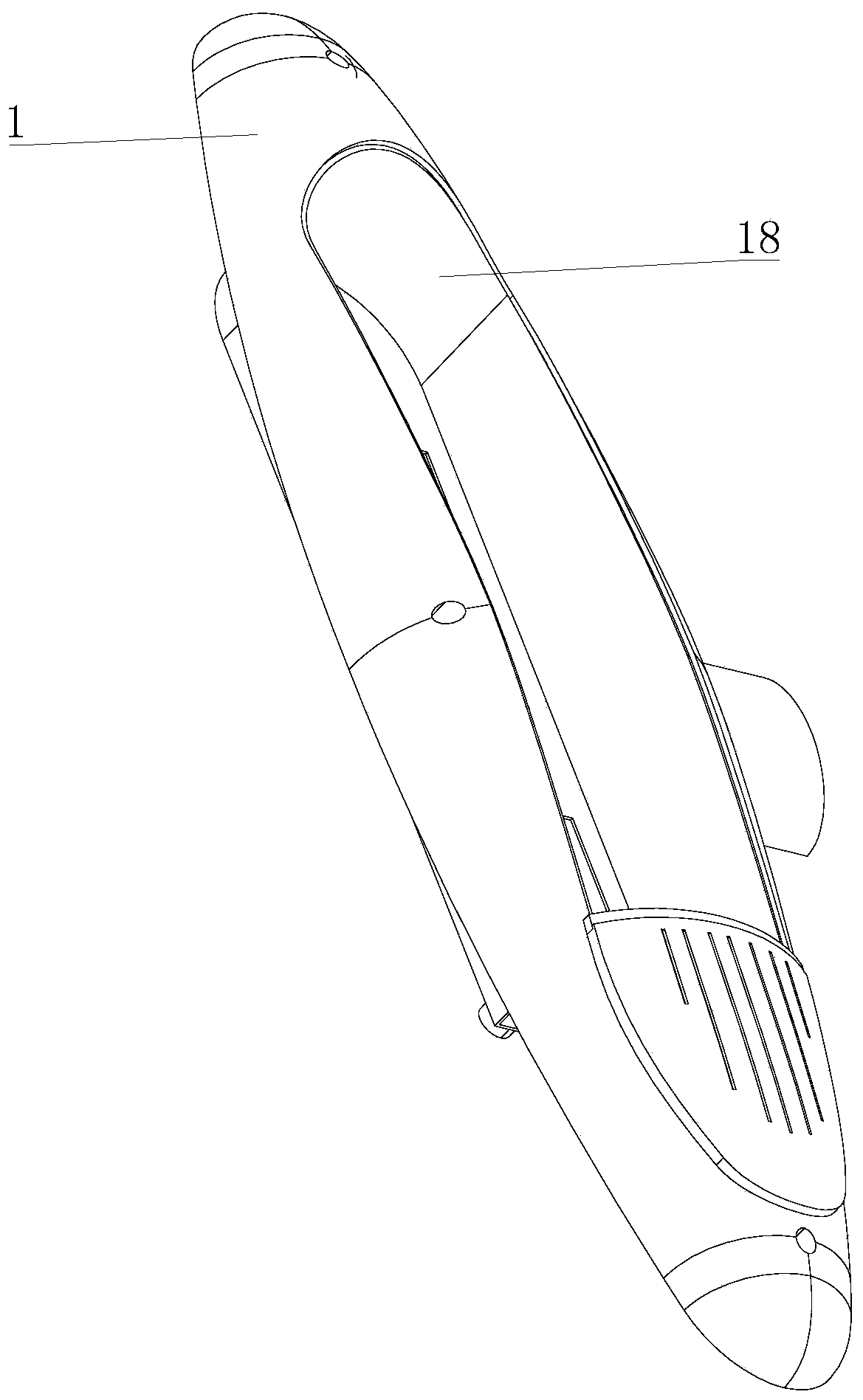

Drug-injectable anti-shift esophageal stent

ActiveCN107007378AAvoid displacementSolve the shiftMedical devicesOesophagiDrug injectionDrug Storage

The invention relates to a drug-injectable anti-shift esophageal stent which comprises an esophageal bracket body and a liner membrane. The drug-injectable anti-shift esophageal stent further comprises a drug injection device for injecting a drug into the esophagus; the esophageal stent body comprises a plurality of bracket units which are connected through suture lines and closed skirt membranes; the liner membrane is located in the esophageal stent body, the lower end edge of the liner membrane extends outward radially to form an annular bottom membrane, and an annular drug storage chamber is formed between the liner membrane and the inner wall of the esophagus; the drug-injection device is separately connected to the upper end edges of the liner membrane and the esophageal stent body and communicates with the drug storage chamber. The drug-injectable anti-shift esophageal stent provided by the invention can effectively solve the problem of shift of the esophageal stent and also can directly inject the drug into the diseased region of the esophagus through the drug injection device.

Owner:令狐恩强 +1

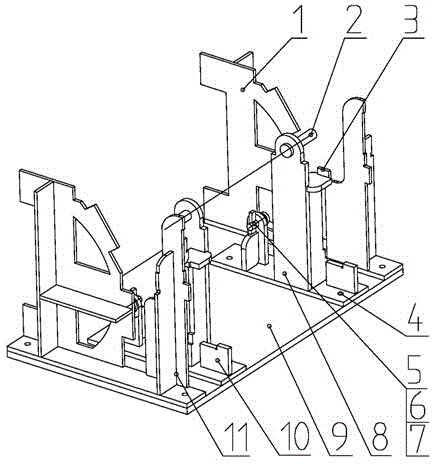

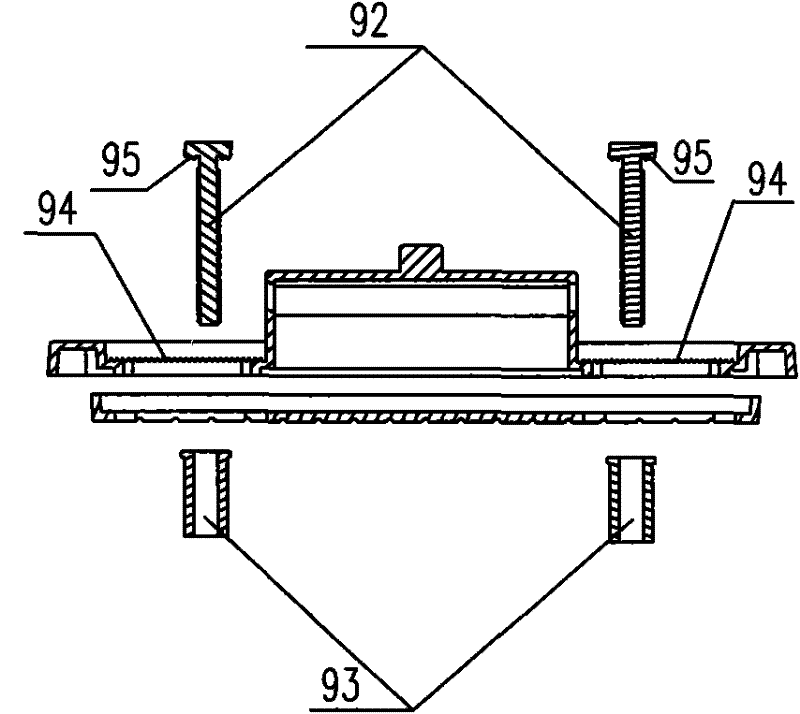

Splice welding locating device for front frame of loading machine

InactiveCN104476075AReduce utilizationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameReference surface

The invention discloses a splice welding locating device for a front frame of a loading machine. The splice welding locating device for the front frame of the loading machine comprises a pedestal, and the pedestal is provided with a left outer locating frame, a left inner locating frame, a right inner locating frame and a right outer locating frame. The splice welding locating device for the front frame of the loading machine uses locating shaft and locating surface locating principles, the position precision is guaranteed when splice welding a workpiece, each size is guaranteed through locating, and the measuring tool use is reduced; by means of a pneumatic system, the labor intensity is reduced, the locating is reliable, and the product quality and production efficiency are improved; by means of a measurement reference surface on a fixture, a worker can more conveniently and precisely measure each size of the workpiece. The splice welding locating device for the front frame of the loading machine avoids the displacement and size deviation in the welding process and enables the efficiency to be improved, the cost to be lowered, the quality to be guaranteed and the resource to be saved, and the structure is simple.

Owner:LIUZHOU JINMAO MACHINERY

Closet with plate cover including built-in atomizing and spraying system

InactiveCN101474049ASolve the weight problemSolve the shiftFlushing devicesBathroom coversSpray nozzleEngineering

The invention discloses a toilet bowl with a built-in spraying and sprinkling system lid. A toilet bowl body is equipped with a toilet seat cover assembly which comprises a fixed base which is fixed on the toilet bowl body, a toilet seat which is coaxially arranged on the fixed base and a toilet seat cover, wherein, the toilet seat cover is equipped with a spraying agent pot fixing structure for positioning a common spraying agent pot which can sterilize and fragrant atmosphere, a trigger mechanism which triggers a spray nozzle to act by opening and closing of the toilet seat cover is arranged opposite to a spray nozzle of the spraying agent pot, and an outlet of the spray nozzle faces inner bottom of the toilet seat in a horizontal state when the spray nozzle is triggered. The toilet bowl is designed for home and cultivation of personal hygiene consciousness, and can force users to sterilize the toilet bowl before and after using the toilet bowl, thus the users can enjoy a fragrant and clean toilet at any time. The toilet bowl has the advantages of simple and novel structure, simple and convenient manufacture, low manufacturing cost and easy popularization.

Owner:开平雅琪塑胶机械模具厂

Wafer level fan-out chip packaging method

ActiveCN101604638BAchieve connectionAvoid displacementSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingMetal electrodes

The invention relates to a wafer level fan-out chip packaging method, comprising the following technological processes: a stripping foil and a film dielectric layer I are sequentially covered on the surface of the wafer of a carrier, a photoetching pattern opening I is formed on the film dielectric layer I; a metal electrode and a re-wiring metal routing wire which are connected with a base plateend are arranged on the photoetching pattern opening and the surface thereof, a film dielectric layer II is covered on the surface of the metal electrode, the surface of the re-wiring metal routing wire, and the surface of the film dielectric layer I which are connected with the base plate end, and a photoetching pattern opening II is formed on the film dielectric layer II; a metal electrode connected with a chip end is arranged on the photoetching pattern opening II, after a chip is arranged on the metal electrode connected with the chip end in an inverting way, the injection molding of packaging material and solidification are carried out, so as to form a packaging body with plastic-packaging material; the wafer of the carrier and the stripping foil are separated from the packaging bodywith plastic-packaging material, so as to form a plastic-packaging wafer; a welding sphere back returns to form a welding ball salient point; cutting is carried out by uniwafers for forming the finalstructure of the fan-out chip. The method has low cost and a carrying function, and can well solve the problem that the chip is shifted in the technological process.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

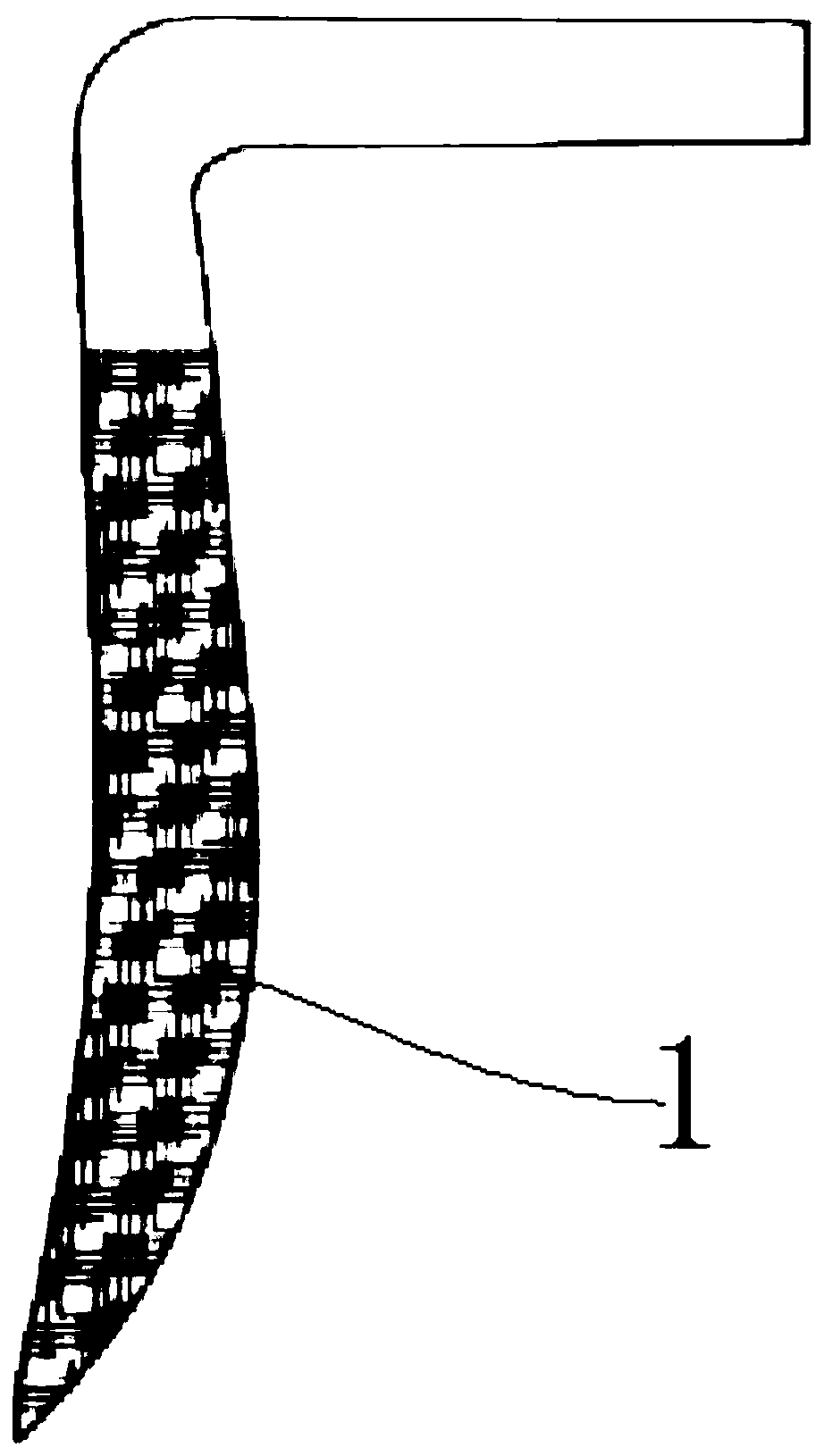

Fabrication method of composite nasal bridge prosthesis with surface micropores

The invention discloses a fabrication method of a composite nasal bridge prosthesis with surface micropores. The method comprises the following steps: step 1: sandblasting the mold surface of siliconerubber nasal bridge prosthesis to form a certain roughness of 1-3 [mu]m; step 2: putting the silicone rubber into a mold cavity for vulcanization, taking out the product after vulcanization, trimmingthe excess residual edges, making a silicone rubber nasal bridge prosthesis with a certain roughness on the surface of the nasal back, and the roughness being 1-3 [mu]m; and step 3: cutting the expanded polytetrafluoroethylene strip with scissors according to the size and shape of the back surface of the silicone rubber nasal bridge prosthesis. The beneficial effect is that the composite nasal bridge prosthesis with surface micropores prepared by the present invention can allow tissue cells to grow in, the defects of postoperative prosthesis displacement caused by the smooth surface of silicagel, light transmission, etc., are effectively solved, and the therapeutic effect of the nasal bridge prosthesis is improved.

Owner:周锋杰

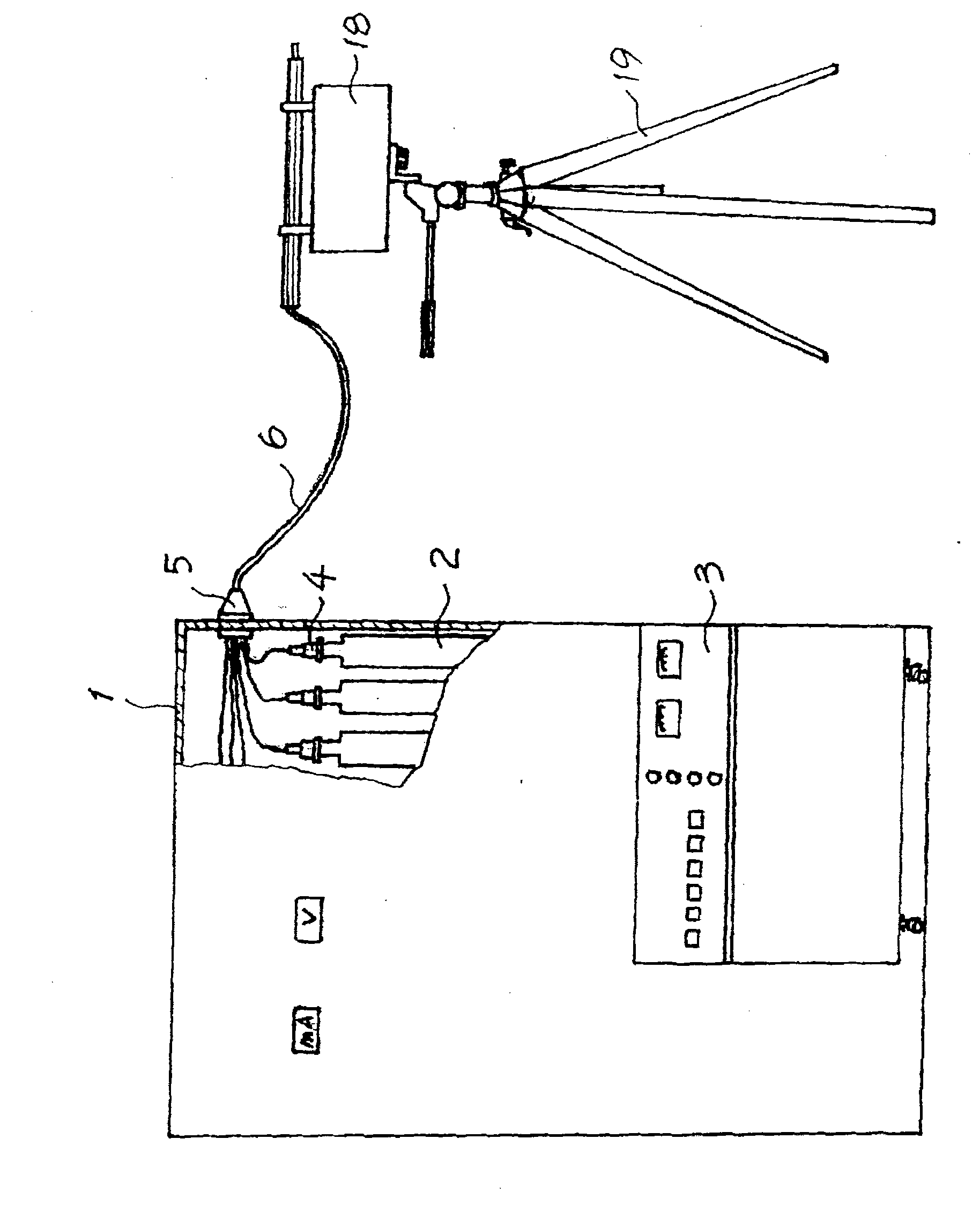

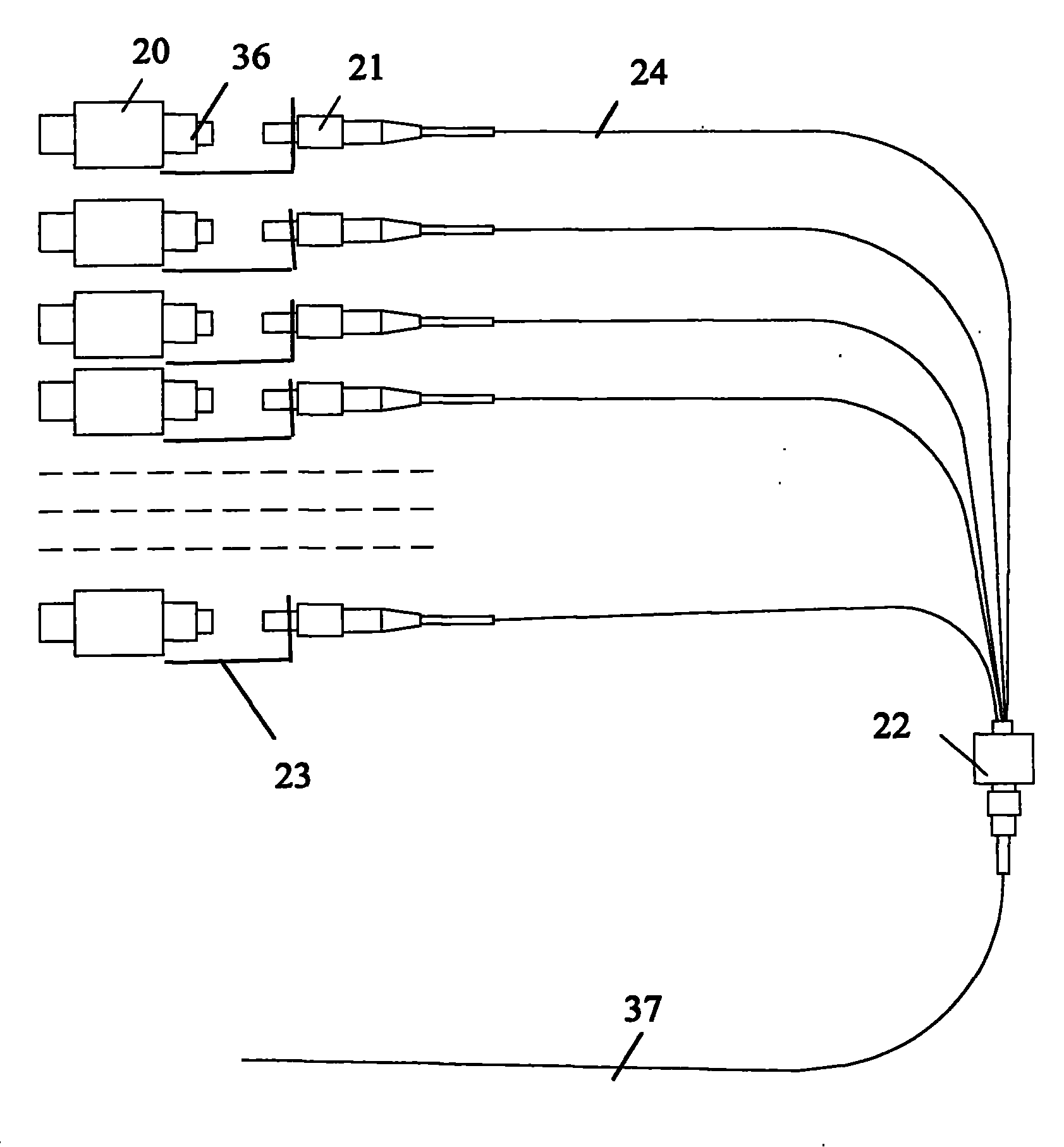

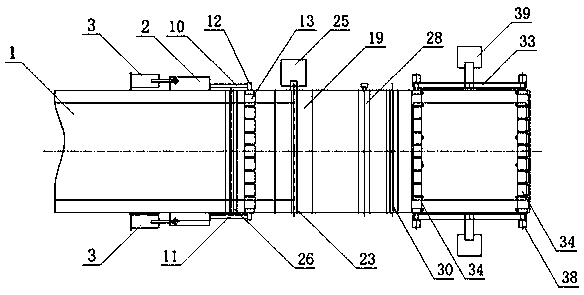

Multi-light guide gain amplification laser equipment

ActiveCN101837168ASolve looseSolve the shiftLaser arrangementsRadiation therapyCoupling efficiencyEnergy loss

The invention relates to multi-light guide gain amplification laser equipment comprising a plurality of laser devices, a plurality of socket type photoconductive coupling devices and a socket type multi-light guide gain amplification device, wherein the laser devices are connected with the socket type multi-light guide gain amplification device by supporting plates; and the socket type photoconductive coupling devices are connected with the socket type multi-light guide gain amplification device by a single optical fiber. The multi-light guide gain amplification laser equipment has a structure that through a photoconductive coupling seat, the socket type photoconductive coupling devices are installed on the supporting plates connected with the laser devices so that once optical fibers on the socket type photoconductive coupling devices need to be replaced, just lock nuts of the coupling devices need to be loosened; and after reinstalled, the socket type photoconductive coupling devices do not need to be adjusted, thereby being convenient for operation, saving labor and time and leading the work efficiency to be high. Besides, by utilizing a positioning fastening device and lock nuts, the socket type multi-light guide gain amplification device leads multiple beam optical fibers to be in direct butt joint with the single beam optical fiber, and any other optical lens are not needed, thereby avoiding energy loss and increasing the coupling efficiency.

Owner:TIANJIN LEIYI LASER TECH

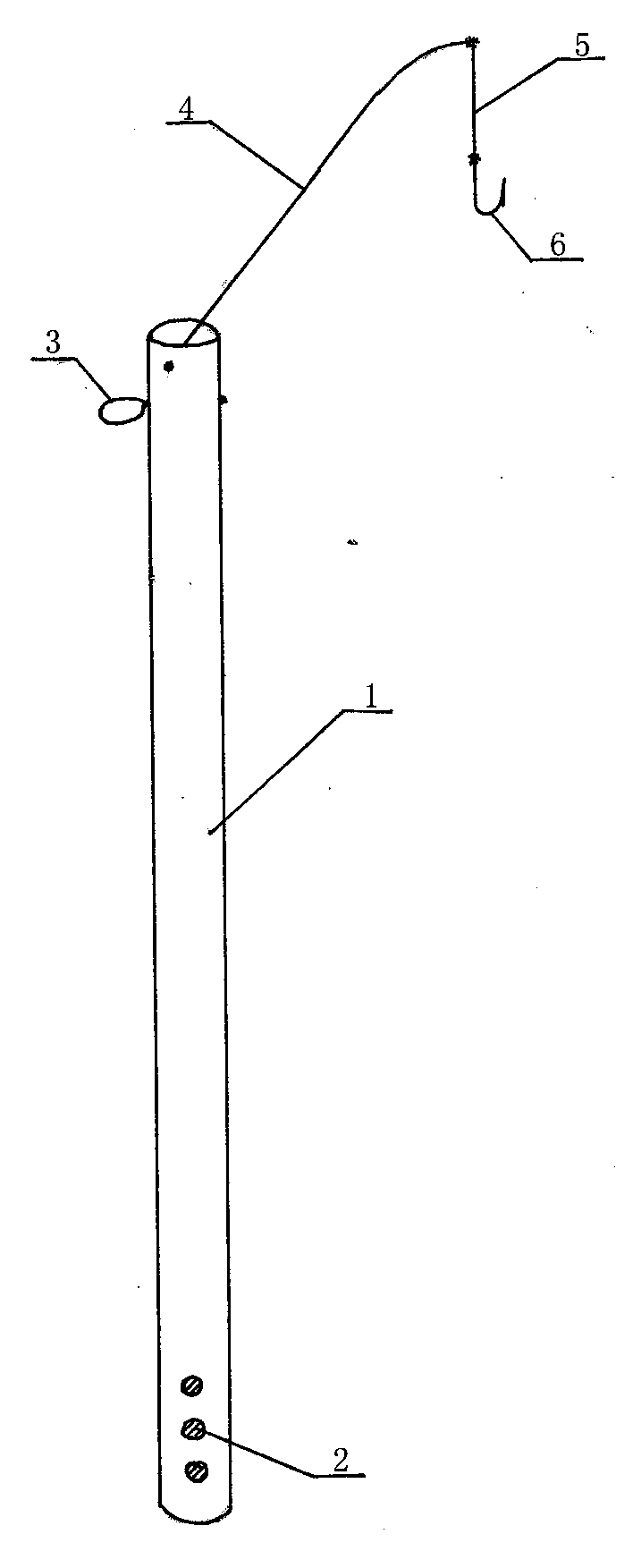

Stand-out hook

A stand-out hook is characterized in that a main thread connecting ring is arranged at the upper end of a hollow tube, a support rod inclining up is arranged at the upper end of the hollow tube, the outer end of the support rod is fixedly connected with a fishhook through a sub-line, and two to five strip weights transversely passing the inside of the hollow tube are fitted to the lower end of the hollow tube. In case of a tided beach, hook strangling rarely occurs to the stand-out hook during beach fishing, and no shifting of the stand-out hook due to c wind or waterflow occurs.

Owner:张有振

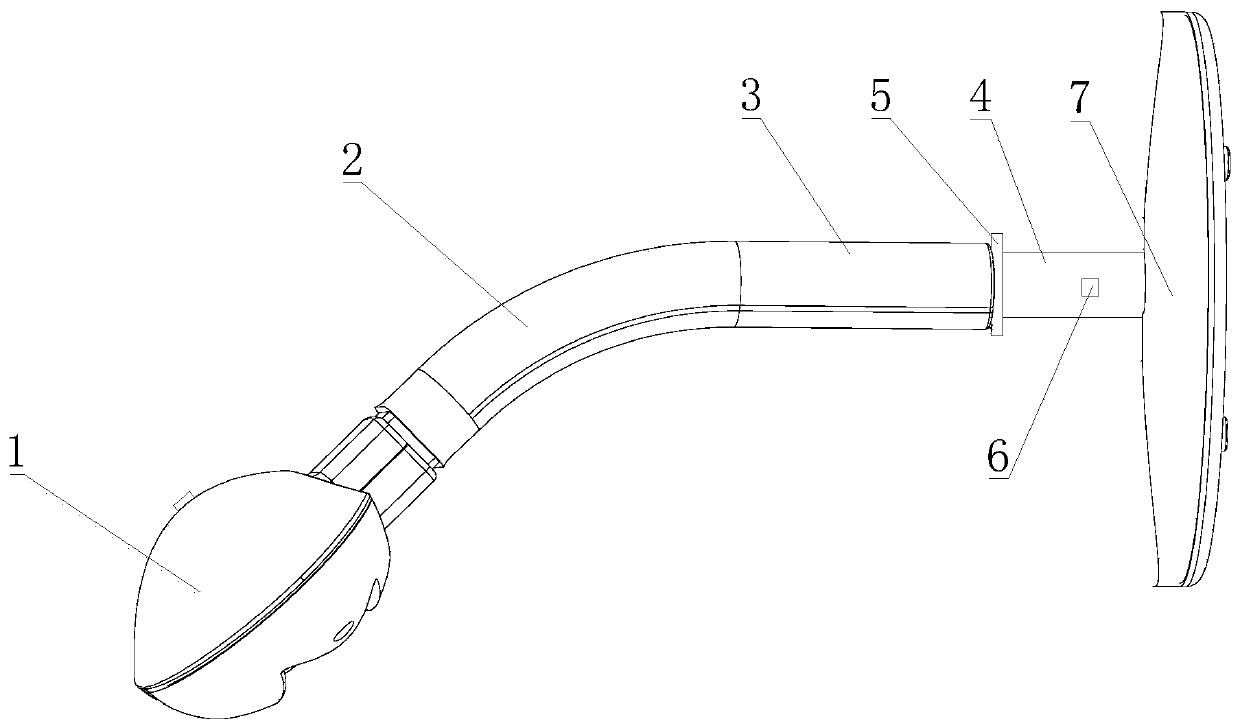

LED lamp for student learning

InactiveCN110953499AQuick installationEasy to installLighting support devicesLighting heating/cooling arrangementsLED lampMaterials science

The invention discloses an LED lamp for student learning. The LED lamp comprises an LED lamp body, a movable adjusting rod and a plate body, the LED lamp body is connected with one end of the movableadjusting rod; the other end of the movable adjusting rod is connected with a first mounting pipe; wherein the first mounting pipe is of a hollow structure with an opening in one end, a second mounting pipe is of a hollow mechanism, one end of the second mounting pipe is inserted into the opening end of the first mounting pipe and connected with the first mounting pipe through the mounting mechanism, the other end of the first mounting pipe is mounted on the plate body, and the plate body is mounted on a wall body; the driving assembly is located at the end close to the plate body, the limiting assembly is located in the position close to the first mounting pipe, the outer wall of the second mounting pipe is sleeved with the positioning sleeve, the driving assembly is connected with the limiting assembly through the sliding rod, and limiting holes matched with the limiting assembly are symmetrically formed in the inner wall of the first mounting pipe; the desk has the advantages that the desk is convenient to mount and demount on the wall, the occupied area of the desk top is reduced, mosquito repelling and heat dissipation are combined, and the working efficiency of the desk top and the wall is greatly improved.

Owner:马鞍山三投光电科技有限公司

Toilet having built-in spraying system plate cover

InactiveCN101933781BSolve the weight problemSolve the shiftFlushing devicesBathroom coversSpray nozzleConsciousness

The invention discloses a toilet having a built-in spraying system plate cover. A toilet plate cover assembly is arranged on a toilet body and comprises a fixed base fixed on the toilet body, a seat retainer coaxially arranged on the fixed base and a toilet plate cover, wherein the toilet plate cover is provided with a spray tank fixing structure for positioning and holding a common sterilizing scented spray tank; a trigger mechanism which is opened and closed by the toilet plate cover to trigger a nozzle to act is arranged at a position opposite to the nozzle of the spray tank; and the outlet of the nozzle points to the inner bottom of the seat retainer in a horizontal state when the nozzle is triggered. The toilet is designed for culturing household and personal health consciousness, can force a user to sterilize and spray the toilet before and after the use of the toilet so as to ensure that all people can enjoy a scented and sanitary washroom at any time, and has the advantages ofsimple and novel structure, simple and convenient manufacturing, low cost and easy popularization.

Owner:开平雅琪塑胶机械模具厂

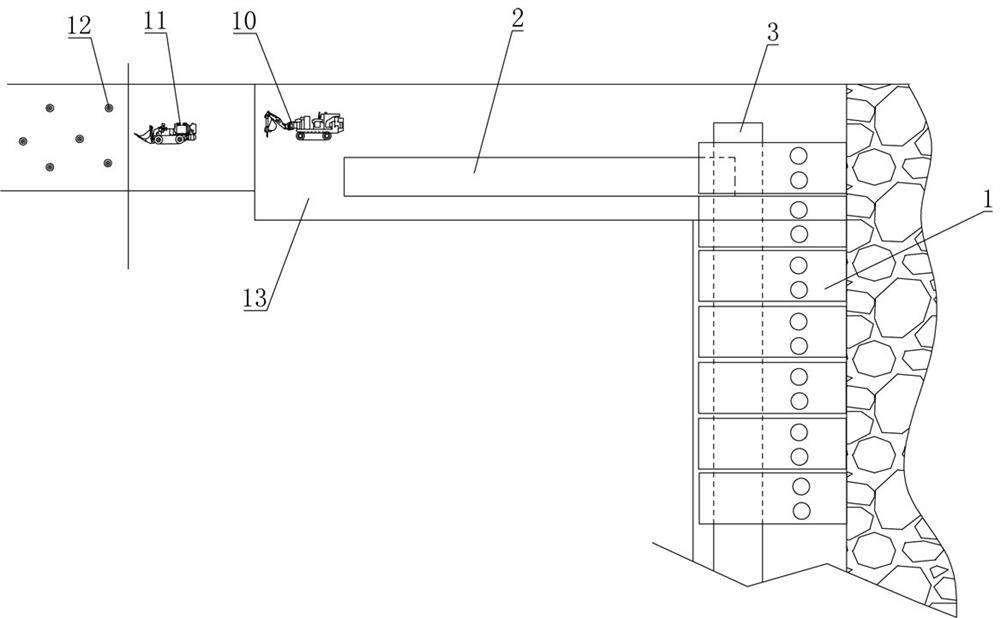

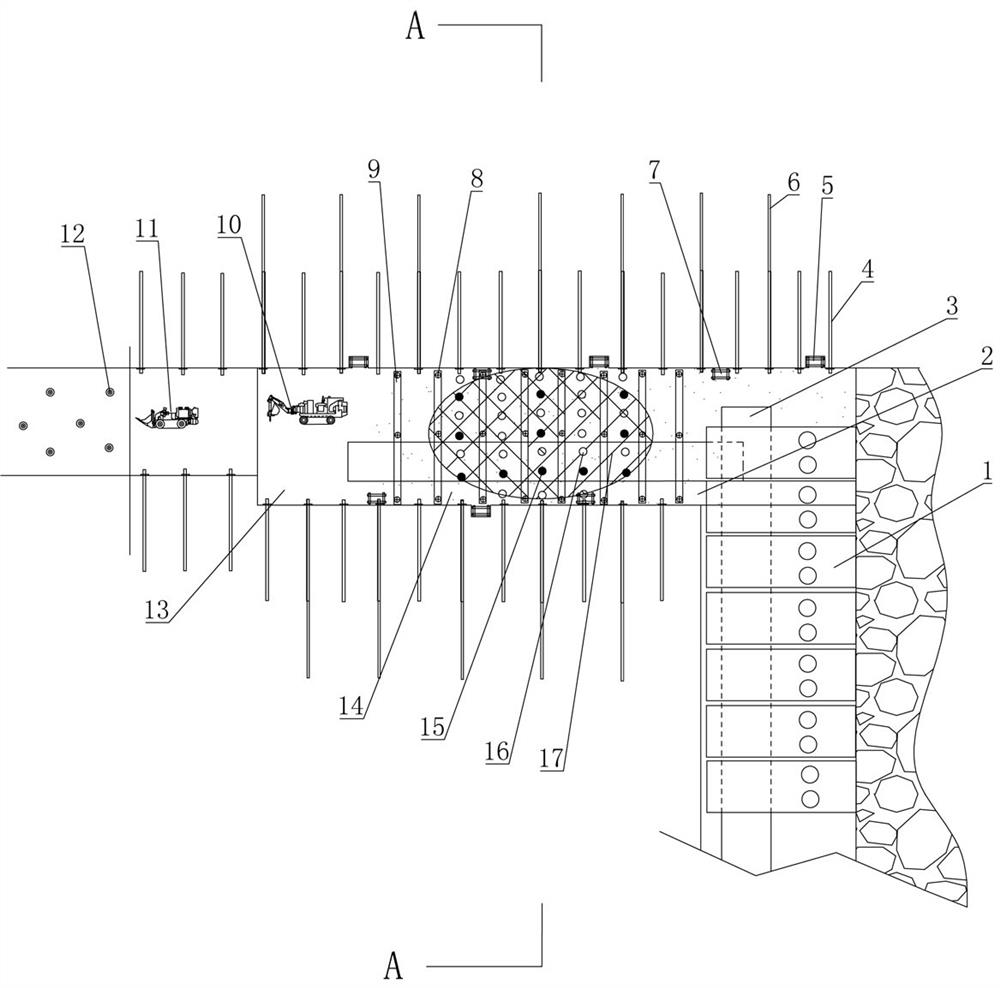

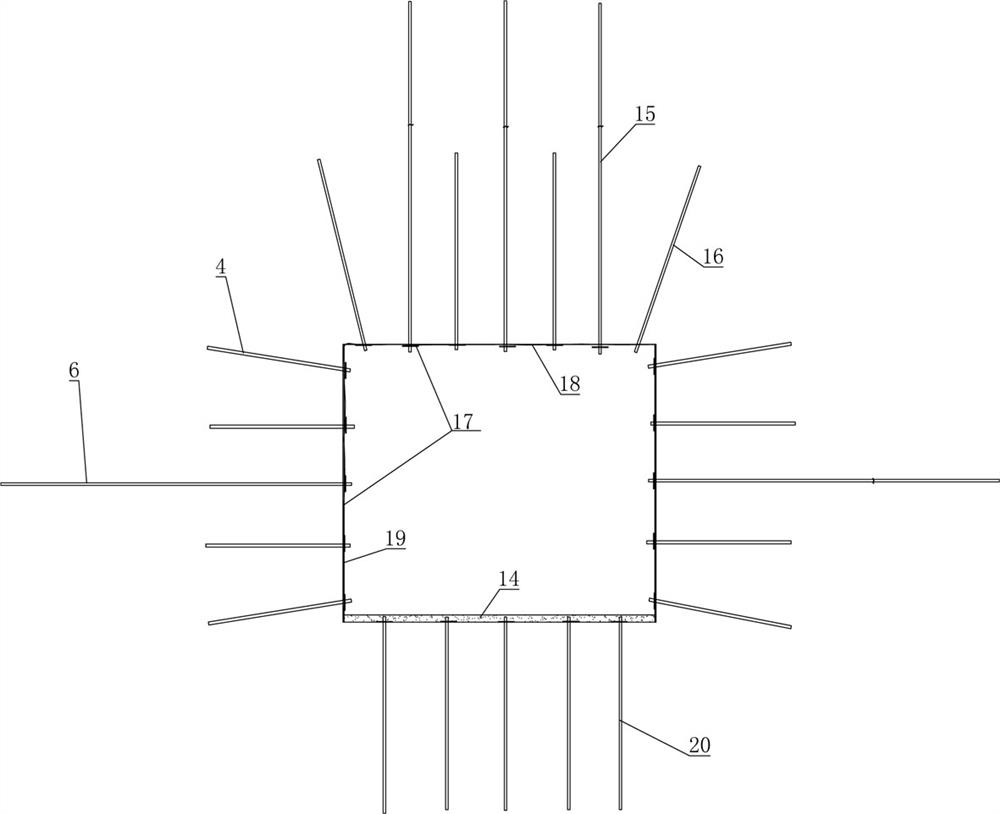

A method for the expansion and support of return airway in soft rock working face of coal mine

ActiveCN109779652BIncreased propulsion speedReduce labor intensityUnderground chambersTunnel liningMining engineeringArchitectural engineering

The invention relates to a method for repairing and supporting an air return roadway in a soft rock working face of a coal mine. Firstly, a side loader is used to pull the bottom, and a roadway repair machine is used to carry out roof lifting and side expansion; For the net cable, use steel sheds for inclined miners, trough-type wooden piles and sided wooden piles to strengthen the support; for the U-shaped steel shed support section roadway, re-erect U-shaped steel sheds, trough-type wooden piles and sided wooden piles for reinforcement support. The present invention is mainly to solve the problem that during the mining process of the working face, under the influence of mine pressure and mining disturbance, the soft rock roadway will converge on the roof, floor and two sides, resulting in a significant reduction in the roadway section, affecting ventilation, pedestrians, material transportation, Coal transportation and other problems. Through the implementation of the present invention, it is also possible to effectively reduce the repair frequency of the roadway, reduce the labor intensity of workers, and increase the advancing speed of the working face, which is of great significance for improving the economic benefits of the mine.

Owner:李洪彪

Micro light emitting diode display panel, method for fabricating same, and display device

ActiveUS20210398952A1Reduce the impactThreshold voltage shiftTransistorSolid-state devicesDisplay deviceActive layer

The present disclosure provides a micro light emitting diode display panel, a method for fabricating the same, and a display device comprising the same. The micro light emitting diode display panel includes an active layer, a gate insulating layer, a gate electrode, a source electrode, a drain electrode, a pixel electrode, a micro light emitting diode, and a gate insulating layer covering the active layer, the gate insulating layer, the gate electrode, the source electrode, and the drain electrode. The light shielding layer blocks light emitted by the micro light emitting diode from being incident on the thin film transistor, thereby reducing influence of the light emitted by the micro light emitting diode light on the thin film transistor.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Pedestal pan provided with plate cover with built-in spraying system

InactiveCN101933782ASolve the weight problemSolve the shiftFlushing devicesBathroom coversSpray nozzleEngineering

The invention discloses a pedestal pan provided with a plate cover with a built-in spraying system. A pedestal pan plate cover assembly is arranged on a pedestal pan body and comprises a fixed base fixed on the pedestal pan body, a toilet seat coaxially arranged on the fixed base and a pedestal pan plate cover, wherein the pedestal pan plate cover is provided with a spray tank fixing structure for locating a common sterilizing fragrance spray tank; a triggering mechanism which triggers a nozzle to activate by opening and closing of the pedestal pan plate cover is arranged correspondingly to the nozzle of the spray tank; and when the nozzle is in a triggering state, and the exit of the nozzle points to the bottom in the toilet seat in a horizontal state. The invention is designed for culturing the housing and personal hygiene consciousness and can force the user to sterilize the pedestal pan before and after using the pedestal pan so that the user and others can enjoy a fragrant and healthy toilet at any time. The pedestal pan has the advantages of simple and novel structure, simple and convenient manufacturing process, low cost and easy popularization.

Owner:开平雅琪塑胶机械模具厂

Micro light emitting diode display panel, method for fabricating same, and display device

ActiveUS11355478B2Reduce impactThreshold voltage shiftTransistorSolid-state devicesDisplay deviceActive layer

The present disclosure provides a micro light emitting diode display panel, a method for fabricating the same, and a display device comprising the same. The micro light emitting diode display panel includes an active layer, a gate insulating layer, a gate electrode, a source electrode, a drain electrode, a pixel electrode, a micro light emitting diode, and a gate insulating layer covering the active layer, the gate insulating layer, the gate electrode, the source electrode, and the drain electrode. The light shielding layer blocks light emitted by the micro light emitting diode from being incident on the thin film transistor, thereby reducing influence of the light emitted by the micro light emitting diode light on the thin film transistor.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

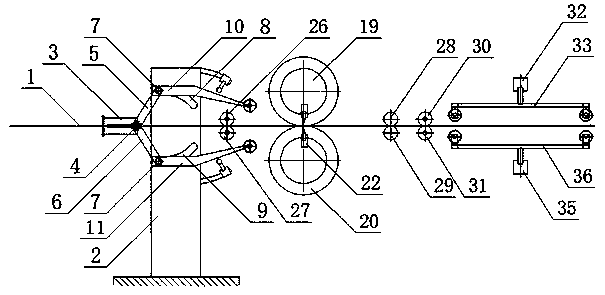

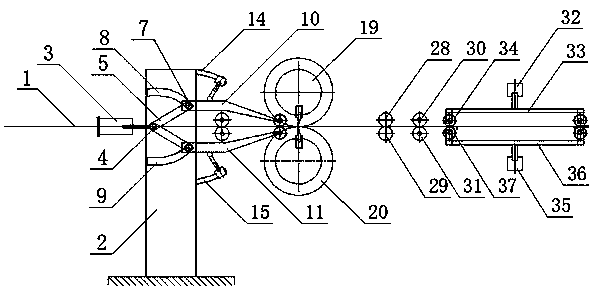

Woven bag continuous shearing and bag opening twisting device and processing technological method thereof

ActiveCN110315803ASolve the shiftPlay the role of auxiliary clamping and fixingBag making operationsPaper-makingEngineeringHot melt

The invention discloses a woven bag continuous shearing and bag opening twisting device and a processing technological method of the woven bag continuous shearing and bag opening twisting device. Thewoven bag continuous shearing and bag opening twisting device and the processing technological method of the woven bag continuous shearing and bag opening twisting device are characterized in that a left movement mechanism and a right movement mechanism are adopted to guarantee the restraint and press in the woven bag shearing process, telescopic cylinders can drive the movement mechanisms to moveat the same time, and an upper clamping transmission roller and a lower clamping transmission roller also play a role in assisting in clamping and fixing woven bags; an upper shearing roller and a lower shearing roller are arranged in the up-and-down direction, and rotate in the opposite directions at the same speed, and therefore the quick shearing operation of the woven bags is achieved by means of the high temperature and the shearing force on two shearing knives; and the two shearing knives are rotated to be separated, and therefore the situation that after the woven bags are molten, thewoven bags adhere to blades cannot exist, the shearing effect is improved, quick separation can be automatically achieved in the hot shearing process, the degree of automation is high, the damage to the notch edges cannot be caused, and the processing efficiency and the processing quality of the woven bags can be improved manyfold.

Owner:HUBEI UNIV OF TECH

Wafer level fan-out chip packaging structure

ActiveCN101604674BAchieve connectionAvoid displacementSemiconductor/solid-state device detailsSolid-state devicesMetal electrodesDielectric layer

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

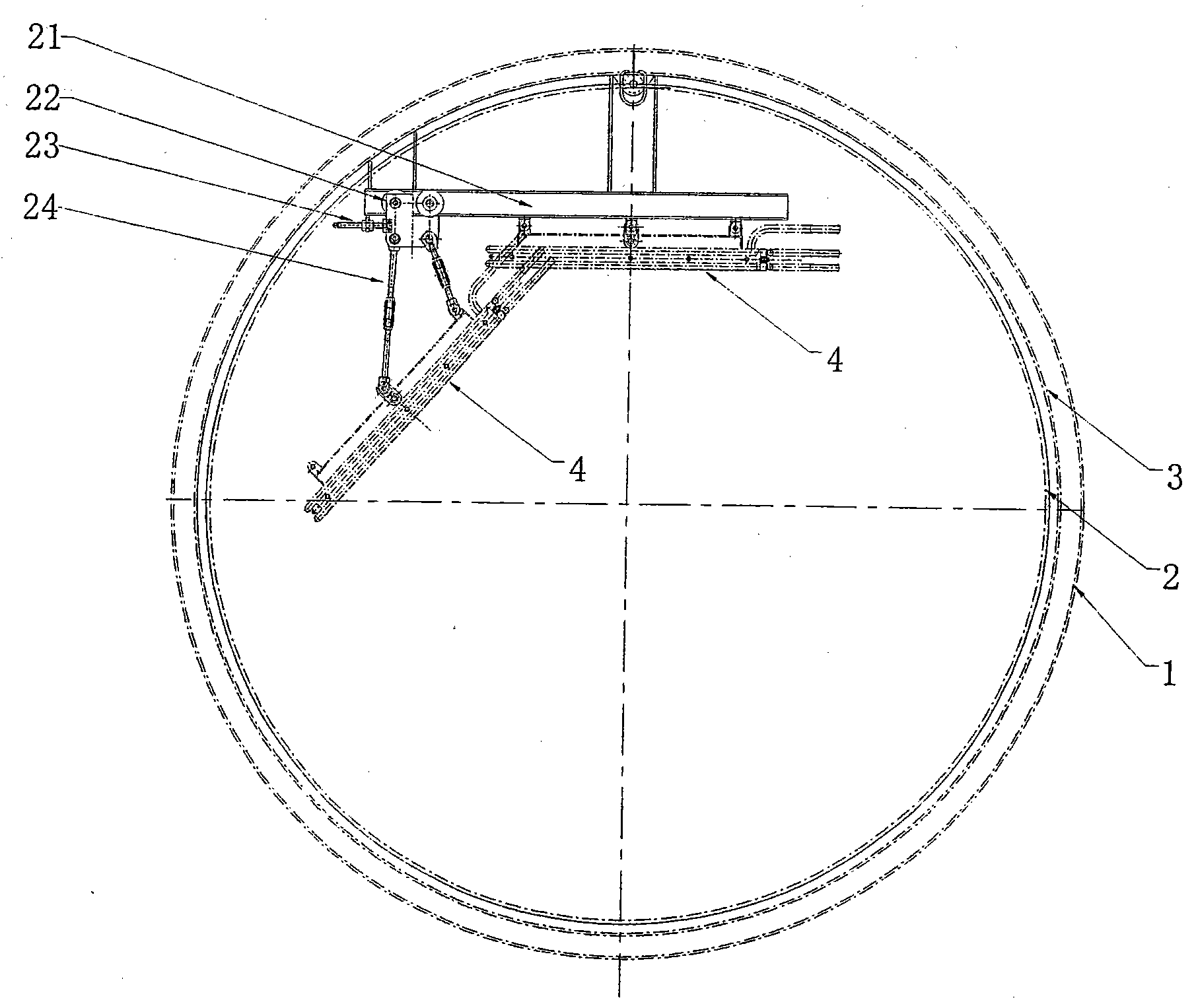

Hoisting and shifting device for the cold screen of the spacecraft radiative refrigerator

InactiveCN105493654BSolve the problem of easy and flexible shiftingSolve lifting problemsCosmonautic thermal protectionSpace environmentEngineering

The invention relates to spacecraft space environment simulation equipment, and discloses a hoisting and shifting device for the cold screen of a spacecraft radiation refrigerator, comprising: the heat sink of the spacecraft space environment simulation equipment is installed inside a vacuum container through a mounting frame, according to the invention, The device also includes: a hoisting slide rail is installed on the installation frame, and a roller limit device is installed at one end; hoisting rollers are installed in the slide rail of the hoisting slide rail, and an adjustable hoisting device for hoisting a large-size cold screen is installed on the lower part of the hoisting slide rail. screw. The invention solves the problem of multi-angle hoisting and displacement of the cold screen inside the vacuum container of the spacecraft space environment simulation equipment, achieves the beneficial effect of improving the reliability of the test equipment, and effectively prevents the cold screen from damaging the surface honeycomb structure due to careless installation operations.

Owner:SHANGHAI INST OF SATELLITE EQUIP

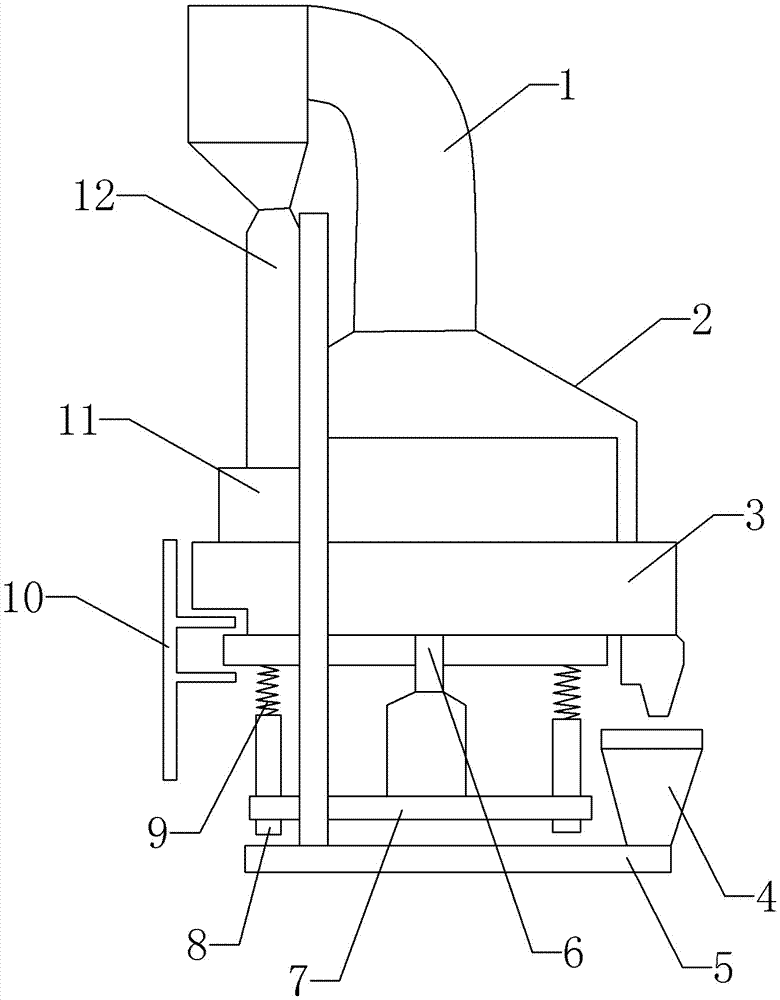

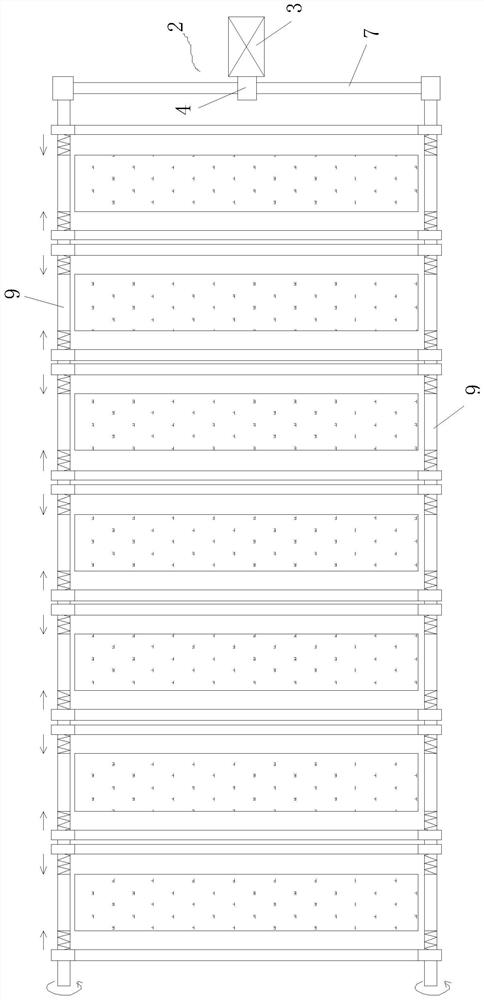

Germ extraction machine capable of adjusting longitudinal height of vibration screen

The invention discloses a germ extraction machine capable of adjusting the longitudinal height of a vibration screen. The problem that in the using process of the vibration screen, shifting happens is solved. The germ extraction machine capable of adjusting the longitudinal height of the vibration screen comprises an air suction system, a feeding mechanism, the vibration screen communicated with the feeding mechanism and a discharging mechanism communicated with the vibration screen, and further comprises a lifting hydraulic cylinder located below the vibration screen; a piston rod of the lifting hydraulic cylinder stretches out to the upper portion of the lifting hydraulic cylinder, and a horizontally-through strip-shaped hole is formed in the end of the piston rod; and a strip-shaped mounting plate is arranged in the strip-shaped hole in a penetrating manner, and the mounting plate is connected to the lower portion of the vibration screen.

Owner:CHONGQING LONGYUE FOOD

Pedestal pan containing plate cover with built-in spraying system

InactiveCN109898615ASolve the weight problemSolve the shiftFlushing devicesBathroom coversEngineeringPersonal hygiene

The invention discloses a pedestal pan containing a plate cover with a built-in spraying system. The pedestal pan is characterized in that a pedestal pan body is provided with a pedestal pan plate cover assembly, the pedestal pan plate cover assembly comprises a fixed base fixed to the pedestal pan body, a seat coaxially arranged on the fixed based and the pedestal pan plate cover, the pedestal pan plate cover is provided with a spray tank fixing structure for positioning and placing a sterilizing and fragrant spray tank, a triggering mechanism capable of triggering the action of a nozzle dueto the opening and closing of the pedestal pan plate cover is arranged at a positon corresponding to the nozzle of the spray tank, and the outlet of the triggered nozzle points at the inner bottom ofthe horizontal seat. The pedestal pan has the advantages that the pedestal pan is designed for houses and personal hygiene awareness culture, a user can be forced to sterilize the pedestal pan throughspraying before and after the use of the pedestal pan, and the user and other people can use a fragrant and sanitary restroom at any time; the pedestal pan is simple and novel in structure, simple tomanufacture, low in manufacturing cost and easy to popularize.

Owner:段冬

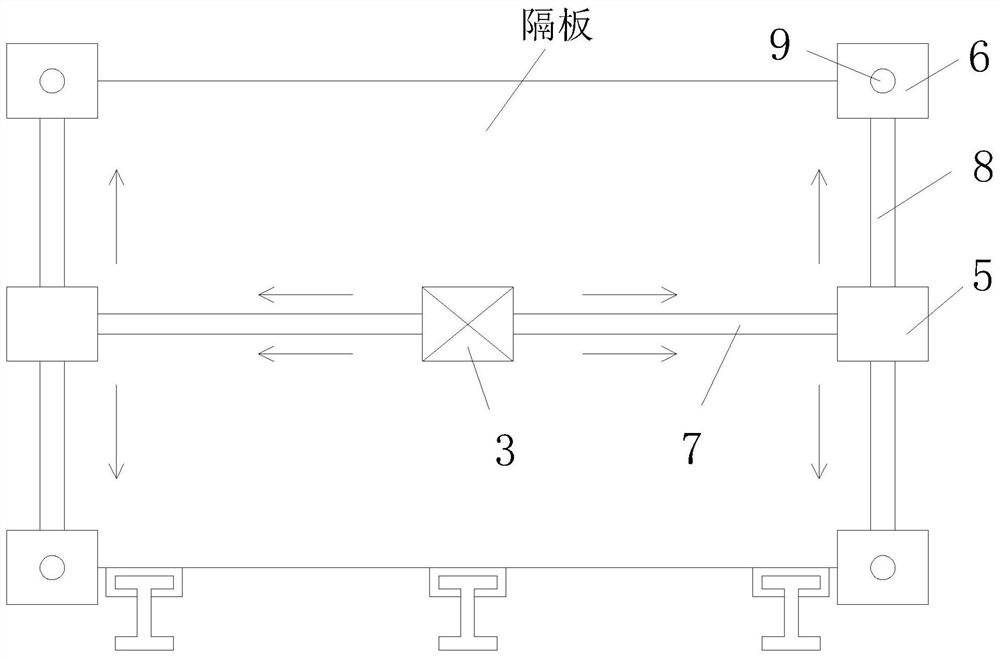

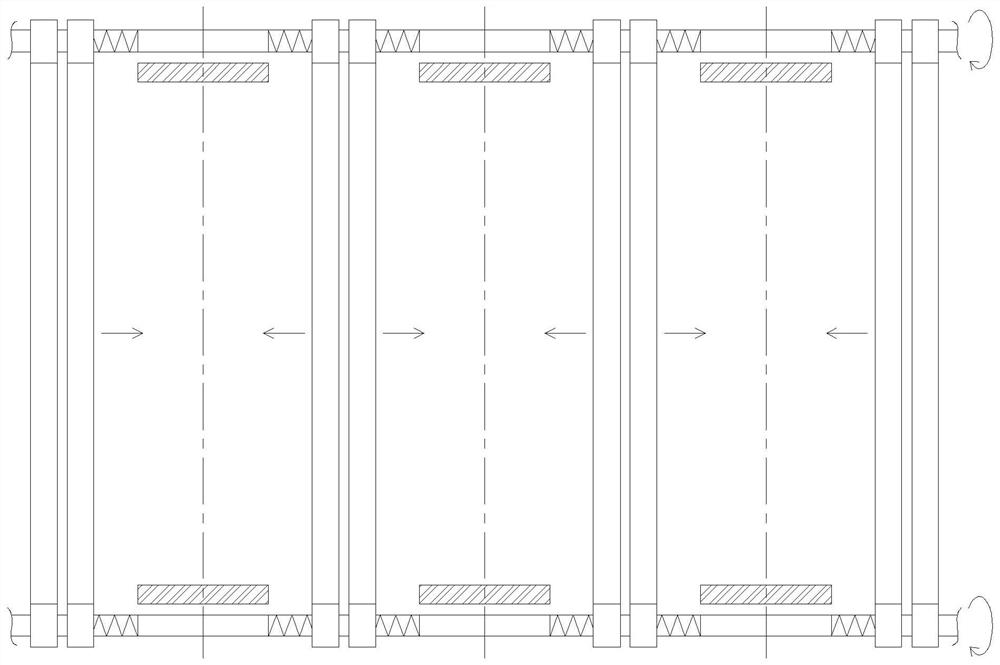

Mold opening and closing mechanism

PendingCN113001722AShort tripIncrease productivityDischarging arrangementMould separation apparatusDrive shaftElectric machinery

The invention discloses a mold opening and closing mechanism. The mold opening and closing mechanism mainly comprises a combined mold and a driving mechanism. When a rotary driving mode is adopted, a motor drives a lead screw to rotate through a reversing apparatus and a transmission shaft, partition plates connected to the lead screw move forwards or backwards along with rotation of the lead screw, and due to the fact that the two partition plates of the same set of combined mold are connected to right-hand threads and left-hand threads respectively, when the lead screw rotates, the two partition plates move face to face or back to back at the same time, and mold closing or mold opening of the mold is achieved; when a direct driving mode is adopted, driving cylinders are arranged at the two sides respectively, the driving cylinder at one side is fixedly connected to the partition plate at one side of the combined mold through a driving frame and a driving rod, and the driving cylinder at the other side is fixedly connected to the partition plate at the other side of the combined mold; and when the driving cylinders at the two sides push towards middle or pull towards two sides at the same time, the partition plates at the two sides of the combined mold move face to face or back to back at the same time, and mold closing or mold opening of the mold is achieved. The mold opening and closing mechanism has the advantages of being simple in structure, convenient to operate and easy to implement.

Owner:FOSHAN YUANFANG GENERAL MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com